Description

| Model Number | 3BHL000391P0101 |

| Brand | ABB |

| Type | Turbine-Optimized Power Interface Module |

| Input Voltage | 110V AC (50/60Hz) or 24V DC (turbine auxiliary power) |

| Output Voltage | Regulated 24V DC (±0.2% tolerance); 5V DC auxiliary for sensors |

| Output Power | 50W (24V DC); 5W (5V DC) |

| Operating Temp Range | -10°C to 70°C (14°F to 158°F) |

| Mounting Style | ABB Turbine Control Cabinet Backplane (vibration-resistant) |

| Dimensions | 35mm (W) x 120mm (H) x 130mm (D) |

| Weight | 0.38kg (0.84lbs) |

| Interface/Bus | 1x Profinet (for DCS integration), 1x ABB Turbine Bus, 1x RS485 (diagnostics) |

| Protection Features | Overvoltage (2kV transient suppression), overcurrent, short-circuit, reverse polarity |

| Compliance | CE, UL 508, RoHS, IEC 61000-6-2 (EMC), IEC 60034-1 (turbine compatibility) |

| Supported Protocols | Profinet, ABB Turbine Bus; Compatible with Control Builder M v8.0+, Ability System 800xA |

| Typical Power Draw | 42W (full load, 24V DC); 3W (standby) |

3BHL000391P0101

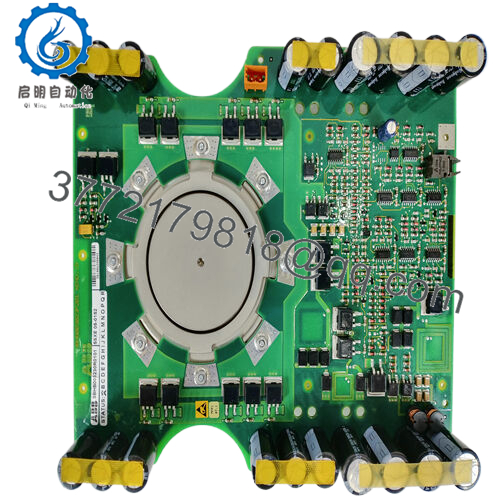

The ABB 3BHL000391P0101 acts as the critical power hub in ABB’s turbine automation stack, connecting three key elements: the turbine’s auxiliary power source (typically 110V AC or 24V DC), ABB’s turbine control components (e.g., AC 800M TCS controllers, speed sensors, and hydraulic valve drivers), and plant-wide DCS networks (e.g., ABB Ability System 800xA). Unlike generic power converters, it features dual-stage voltage stabilization: first, it conditions fluctuating auxiliary power (filtering out transients up to 2kV) to a steady intermediate voltage, then converts it to the precise 24V DC required by turbine control components—maintaining a tolerance of ±0.2% even during turbine startup or load swings.

3BHL000391P0101

This stabilization is critical for components like turbine speed controllers, which require ultra-consistent power to maintain speed accuracy within ±0.01% of rated RPM. The module mounts directly to ABB’s turbine control cabinet backplanes (designed to withstand turbine vibration up to 4g peak, per IEC 60068-2-6) and includes integrated communication ports (Profinet and ABB Turbine Bus) that enable real-time power status monitoring via ABB’s Control Builder M software. A key advantage is its “turbine mode” optimization: it automatically adjusts power delivery profiles during startup (prioritizing critical components like lube oil pumps) and normal operation (balancing power across all control systems), ensuring alignment with turbine operational phases. By stabilizing power and enabling integration, the ABB 3BHL000391P0101 forms the backbone of reliable turbine control, keeping precision components powered consistently and connected to broader plant systems.

3BHL000391P0101

Main features and advantages:

Choosing the ABB 3BHL000391P0101 delivers tangible value that directly addresses turbine operational pain points. Its dual-stage voltage stabilization eliminates the need for external power filters or backup batteries—components that add cost, complexity, and failure points to turbine control systems. For gas power plant turbines, this translates to smoother startups: the module maintains stable power to speed controllers during the critical 0–30% RPM phase, reducing startup time by up to 15% compared to systems using generic power converters. The module’s turbine-specific optimization also improves long-term reliability: its vibration-resistant design and transient suppression protect against the harsh conditions of turbine enclosures, resulting in a mean time between failures (MTBF) of over 180,000 hours—far exceeding standard industrial power modules. For engineers, this means fewer unplanned turbine shutdowns: in a 50MW gas turbine, each hour of downtime costs approximately $25,000, so the module’s reliability directly reduces operational expenses. Additionally, its seamless integration with ABB’s turbine and DCS ecosystems simplifies commissioning: it auto-detects connected control components and configures power delivery profiles, cutting setup time by 30% compared to manual configuration of multiple power devices.

Application fields:

The ABB 3BHL000391P0101 is purpose-built for turbine-centric industries, excelling in three key use cases. In gas-fired power plants, it’s deployed in combined-cycle turbine control systems, stabilizing auxiliary power from the turbine’s generator during load changes (e.g., shifting from 50% to 100% output) to ensure speed controllers and emissions monitoring systems remain accurate—critical for meeting grid frequency requirements and environmental regulations. In marine propulsion systems (e.g., large cargo ships or naval vessels), it powers ABB’s marine turbine control components, withstanding the harsh vibration and temperature swings of engine rooms while converting variable DC auxiliary power (from the ship’s main generator) to stable 24V DC for valve positioners and thrust monitors. It’s also vital in industrial steam turbines (used in pulp and paper mills or chemical plants), where it bridges the turbine’s 110V AC auxiliary power to the mill’s 24V DC DCS network—enabling real-time monitoring of turbine efficiency and integration with mill-wide production scheduling systems. In each scenario, the ABB 3BHL000391P0101 meets the unique demands of turbine operation: its transient suppression handles power fluctuations, its vibration resistance ensures durability, and its communication ports enable seamless integration—keeping turbines running efficiently and safely.

Related products:

ABB 3BHL000391P0102 – Higher-power variant (80W 24V DC output) for large-scale turbines (e.g., 100MW+ steam turbines).

ABB 3BHL000391P0103 – DC-input-only model (48V DC in, 24V DC out) for battery-backed turbine control systems (e.g., remote power plants).

ABB 3BHL000391P0104 – Extended-temperature variant (-25°C to 75°C) for arctic or desert turbine installations.

ABB 3BHL000391P0105 – Isolated-output model (2.5kVrms isolation) for turbine systems in high-voltage power plants.

ABB 3BHL000391P0101 + 3BHL000392P0101 – Bundle with power monitoring module for real-time turbine power usage tracking.

ABB 3BHL000391P0106 – Redundant power interface module for SIL 2 turbine safety systems (e.g., overspeed protection).

ABB 3BHE013299R0002 – Compatible turbine control power unit, optimized for use with the ABB 3BHL000391P0101 in AC 800M TCS.

ABB 3BHE014185R0001 UUD148AE01 – I/O module that pairs with the power interface for turbine sensor data acquisition.

Installation and maintenance:

Before installing the ABB 3BHL000391P0101, first verify compatibility with your turbine’s auxiliary power source: confirm whether the input is 110V AC or 24V DC, as using the wrong input type can damage the module and connected control components. Next, calculate the total power load of connected turbine control devices (e.g., speed sensors, valve drivers, vibration monitors) to ensure it does not exceed the 50W max output—overloading can trigger the module’s protective shutdown, which may cause an unexpected turbine trip. During setup, use ABB’s Control Builder M software to select the appropriate “turbine mode” (gas, steam, or marine) – this configures the module’s power stabilization profiles to match the turbine’s operational characteristics (e.g., slower startup ramps for steam turbines). Conduct a transient test by simulating a voltage spike (using a signal generator) to confirm the module’s suppression feature works—this ensures it can handle real-world power fluctuations during turbine operation. For maintenance, perform monthly checks of the module’s LED status indicators: a steady green light confirms normal operation, while a red light signals a fault (e.g., overcurrent, overheating) that requires immediate attention. Every six months, inspect the module’s backplane connector for corrosion (common in marine or steam turbine environments) and clean it with a dry, lint-free cloth—corrosion can cause voltage drops that disrupt turbine control. Annual functional testing, using a variable load bank to simulate peak turbine control demand, ensures the module’s output regulation (±0.2% tolerance) remains consistent over time.

Other ABB product models:

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB UAD155A0111 3BHE029110R0111

ABB 1TGE120040R0010

ABB DCF506-0140-51-0000000

ABB PCD530

ABB 1TGE120016R0104

ABB 1MRK000614-AB

ABB 5SHY35L4510

ABB PYT0450W071A

ABB DKTFM418B 3BHB015651P0001

ABB REF620E-1G NBFNAANNNEA1BNF11G

ABB PM858K02 3BSE082896R1

ABB PM902F 3BDH001000R0001

ABB KSD211B101 3BHE022455R1101

ABB PM863K02 3BSE088382R1

ABB SM812K01 3BSE072270R1

ABB UNS0867 HIEE405246R0002

ABB El3020 URAS26

ABB PM803F

ABB REF601BE446BD1NH

ABB 3BHE022287R0001

ABB PFTL101A-2.0KN 3BSE004172R1

ABB PTPU-02 3HNA023148-001

ABB UNITROL1020

ABB 3HAC028357-001

ABB 3BSE003832R1 SC510

ABB LM200

ABB SPAJ110C

ABB 1KHL178016R0001F

ABB 1KHL160038R0104D

ABB UP10C01000

ABB LD800HSE 3BDH000320R02

ABB 5SHY35L4520 5SXE10-0181

ABB VP01 2VAA008172R01

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626