Description

Real-World Use & Application Scenarios

Industrial plants rarely operate in ideal conditions. Heat, vibration, electrical noise, and constant demand put continuous stress on control equipment. For facilities like petrochemical complexes, pulp and paper mills, or large-scale water treatment plants, the ability to maintain reliable automation depends heavily on modules that link the control system to real-world processes. That is where the ABB 3BHE032025R0101 PCD235A101 finds its place.

This module is commonly deployed in distributed control system (DCS) environments where it serves as a bridge between sensors, actuators, and supervisory logic. For example, in a refinery’s distillation unit, it helps maintain temperature and flow parameters within strict operating limits. In a hydropower station, it supports stable turbine control, ensuring efficiency even under fluctuating load conditions. Manufacturing plants also rely on it to maintain synchronization across production lines, reducing downtime and ensuring consistent product quality.

The ABB 3BHE032025R0101 PCD235A101 is valued not just for its technical capabilities but also for its role in long-term operational stability. Engineers select it because it provides dependable signal handling, integrates smoothly into ABB’s automation ecosystem, and performs reliably under industrial stresses. In real-world terms, it helps operators prevent costly shutdowns, protect assets, and ensure compliance with regulatory standards for process safety.

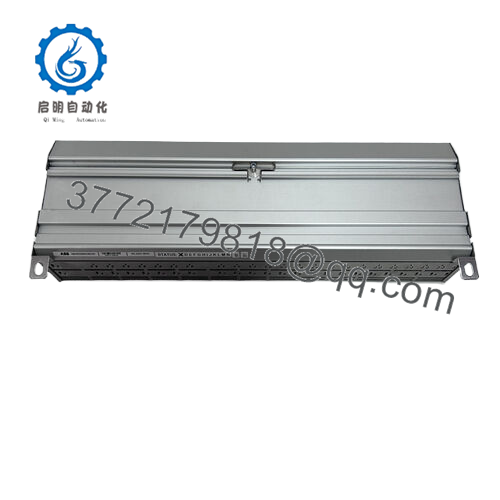

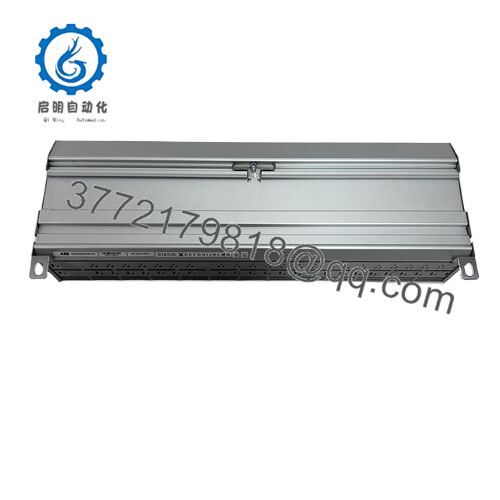

3BHE032025R0101 PCD235A101

3BHE032025R0101 PCD235A101

3BHE032025R0101 PCD235A101

Product Introduction & Positioning

The ABB 3BHE032025R0101 PCD235A101 is an advanced control module designed for integration into ABB’s distributed control system platforms. Its primary role is to process input signals, manage communication with the system controller, and issue precise output commands to connected devices. In doing so, it ensures that real-world process variables are consistently monitored, adjusted, and aligned with supervisory setpoints.

As part of ABB’s PCD series, this unit is positioned to handle mid-to-high level process control demands, offering robust hardware design combined with compatibility across ABB DCS solutions. Its design philosophy emphasizes both technical reliability and lifecycle support, making it a smart choice for industries where automation must remain operational for decades, not just years.

For system architects and integrators, the ABB 3BHE032025R0101 PCD235A101 slots into the I/O and communication layer of the automation stack. It reduces integration complexity by leveraging ABB’s standardized communication protocols, and it provides built-in diagnostic functions that simplify commissioning and troubleshooting. This makes it an asset not only in new installations but also in retrofit projects where legacy equipment is being modernized without full system replacement.

Key Technical Features & Functional Benefits

The ABB 3BHE032025R0101 PCD235A101 stands out for its balance of processing performance and rugged physical design. It delivers rapid signal response times, ensuring that process variables are adjusted with minimal delay. In critical applications such as turbine control or high-speed batch processing, this fast reaction can make the difference between stable operation and costly deviations.

Hardware durability is another defining strength. The unit is engineered with industrial-grade components capable of tolerating temperature fluctuations, mechanical vibration, and electrical interference. Its compact form factor simplifies cabinet installation, while its secure connectors ensure stable operation even in demanding plant environments.

Compatibility across ABB’s DCS families makes the ABB 3BHE032025R0101 PCD235A101 a versatile investment. It supports integration without requiring complex customization, allowing operators to expand or upgrade their automation systems with minimal disruption. Engineers also benefit from built-in diagnostic features, which reduce the time spent troubleshooting and make preventive maintenance more effective.

Finally, ABB’s emphasis on lifecycle reliability means the module is designed for long service life. Efficient thermal management, durable construction, and supported firmware updates all contribute to minimizing unplanned downtime. For plant operators, this translates into improved uptime and predictable maintenance planning.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 3BHE032025R0101 PCD235A101 |

| Brand | ABB |

| Type | Control Module |

| Power Supply | 24 V DC (nominal) |

| Operating Temperature | –20 °C to +55 °C |

| Mounting | DIN-rail or cabinet-mounted |

| Dimensions | 135 mm x 45 mm x 180 mm (approx.) |

| Weight | 0.9 kg |

| Interfaces | Digital/analog I/O, system bus |

| Certifications | CE, UL, IEC industrial compliance |

| Cooling | Passive convection |

| Environmental Rating | IP20 (when housed in cabinet) |

Related Modules or Compatible Units

-

ABB PCD231B101 3BHE025541R0101 – Companion module from the same series, often paired in control applications.

-

ABB PCD230A101 3BHE022291R0101 – A related unit providing complementary process control functions.

-

ABB PCD232A 3BHE022293R0101 – Expanded variant offering increased I/O handling capacity.

-

ABB PFEA111-20 3BSE028140R0020 – Communication interface module used for system integration.

-

ABB REF615E – Protection relay designed to work within ABB’s DCS environments.

-

ABB DSPC174 3BSE005461R1 – Processor module offering higher computational capacity for advanced tasks.

-

ABB CI522AK04 – Communication interface that enables broader system connectivity.

Installation Notes & Maintenance Best Practices

Before installing the ABB 3BHE032025R0101 PCD235A101, it is important to ensure cabinet space is adequate for both physical mounting and airflow. Proper grounding practices must be observed to avoid electromagnetic interference, and power supply wiring should follow ABB’s recommended guidelines. Signal and power cables should be routed separately to prevent noise coupling.

Maintenance should focus on regular inspection of connectors and housing for signs of wear, as well as verification of input/output calibration. Diagnostic checks built into the module should be executed at defined intervals, allowing operators to identify issues before they impact production. Firmware updates, when released by ABB, should be applied promptly to ensure security and performance. With these practices, the ABB 3BHE032025R0101 PCD235A101 can deliver reliable service throughout its expected lifecycle.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626