Description

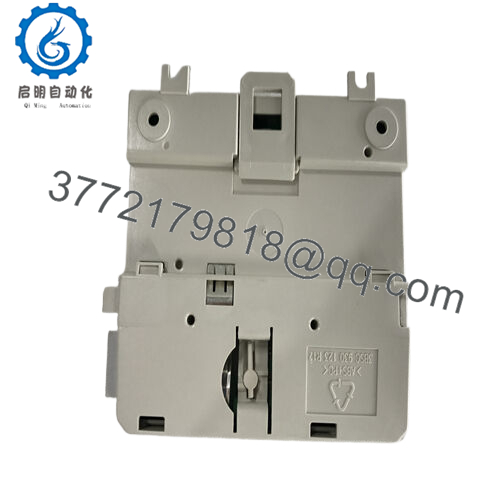

| Model Number | 3BSE008572R1 |

| Brand | ABB |

| Type | 8-Channel Analog Input Module |

| Input Signal Range | 4-20 mA DC, 0-10 V DC (configurable per channel) |

| Input Resolution | 16-bit |

| Operating Temp Range | -25°C to 65°C (-13°F to 149°F) |

| Mounting Style | ABB AC 800M Chassis Mount (1-slot width) |

| Dimensions | 152 mm (H) x 38 mm (W) x 208 mm (D) |

| Weight | 0.60 kg (1.32 lb) |

| Interface/Bus | AC 800M Backplane (100 Mbps data transfer) |

| Compliance | CE, UL 61010-1, IEC 61010-1, ATEX, IECEx, CSA C22.2 No. 142 |

| Supported Protocols | ABB Control Network (for analog data communication) |

| Typical Power Draw | 4.5 W (from backplane 24 V DC supply) |

3BSE008572R1

The ABB 3BSE008572R1 functions as an 8-channel analog input module, playing a vital role in ABB’s automation stack by converting continuous analog signals from field sensors into digital data that the AC 800M controller can process. It connects directly to the AC 800M chassis backplane, enabling high-speed data transfer (up to 100 Mbps) that’s essential for applications requiring real-time process adjustments, such as batch chemical production or turbine speed control. Unlike generic analog input modules, it’s designed for native compatibility with ABB’s Control Builder M software, allowing engineers to easily configure each of the 8 channels to support a wide range of sensor types (e.g., 4-20 mA current loops, 0-10 V DC voltage signals) without relying on third-party tools. This flexibility means the module can adapt to diverse sensing needs within a single system, from monitoring low-pressure gas lines to high-temperature industrial ovens.

3BSE008572R1

The ABB 3BSE008572R1 also includes advanced diagnostic features, such as signal drift detection and sensor open-circuit alerts, which are transmitted in real-time to the controller. This enables maintenance teams to identify potential issues—like a failing pressure sensor or a damaged signal wire—before they escalate to process failures. Additionally, the module features built-in signal filtering to reduce the impact of electrical noise, ensuring consistent and accurate data capture even in high-interference environments (e.g., near large motors or welding equipment).

3BSE008572R1

Main features and advantages:

Choosing the ABB 3BSE008572R1 provides significant long-term value for industrial operations. Engineered for durability, it’s built to withstand extreme temperatures (from -25°C to 65°C), heavy vibration, and electrical interference—making it suitable for harsh environments like offshore oil platforms, mining operations, or steel mills. Its 16-bit input resolution ensures highly accurate signal measurement, which is critical for applications where precise data is essential, such as pharmaceutical manufacturing (where ingredient dosages must be exact) or semiconductor production (where temperature control within ±0.1°C is required). The module’s channel-level configurability also reduces inventory costs and simplifies spare parts management: instead of stocking multiple modules for different sensor types, a single ABB 3BSE008572R1 can handle both current and voltage inputs, cutting down on upfront procurement expenses and storage space.

Another key benefit of the ABB 3BSE008572R1 is its ability to enhance operational efficiency through reduced maintenance requirements. The built-in diagnostic features eliminate the need for manual sensor testing, which can be time-consuming and labor-intensive. For example, if a temperature sensor connected to the module begins to drift outside acceptable limits, the module sends an alert to the AC 800M controller, allowing maintenance teams to replace the sensor during scheduled downtime rather than waiting for a process failure. This proactive approach reduces mean time to repair (MTTR) and minimizes the risk of costly unplanned shutdowns. Additionally, the module’s compatibility with ABB’s AssetVision software enables remote monitoring of signal quality and module performance, further streamlining maintenance workflows and reducing the need for on-site inspections.

Application fields:

The ABB 3BSE008572R1 is widely used across industries that depend on accurate analog signal measurement. In oil and gas production, it’s deployed to monitor wellhead pressure and pipeline flow rates, ensuring safe and efficient hydrocarbon extraction. In power generation (both fossil fuel and renewable), it tracks steam temperature and turbine oil pressure, helping to prevent equipment overheating and ensure grid stability. In chemical processing, it measures chemical concentration levels and reactor pressure, ensuring compliance with safety regulations and maintaining product consistency. Across all these applications, the module’s ability to resist EMI (electromagnetic interference) and operate in extreme temperatures ensures reliable performance, while its high-resolution measurement guarantees accurate data capture. Whether integrated into a standalone AC 800M chassis or a large-scale distributed control system (DCS), the ABB 3BSE008572R1 is a versatile and dependable solution for analog input management.

Related products:

ABB 3BSE008573R1 – 16-channel analog input module, doubling the channel count of the 3BSE008572R1 for high-density sensing applications.

ABB 3BSE008574R1 – 8-channel analog input module with SIL 2 certification, ideal for critical safety loops (e.g., emergency shutdown systems in refineries).

ABB 3BSE008571R1 – 4-channel analog input module, a compact alternative to the 3BSE008572R1 for low-channel-count applications (e.g., small-scale chemical reactors).

ABB 3BSE008575R1 – 8-channel analog input module with extended temperature range (-40°C to 70°C), designed for arctic or desert industrial environments.

ABB 3BSE008576R1 – 8-channel analog input module with Ethernet connectivity, enabling remote data access for distributed automation setups (e.g., offshore wind farms).

ABB 3BSE008570R1 – Older-generation 8-channel analog input module, compatible with legacy ABB MasterPiece controllers (upgrade path to 3BSE008572R1).

ABB 3BSE008577R1 – Add-on signal conditioning module, pairing with the 3BSE008572R1 to enhance signal accuracy in high-noise environments (e.g., near heavy machinery).

ABB 3BSE008578R1 – 8-channel analog input module with higher input impedance, suitable for measuring signals from high-resistance sensors (e.g., pH probes).

Installation and maintenance:

Before installing the ABB 3BSE008572R1, verify compatibility with your ABB AC 800M chassis model (e.g., PM861, PM864, PM865) and ensure the chassis firmware is at least version 6.5—older firmware versions may not support the module’s full diagnostic capabilities or high-speed data transfer features. Calculate the total power consumption of the module and connected sensors to ensure the chassis’s power supply can handle the load (the module draws 4.5 W from the backplane 24 V DC supply). Confirm that the input signals from your sensors (4-20 mA or 0-10 V DC) match the module’s configurable range, and use shielded cables for signal wiring to minimize electrical interference. Additionally, update ABB’s Control Builder M software to version 9.5 or higher; this ensures access to the latest configuration tools, including advanced signal filtering settings and diagnostic dashboards for the ABB 3BSE008572R1.

For ongoing maintenance, schedule monthly checks of the module’s LED status indicators: a steady green “OK” light confirms normal operation, a yellow “WARNING” light signals signal drift beyond acceptable limits, and a red “FAULT” light indicates a sensor open-circuit or module hardware issue (refer to the module’s service manual for specific fault codes). Every three months, inspect the module’s terminal blocks for loose connections or corrosion—tighten wires to 0.45 Nm torque if needed, as loose connections can cause signal degradation. Annually, perform a calibration test using a precision signal generator (e.g., Fluke 725) to verify input accuracy; the module should maintain a measurement error of less than ±0.1% of full scale. In dusty or humid environments, clean the module’s ventilation slots quarterly with a soft brush (avoid compressed air, which can push dust into internal components) to prevent thermal buildup. If the module needs to be replaced, ensure the chassis is in “maintenance mode” (via Control Builder M) to avoid disrupting active analog input channels.

Other ABB product models:

REM615 panel

REM620 N-B-M-N-AA-AB-AB-B-1-B-N-1-XF

REM630E_C UBMNAAAAABBZAZNAX

RET316

RET-5211MRK001530-AE

RET541AB231AAAA

RET543AB243BAAA

RET543AM243AAAB

RET615F

RET620 NBTNAAAAABC1BNN11G

RET650

RET650 1KHL160055R0001A

RET670 1MRK002816-AC

RET670 1MRK002816-AC

RET670 1MRK002816-AB

RET670 1MRK002816-AC

RET670 1MRK002816-AC

RET670 in stock

REU610

REU610 CVVHCNR02

REU615B

REX521 GHHPSH07G

REX521GHHPSH50G

RF533 3BSE014227R1

RF615 3BHT100010R1

RHD250-10

RLM01

ABB S-073N 3BHB009884R5211

ABB S-093H 3BHB030478R0309

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626