Description

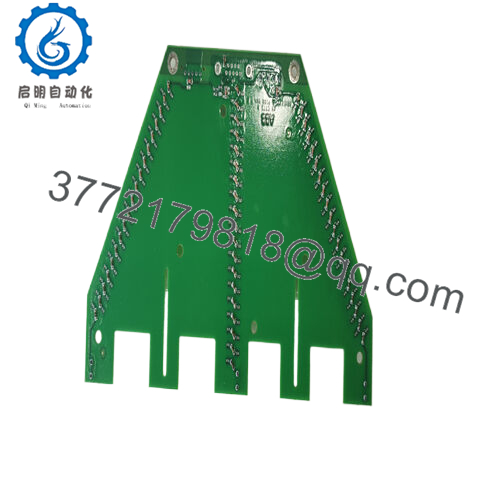

- 3BHE032285R0102

| Specification | Details |

|---|---|

| Model Number | 3BHE032285R0102 |

| Brand | ABB |

| Type | High Voltage Divider Board (HVD) |

| Input Voltage | 200-690 V AC/DC |

| Operating Temp Range | -10°C to +50°C |

| Mounting Style | Panel Mount in Drive Cabinet |

| Dimensions | 150 x 100 x 25 mm (approx.) |

| Weight | 0.3 kg |

| Interface/Bus | ACS2000 Internal Backplane |

| Compliance | CE, RoHS, IP20 |

| Supported Protocols | Modbus, Profibus, DeviceNet |

| Typical Power Draw | 5 W |

The ABB 3BHE032285R0102 operates as a specialized high-voltage interface within drive control architectures, taking raw high-voltage inputs from field sources like generators and scaling them down proportionally for safe processing by the system’s controller. Leveraging precision resistive networks, it divides voltages—typically handling ranges up to 690 V—while providing galvanic isolation to shield sensitive downstream electronics from transients. This isn’t passive division; integrated diagnostics monitor divider integrity, alerting via status signals if drift exceeds thresholds, which helps maintain loop accuracy over extended runs.

Positioned in the mid-tier of the automation stack, it slots directly into ACS2000 series drive cabinets, interfacing with the main processor board over internal buses like the drive’s proprietary backplane. From there, conditioned signals flow to the central PLC or DCS, such as ABB’s 800xA platform, where they’re used for real-time adjustments in vector control modes. It supports redundancy through dual-channel configurations, allowing failover without process interruption—a key for continuous operations. Protocols like Modbus or Profibus come into play for configuration and data exchange, making it adaptable to hybrid networks where legacy equipment meets modern Ethernet/IP overlays.

In a full system, you’d typically pair the 3BHE032285R0102 with power converter modules and feedback sensors in a modular enclosure, ensuring it aligns with the drive’s overall I/O architecture. Configuration via ABB’s Drive Composer tool lets you fine-tune gain factors and calibration curves upfront, minimizing field tweaks. This forward-thinking design reduces latency in voltage feedback loops, proving invaluable in dynamic environments where precise torque or speed regulation hinges on unerring signal fidelity.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626