Description

Real-World Use & Application Scenarios

In large-scale industrial plants, reliability and control precision are not just desirable—they are essential to sustaining continuous operation. Facilities such as petrochemical refineries, pulp and paper mills, steel processing plants, and power generation stations all depend on digital control systems to keep equipment running safely and at maximum efficiency. When a drive system or process automation unit encounters instability, even a minor fault can lead to unexpected downtime, production losses, or costly maintenance interventions. This is exactly the environment where the ABB 3BHE037864R0104 proves its worth.

The module is used in industrial automation environments where engineers need to balance robust control with fault-tolerant operation. It often serves as part of ABB’s distributed control systems (DCS) and high-performance drive platforms, ensuring precise regulation of motors, actuators, and auxiliary processes. For industries that operate 24/7—cement production lines, mining operations, and high-throughput chemical plants—system stability is directly tied to profitability. In these contexts, the ABB 3BHE037864R0104 supports not only continuous operation but also provides a dependable interface that reduces error margins in real-time process execution.

Its application extends into energy-intensive sectors such as gas liquefaction and offshore platforms, where the ability to integrate seamlessly with ABB drive technologies gives engineers confidence in both performance and safety compliance. By handling complex control tasks, managing data exchanges, and maintaining synchronization within distributed systems, the ABB 3BHE037864R0104 ensures plant operators achieve both regulatory compliance and long-term asset reliability.

Ultimately, this module addresses the universal industrial challenge: achieving high throughput while minimizing risk of disruption. That combination of rugged design and smart functionality explains why the ABB 3BHE037864R0104 is trusted in so many mission-critical environments.

Product Introduction & Positioning

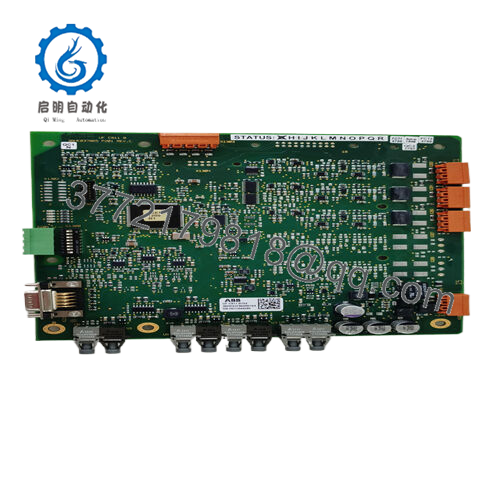

The ABB 3BHE037864R0104 is a precision-engineered control and interface module designed to integrate seamlessly within ABB’s automation ecosystem. Functioning as a core component in ABB’s advanced distributed control and drive systems, it provides the essential link between field devices, controllers, and higher-level supervisory systems. Its role is to translate complex operational data into actionable control signals, thereby enabling consistent and stable process performance.

Within a DCS or drive architecture, the ABB 3BHE037864R0104 often operates as a modular element mounted within control cabinets. Engineers value it because it simplifies system expansion and modernization projects without requiring full platform overhauls. Whether it is part of a turbine control system, a variable speed drive package, or a process automation rack, it fits neatly into ABB’s layered approach to industrial control—field input, system logic, and output execution.

Its design supports compatibility with a wide range of ABB legacy and current platforms, making it an attractive choice for operators who need long-term lifecycle support. For system integrators, the module reduces project complexity: it adheres to ABB’s standardized interfaces, meaning less custom wiring, fewer integration headaches, and more predictable commissioning. For plant maintenance teams, its modularity makes it straightforward to replace without prolonged system downtime.

In short, the ABB 3BHE037864R0104 is not just a replacement spare—it is a vital component that secures continuity and reliability in high-value control systems.

Key Technical Features & Functional Benefits

One of the most notable strengths of the ABB 3BHE037864R0104 is its capacity to sustain operational stability even under demanding load conditions. Industrial automation systems often face unpredictable variations in demand, voltage fluctuations, and environmental stresses. This module is engineered to maintain accuracy and synchronization in such circumstances, ensuring that critical processes remain under control without lapses.

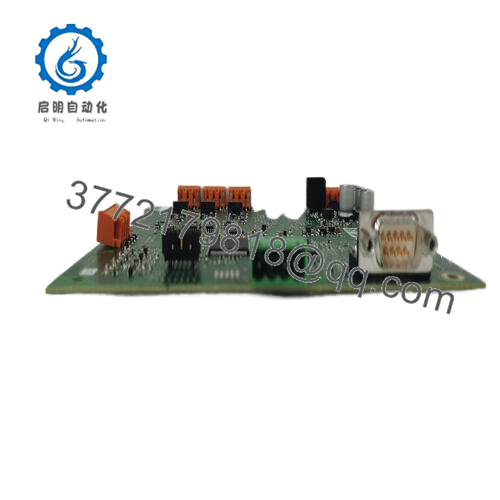

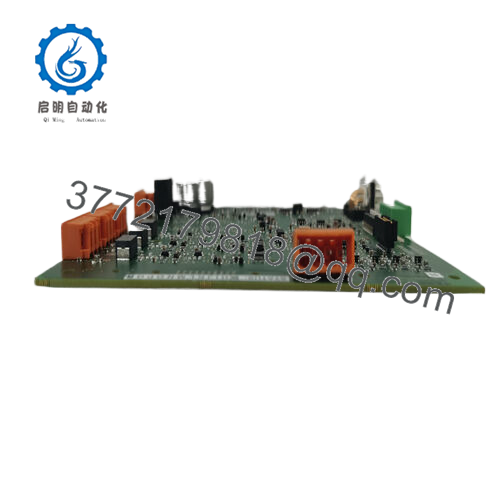

From a hardware standpoint, the ABB 3BHE037864R0104 benefits from a rugged construction that resists both electrical noise and mechanical vibration. Its form factor is designed for rack or cabinet mounting, occupying minimal space while offering secure connectivity. Engineers working in tight electrical rooms or on offshore platforms value these physical considerations because they directly reduce installation and service challenges.

Compatibility is another defining attribute. The module integrates effortlessly with other ABB components, making it versatile in projects that require either system upgrades or full-scale retrofits. Its communication capabilities support seamless data transfer across multiple layers of a control hierarchy, thereby reducing latency and enhancing overall plant responsiveness.

Finally, long-term reliability is embedded into its design. With robust cooling methods, optimized thermal dissipation, and adherence to international quality standards, the ABB 3BHE037864R0104 minimizes failure risks over its service life. This directly translates into lower maintenance overheads, fewer emergency shutdowns, and greater return on investment for operators.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 3BHE037864R0104 |

| Brand | ABB |

| Type | Control/Interface Module |

| Power Supply | 24 VDC nominal (system supplied) |

| Operating Temperature | 0 °C to +55 °C |

| Mounting | Rack or cabinet installation |

| Dimensions | Compact ABB modular format |

| Weight | Approx. 0.8 – 1.2 kg |

| Interfaces | System backplane, field I/O ports |

| Certifications | CE, UL, industrial compliance |

| Cooling | Passive with optimized airflow |

| Environmental Rating | Designed for industrial settings, shock and vibration tested |

3BHE037864R0104

3BHE037864R0104

Related Modules or Compatible Units

-

ABB 5SHX1960L0006 – High-power drive module that complements the control functions of the 3BHE037864R0104 in large motor applications.

-

ABB 3BHB016120R0002 – Processor module that provides enhanced computational power for distributed control systems.

-

ABB 3BHE019719R0101 – Earlier generation interface board, often replaced during system upgrades involving the 3BHE037864R0104.

-

ABB GVC736BE101 – Auxiliary unit supporting extended communication protocols for ABB automation platforms.

-

ABB 3BHE032025R0102 – Module designed for high-temperature operation, compatible with similar control environments.

-

ABB DSAO120AK01 – Analog input module that integrates with ABB control racks to provide precise sensor data acquisition.

-

ABB DSPC174 3BSE005461R1 – Processor card used in ABB AC 800M systems, often paired with interface modules for enhanced logic control.

Installation Notes & Maintenance Best Practices

Before installing the ABB 3BHE037864R0104, engineers should ensure that control cabinet dimensions, grounding arrangements, and environmental conditions are properly evaluated. Adequate clearance around the module is important to allow airflow and prevent overheating. Cable routing must be carefully managed to minimize electromagnetic interference, particularly in drive-heavy environments. Verifying system compatibility and firmware versions before installation helps reduce commissioning delays.

Once in service, the module requires only minimal maintenance, but preventive practices are highly recommended. Regular visual inspections should be carried out to check for loose connectors, dust buildup, or early signs of wear. Signal diagnostics and periodic firmware updates are advised to ensure compatibility with evolving ABB system standards. Plant operators who schedule these tasks as part of a planned maintenance program will extend the lifecycle of the ABB 3BHE037864R0104 and avoid unexpected downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626