Description

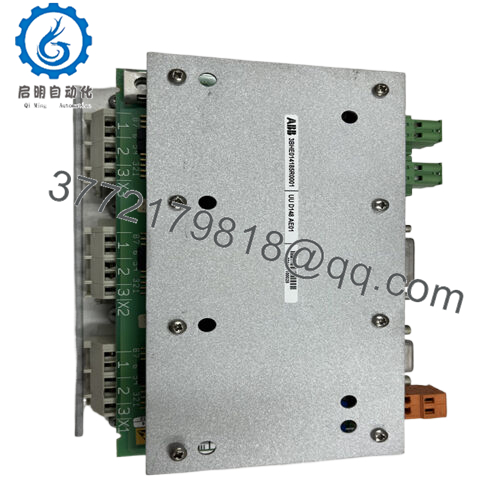

| Model Number | 3BHE014185R0001 UUD148AE01 |

| Brand | ABB |

| Type | Multi-Channel I/O Module (Analog/Digital) |

| Input/Output Channels | 8 configurable channels (4 analog in, 4 digital in/out) |

| Supported Signal Types | Analog: 4-20mA, 0-10V, RTD (PT100/PT1000), Thermocouple (K/J/T); Digital: 24V DC |

| Operating Temp Range | -10°C to 65°C (14°F to 149°F) |

| Mounting Style | ABB Control Cabinet Backplane (compatible with AC 800M/TCS enclosures) |

| Dimensions | 38mm (W) x 120mm (H) x 135mm (D) |

| Weight | 0.42kg (0.93lbs) |

| Interface/Bus | Profinet (ABB Proprietary Variant); Diagnostic Port (RS485) |

| Signal Conditioning | EMI Filtering (IEC 61000-6-2), Wiring Resistance Compensation |

| Compliance | CE, UL 508, IEC 61508 (SIL 2), RoHS, IEC 61131-2 |

| Supported Protocols | Profinet, ABB TCS Bus; Compatible with Control Builder M v7.0+ |

| Typical Power Draw | 3.8W (operating), 1.2W (standby) |

3BHE014185R0001 UUD148AE01

The ABB 3BHE014185R0001 UUD148AE01 acts as a critical interface layer in ABB’s automation stack, connecting field sensors (e.g., RTDs, thermocouples, 4-20mA transducers) to ABB control platforms like the AC 800M DCS or Turbine Control System (TCS). Unlike basic I/O modules, it supports both analog and digital signal types across 8 configurable channels—eliminating the need for multiple single-purpose modules and reducing cabinet space by up to 30%. It mounts directly to ABB’s standard control cabinet backplanes, communicating with the central controller via ABB’s proprietary Profinet-based bus protocol for low-latency data transmission (under 10ms).

3BHE014185R0001 UUD148AE01

A key advantage is its built-in signal conditioning: it filters electrical noise (per IEC 61000-6-2) and compensates for wiring resistance, ensuring sensor data remains accurate even in noisy environments (e.g., near turbine generators or VFDs). The module also includes advanced diagnostics: via ABB’s Control Builder M software, engineers can monitor channel health, detect open circuits or shorted sensors, and track module temperature—all in real time. By translating raw sensor data into actionable control signals, the ABB 3BHE014185R0001 UUD148AE01 forms the backbone of reliable data acquisition for ABB’s most demanding industrial systems.

Main features and advantages:

Choosing the ABB 3BHE014185R0001 UUD148AE01 delivers tangible operational value that goes beyond basic data acquisition. Its multi-channel flexibility reduces engineering overhead: instead of specifying, installing, and configuring separate analog and digital modules, engineers can program all 8 channels via software—cutting commissioning time by up to 40%. The module’s signal conditioning also eliminates the need for external filters or signal converters, reducing component count and potential failure points in the control system. For long-term reliability, its rugged design (including vibration resistance up to 3g peak, per IEC 60068-2-6) ensures consistent performance in harsh environments like power plant turbine halls or oil refinery process areas. This durability translates to a mean time between failures (MTBF) of over 200,000 hours—far longer than generic I/O modules—minimizing unplanned downtime. Additionally, its SIL 2 compliance simplifies safety certification for critical systems (e.g., turbine emergency shutdowns), as it meets the rigor of IEC 61508 without requiring additional safety layers. For engineers, this means fewer maintenance headaches, faster setup, and confidence that sensor data will drive accurate control decisions.

Application fields:

The ABB 3BHE014185R0001 UUD148AE01 excels in industries where precise, reliable data acquisition is non-negotiable, with three key use cases standing out. In power generation, it’s deployed in coal-fired, gas, and hydroelectric plants to collect data from turbine temperature sensors (RTDs/thermocouples) and pressure transducers—ensuring the AC 800M TCS receives accurate data to regulate turbine speed and prevent overheating. In oil and gas refining, it monitors process parameters like flow rate (4-20mA transducers) and valve position (digital signals) for crude distillation units, with its noise filtering capabilities blocking interference from nearby pumps and compressors. It’s also critical in chemical processing facilities, where it connects to level sensors and safety interlocks—supporting 24/7 batch production by ensuring the DCS receives real-time, error-free data to maintain process consistency. In each scenario, the ABB 3BHE014185R0001 UUD148AE01 meets the demands of critical system uptime: its low-latency data transmission ensures control systems respond quickly to changes, while its diagnostics prevent false alarms that would disrupt operations.

Related products:

ABB 3BHE014185R0002 UUD148AE02 – 16-channel variant for larger control systems (e.g., multi-turbine power plants).

ABB 3BHE014185R0003 UUD148AE03 – Analog-only module (8 channels) for sensor-heavy environments (e.g., temperature monitoring).

ABB 3BHE014185R0004 UUD148AE04 – Digital-only module (12 channels) for safety interlock systems (e.g., emergency stops).

ABB 3BHE014185R0005 UUD148AE05 – Extended-temperature variant (-25°C to 70°C) for offshore or cold-climate power plants.

ABB 3BHE014185R0006 UUD148AE06 – High-isolation model (2.5kVrms) for high-voltage substations or nuclear power applications.

ABB 3BHE014185R0001 UUD148AE01 + 3BHE014186R0001 – Bundle with signal termination module for faster wiring.

ABB 3BHE014185R0007 UUD148AE07 – Redundant I/O module for SIL 3 safety systems (e.g., turbine emergency shutdowns).

ABB 3BHE013299R0002 – Compatible power unit (80W) to supply stable power to the I/O module in turbine control setups.

Installation and maintenance:

Before installing the ABB 3BHE014185R0001 UUD148AE01, first verify compatibility with your ABB control system: it requires AC 800M DCS v6.1+ or TCS v7.0+, so older systems may need a firmware update to support its Profinet communication. Next, map out your sensor signal types (analog/digital) and channel requirements—using the module’s software-configurable channels to avoid overspecifying (e.g., assigning analog channels to digital sensors). During setup, use a calibrated signal generator to test each channel’s accuracy: for RTD inputs, confirm temperature readings match the generator’s setpoint within ±0.5°C; for 4-20mA signals, check that the module translates current to the correct engineering units (e.g., 12mA = 50% flow). For maintenance, conduct monthly checks of the module’s LED status: a steady green light indicates normal operation, while a yellow light signals a channel fault (use Control Builder M to identify the affected sensor). Every six months, inspect the backplane connector for corrosion (common in humid chemical plants) and torque terminals to ABB’s recommended 0.6 N·m—loose connections can cause signal dropouts. Annual functional testing, using a loop calibrator to simulate sensor inputs, ensures the module’s conditioning and transmission capabilities remain reliable.

Other ABB product models:

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB UAD155A0111 3BHE029110R0111

ABB 1TGE120040R0010

ABB DCF506-0140-51-0000000

ABB PCD530

ABB 1TGE120016R0104

ABB 1MRK000614-AB

ABB 5SHY35L4510

ABB PYT0450W071A

ABB DKTFM418B 3BHB015651P0001

ABB REF620E-1G NBFNAANNNEA1BNF11G

ABB PM858K02 3BSE082896R1

ABB PM902F 3BDH001000R0001

ABB KSD211B101 3BHE022455R1101

ABB PM863K02 3BSE088382R1

ABB SM812K01 3BSE072270R1

ABB UNS0867 HIEE405246R0002

ABB El3020 URAS26

ABB PM803F

ABB REF601BE446BD1NH

ABB 3BHE022287R0001

ABB PFTL101A-2.0KN 3BSE004172R1

ABB PTPU-02 3HNA023148-001

ABB UNITROL1020

ABB 3HAC028357-001

ABB 3BSE003832R1 SC510

ABB LM200

ABB SPAJ110C

ABB 1KHL178016R0001F

ABB 1KHL160038R0104D

ABB UP10C01000

ABB LD800HSE 3BDH000320R02

ABB 5SHY35L4520 5SXE10-0181

ABB VP01 2VAA008172R01

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626