Description

What This Product Solves

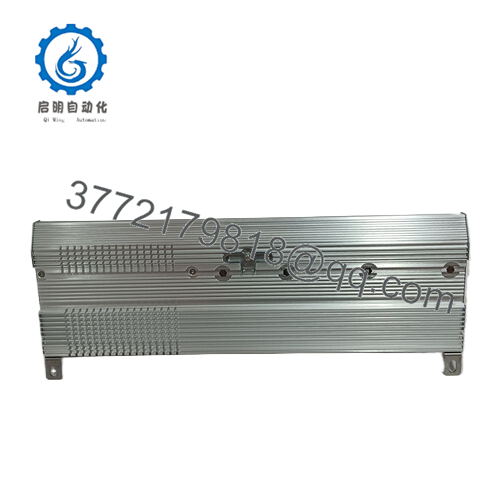

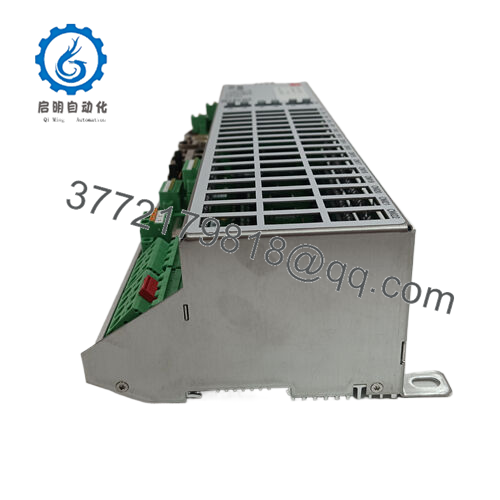

The ABB 3BHE046836R0101 GFD563A101 is a high-performance industrial control module designed specifically for advanced automation applications requiring precise control and real-time monitoring. This module solves the challenge of managing complex processes with accuracy and stability, particularly in environments like manufacturing, power generation, and process industries where system reliability and uptime are critical. It provides robust control capabilities that optimize process efficiency and reduce the risk of downtime.

This controller is essential for applications requiring seamless integration with other control devices and networks, ensuring smooth communication and precise process execution. Keywords such as “industrial automation,” “process control,” “real-time monitoring,” and “high reliability” highlight its critical role in modern automation solutions.

How the Product Works & Fits into a System

The ABB 3BHE046836R0101 GFD563A101 module functions as an interface and control unit within ABB’s Symphony Plus and Advant series automation platforms. It supports dual-port Ethernet communication for redundancy and enhanced network fault tolerance, ensuring continuous data flow even in challenging conditions. Operating on 24 V DC power, it features industrial-grade components built to withstand harsh environments, including temperature extremes and electromagnetic interference.

Physically compact and designed for rack mounting, this module integrates easily within complex process control systems, facilitating data exchange between sensors, actuators, and supervisory control systems. Its modular architecture supports flexible scalability and simplifies maintenance while offering functionalities such as PID control, state monitoring, and feedback loops to maintain process accuracy.

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | 3BHE046836R0101 / GFD563A101 |

| Brand | ABB |

| Type | Industrial Control Module |

| Power Supply | 24 V DC |

| Communication | Dual-port Ethernet (redundant) |

| Operating Temp Range | Industrial grade |

| Dimensions | Standard rack mount size |

| Functions | PID control, real-time monitoring, feedback control |

| Compatibility | ABB Symphony Plus, Advant series |

3BHE046836R0101 GFD563A101

3BHE046836R0101 GFD563A101

Real-World Benefits

The ABB 3BHE046836R0101 GFD563A101 ensures smooth, reliable control and communication within high-demand industrial automation settings, delivering consistent performance and reducing unplanned downtime. Its dual Ethernet ports provide network redundancy, protecting critical data flows from interruptions and enabling fast fault detection and recovery.

The module’s robust industrial design minimizes maintenance needs and supports long-term operational stability. Engineering teams benefit from its flexibility and integration ease, which reduce setup complexity and support rapid troubleshooting, enhancing overall process management efficiency.

Typical Use Cases

Primarily used in power generation plants, chemical processing, and large-scale manufacturing operations, the ABB 3BHE046836R0101 GFD563A101 excels in applications that require precise process control with continuous data availability. It supports real-time adjustments and fault-response strategies needed to maintain safety, efficiency, and product quality in automated industrial environments.

Compatible or Alternative Products

3BHE046836R0101 GFD563A101 – ABB Ethernet control and monitoring module.

3BHE039426R0101 UF C912 A101 – IGCT module for power control.

216AB61 HESG324013R100 – Digital output module for protection systems.

07KT98C GJR5253100R028 – Advant Controller 31 basic unit.

DSAI133A 3BSE018290R1 – High-density analog input module.

Setup Notes & Maintenance Insights

Installation requires verification of 24 V DC power availability and compatible Ethernet network infrastructure. Ensure proper rack space and ventilation to maintain optimal operating conditions. Configure dual Ethernet ports for redundancy as per system architecture.

Regular maintenance includes monitoring network status and system diagnostics, updating firmware, and inspecting physical connections to ensure signal integrity. These practices help maintain high reliability and prevent communication interruptions.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626