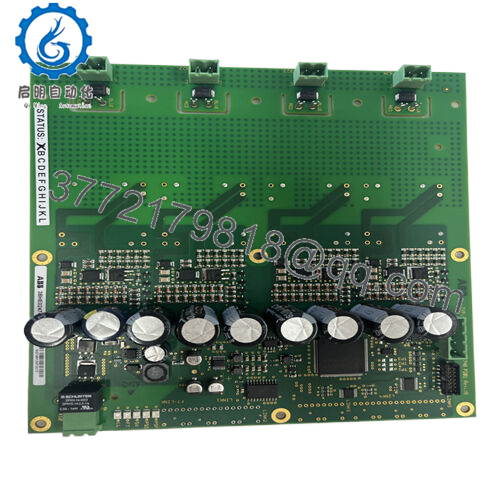

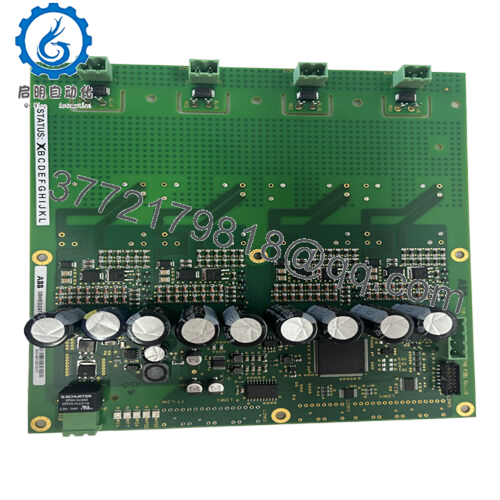

Description

| Model Number | 3BHE024747R0101 |

| Brand | ABB |

| Type | Redundant Power Supply (SIL 3-Certified) |

| Input Voltage | 110/230V AC (auto-ranging, 50/60Hz); 24V DC backup input |

| Output Voltage | Regulated 24V DC (±0.3% tolerance) |

| Output Power | 100W (total); 50W per redundant path |

| Safety Certification | IEC 61508 (SIL 3), IEC 61511 (SIL 3), TÜV SÜD Certified |

| Operating Temp Range | -20°C to 75°C (-4°F to 167°F) |

| Mounting Style | ABB Safety Cabinet Backplane (compatible with AC 800M HI/SIS enclosures) |

| Dimensions | 48mm (W) x 150mm (H) x 160mm (D) |

| Weight | 0.85kg (1.87lbs) |

| Interface/Bus | RS485 Diagnostic Port (safety-rated); compatible with ABB Safety Bus |

| Fault Tolerance | Active redundancy (2x parallel paths), <100ms failover |

| Compliance | CE, UL 508, RoHS, IEC 61000-6-4 (EMC for safety systems) |

| Supported Protocols | ABB Safety Bus; Compatible with Safety Builder v8.0+ |

| Typical Power Draw | 85W (full load, redundant mode); 45W (half load, single path) |

3BHE024747R0101

The ABB 3BHE024747R0101 operates as the power backbone for ABB’s safety automation stack, converting incoming AC power (110/230V AC, auto-ranging) into stable 24V DC power for safety-critical components—including the ABB 3BHE023784R0001 safety I/O module, AC 800M HI SIS controllers, and emergency shutdown relays. Unlike standard industrial power supplies, it features 100% active redundancy: two independent power conversion paths run in parallel, with automatic failover (under 100ms) if one path develops a fault (e.g., a failed rectifier or capacitor). This ensures zero power interruption to safety loops—even during component failures.

3BHE024747R0101

It mounts to ABB’s dedicated safety cabinet backplanes, with a compact design that saves space in dense SIS enclosures. A key advantage is its built-in safety-focused diagnostics: it continuously monitors input voltage, output load, and internal temperature, alerting operators via ABB’s Safety Builder software to anomalies like voltage sags or overheating before they escalate to failures. The module also supports “safe power-down” logic: in the event of a critical fault (e.g., input power loss), it triggers a controlled shutdown of connected safety components, ensuring they default to preconfigured safe states (e.g., closing isolation valves) instead of abruptly losing power. By acting as a fault-tolerant power source for ABB’s safety ecosystem, the ABB 3BHE024747R0101 ensures safety loops remain operational even in the face of power system disruptions.

Main features and advantages:

Choosing the ABB 3BHE024747R0101 delivers safety and operational value that goes far beyond basic power conversion. Its SIL 3 certification eliminates the need for third-party power safety validation, cutting compliance costs by up to 25% compared to using non-certified redundant supplies that require custom documentation. The module’s active redundancy directly reduces unplanned downtime: in industries like oil refining, where safety loop outages can halt production for days, the ABB 3BHE024747R0101 ensures SIS power remains intact, avoiding losses of $100,000+ per hour of downtime. For long-term reliability, its rugged design—including vibration resistance up to 5g peak (per IEC 60068-2-6) and wide temperature range—thrives in harsh environments, from the high humidity of chemical plants to the extreme cold of arctic offshore platforms. This durability translates to a mean time between dangerous failures (MTBDF) of over 1.2 million hours—far exceeding industry standards for safety power supplies—giving engineers confidence that power won’t be the weak link in their safety systems. Additionally, its seamless integration with ABB’s safety ecosystem simplifies setup: it’s pre-configured to work with the ABB 3BHE023784R0001 and AC 800M HI controllers, eliminating the need for custom wiring or software tweaks and cutting commissioning time by 30%.

Application fields:

The ABB 3BHE024747R0101 is purpose-built for industries where safety system power failure is unacceptable, excelling in three key use cases. In nuclear power plants, it supplies redundant power to reactor safety systems—including coolant flow sensors and emergency shutdown controllers—ensuring power remains stable even during grid transients or internal component faults, critical for preventing core overheating. In oil and gas upstream operations (e.g., offshore drilling rigs), it powers safety loops for wellhead pressure monitoring and blowout preventer (BOP) controls, withstanding salt spray, vibration, and extreme temperatures to avoid well leaks or explosions. It’s also critical in chemical processing facilities, where it delivers power to toxic gas detection systems and emergency isolation valve controls—ensuring these safety components remain operational during power fluctuations common in plants with heavy electrical loads (e.g., from mixers or heaters). In each scenario, the ABB 3BHE024747R0101 meets the demands of SIL 3-critical uptime: its fast failover ensures no power gap to safety loops, while its diagnostics prevent unplanned failures that could leave facilities exposed.

Related products:

ABB 3BHE024747R0102 – Higher-power variant (200W total, 100W per path) for large SIS with multiple safety I/O modules.

ABB 3BHE024747R0103 – Lower-power model (50W total, 25W per path) for compact safety loops (e.g., small chemical tanks).

ABB 3BHE024747R0104 – DC-input variant (48V DC in, 24V DC out) for battery-backed safety systems (e.g., remote pipeline SIS).

ABB 3BHE024747R0105 – Extreme-temperature model (-30°C to 85°C) for desert oil fields or arctic mining safety systems.

ABB 3BHE024747R0101 + 3BHE024748R0101 – Bundle with power distribution module for feeding 8+ safety components.

ABB 3BHE024747R0106 – High-isolation variant (5kVrms input-output) for high-voltage SIS (e.g., power substation safety loops).

ABB 3BHE024747R0107 – Triple-redundant model (3x power paths) for SIL 3+ critical systems (e.g., nuclear reactor core cooling).

ABB 3BHE023784R0001 – Compatible safety I/O module, optimized for power matching with the ABB 3BHE024747R0101.

Installation and maintenance:

Before installing the ABB 3BHE024747R0101, first verify compatibility with your ABB safety system: it requires AC 800M HI v7.0+ or Advant OCS v6.5+, and older SIS firmware may need updates to support the module’s diagnostic communication. Next, calculate the total power load of connected safety components (e.g., I/O modules, controllers) to ensure it stays below the 100W max output—overloading can trigger protective shutdowns that disrupt safety loops. During setup, use ABB’s Safety Builder software to configure failover parameters: set threshold values for input voltage sags and output load limits to align with your facility’s safety requirements. Conduct a failover test by simulating a fault in one power path (e.g., disconnecting a rectifier) to confirm the module switches to the redundant path within 100ms—document this test for IEC 61508 compliance audits. For maintenance, perform weekly checks of the module’s LED status indicators: steady green lights confirm both power paths are active, while a amber light signals a non-critical fault (e.g., slight overheating) that requires investigation via Safety Builder. Every three months, inspect the backplane connectors for corrosion (common in humid or salt-rich environments) and torque terminals to ABB’s recommended 1.0 N·m to maintain reliable power delivery. Annual load testing, using a variable load bank to simulate peak SIS power demand, ensures the module’s output regulation (±0.3% tolerance) remains consistent over time.

Other ABB product models:

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB UAD155A0111 3BHE029110R0111

ABB 1TGE120040R0010

ABB DCF506-0140-51-0000000

ABB PCD530

ABB 1TGE120016R0104

ABB 1MRK000614-AB

ABB 5SHY35L4510

ABB PYT0450W071A

ABB DKTFM418B 3BHB015651P0001

ABB REF620E-1G NBFNAANNNEA1BNF11G

ABB PM858K02 3BSE082896R1

ABB PM902F 3BDH001000R0001

ABB KSD211B101 3BHE022455R1101

ABB PM863K02 3BSE088382R1

ABB SM812K01 3BSE072270R1

ABB UNS0867 HIEE405246R0002

ABB El3020 URAS26

ABB PM803F

ABB REF601BE446BD1NH

ABB 3BHE022287R0001

ABB PFTL101A-2.0KN 3BSE004172R1

ABB PTPU-02 3HNA023148-001

ABB UNITROL1020

ABB 3HAC028357-001

ABB 3BSE003832R1 SC510

ABB LM200

ABB SPAJ110C

ABB 1KHL178016R0001F

ABB 1KHL160038R0104D

ABB UP10C01000

ABB LD800HSE 3BDH000320R02

ABB 5SHY35L4520 5SXE10-0181

ABB VP01 2VAA008172R01

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626