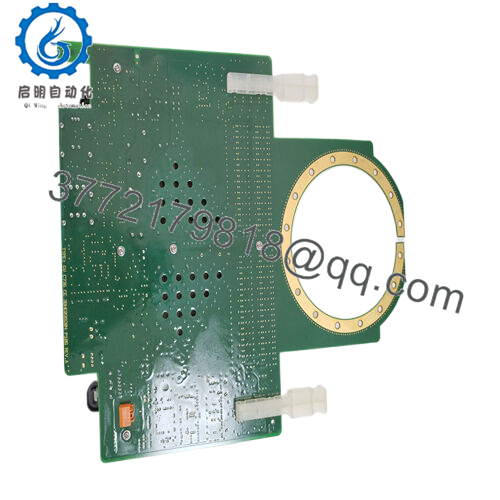

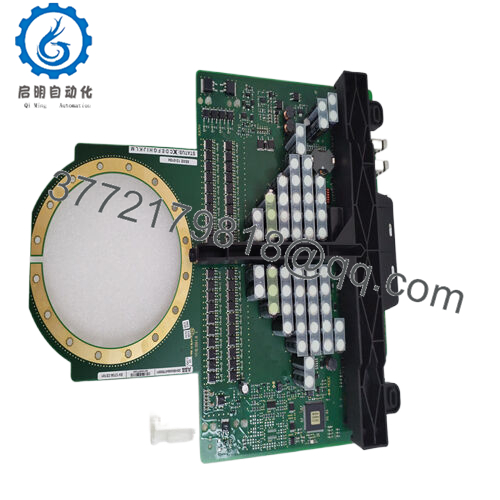

Description

| Model Number | 3BHB045647R0001 |

| Brand | ABB |

| Type | Regulated Industrial Power Supply Module |

| Input Voltage | 110/230V AC (auto-ranging) |

| Operating Temp Range | -10°C to 60°C (14°F to 140°F) |

| Mounting Style | DIN Rail (TS 35 standard) |

| Dimensions | 35mm (W) x 120mm (H) x 115mm (D) |

| Weight | 0.42kg (0.93lbs) |

| Interface/Bus | Terminal block (input/output); diagnostic signal via 4-20mA |

| Compliance | CE, UL 508, IEC 61010-1, RoHS |

| Supported Protocols | None (hardwired diagnostics); compatible with ABB Control Builder M |

| Typical Power Draw | 60W (max output), 5W (no-load standby) |

3BHB045647R0001

The ABB 3BHB045647R0001 operates as a foundational component in ABB’s automation stack, functioning as a regulated power supply that converts incoming AC line power to stable DC output for ABB control modules (e.g., AC 800M I/O modules, safety relays, or communication cards). It mounts directly to ABB’s standard DIN rail or control cabinet backplanes, drawing primary power (typically 110/230V AC) and delivering a consistent secondary output (24V DC) that meets the strict voltage tolerance requirements of ABB’s industrial electronics. Unlike generic power supplies, it includes built-in protection features—overvoltage, overcurrent, and short-circuit protection—that shield connected control components from damage during electrical anomalies.

3BHB045647R0001

The module also integrates with ABB’s diagnostic systems: via compatible DCS software (e.g., ABB Control Builder M), engineers can monitor real-time power output, track load levels, and receive alerts for potential issues (e.g., declining output voltage) before they impact operations. By sitting between the facility’s power grid and ABB’s control hardware, the ABB 3BHB045647R0001 ensures a reliable power chain, forming the backbone of stable industrial automation systems.

Main features and advantages:

Choosing the ABB 3BHB045647R0001 delivers tangible operational value that goes beyond basic power conversion. Engineered specifically for ABB’s control ecosystems, it eliminates the compatibility risks of using third-party power supplies—ensuring that voltage output, load capacity, and diagnostic communication align perfectly with ABB’s AC 800M DCS and related components. This seamless integration reduces commissioning time: engineers don’t need to modify wiring or configure custom workarounds, cutting setup hours by up to 30% compared to generic alternatives. The module’s rugged design—including a dust-resistant housing and wide operating temperature range—ensures consistent performance in harsh industrial settings, from the high humidity of paper mills to the electrical noise of steel plants. Over time, this durability translates to lower replacement costs: the ABB 3BHB045647R0001 has a mean time between failures (MTBF) of over 100,000 hours, minimizing unplanned downtime and reducing maintenance teams’ workload. Additionally, its built-in diagnostics enable predictive maintenance: by tracking output trends, engineers can replace the module proactively during scheduled shutdowns, avoiding emergency repairs that disrupt production.

Application fields:

The ABB 3BHB045647R0001 is deployed in industries where power reliability directly impacts safety, productivity, and compliance—making it a critical component in three key sectors. In power generation (coal, gas, or renewable plants), it supplies stable power to ABB’s turbine control systems and safety logic solvers, ensuring that critical parameters (e.g., turbine speed, steam pressure) are monitored without interruption. In chemical processing facilities, it powers ABB’s process analyzers and emergency shutdown (ESD) modules, withstanding corrosive atmospheres and voltage spikes to maintain compliance with safety standards like SIL 2. It’s also widely used in pulp and paper mills, where it delivers consistent power to ABB’s machine control modules—supporting 24/7 production cycles that require zero downtime for roll changes or quality checks. In each application, the ABB 3BHB045647R0001 meets the demands of critical system uptime: its regulated output prevents voltage drift that could corrupt sensor data, while its protection features shield expensive control hardware from electrical damage.

Related products:

ABB 3BHB045648R0001 – Higher-power variant (100W max output) for applications with heavier control system loads.

ABB 3BHB045646R0001 – Lower-power model (30W max output) for compact ABB control setups (e.g., small-scale DCS segments).

ABB 3BHB036488R0101 – Redundant power supply module for SIL 3 applications requiring fault-tolerant power.

ABB 3BHB045647R0002 – Extended-temperature version (-25°C to 70°C) for outdoor or extreme-environment control cabinets.

ABB 3BHB045647R0003 – Isolated output model for applications with high electrical noise (e.g., near large motors).

ABB 3BHB045649R0001 – DC-input variant (24V DC in, 24V DC out) for mobile or battery-backed control systems.

ABB 3BHB045647R0001 + 3BHB045650R0001 – Bundle with power distribution module for feeding multiple ABB control components.

Installation and maintenance:

Before installing the ABB 3BHB045647R0001, verify two key compatibility factors: first, confirm that your ABB control system (e.g., AC 800M) supports the module’s diagnostic signal—older DCS versions may require a firmware update to enable real-time power monitoring. Second, calculate the total load of connected components (e.g., I/O modules, relays) to ensure it does not exceed the module’s 60W max output; overloading can trigger protective shutdowns and damage the unit. During setup, use a multimeter to verify input voltage (110/230V AC) matches your facility’s power grid—incorrect input voltage is a common cause of early module failure. For ongoing maintenance, conduct monthly checks of the module’s LED status indicators: a steady green light confirms normal operation, while a flashing red light signals a fault (e.g., overcurrent, overheating). Every six months, inspect the input/output terminals for corrosion or loose wiring—especially in humid environments—and torque terminals to ABB’s recommended 0.8 N·m to prevent voltage drops. Annual load testing (using a variable load bank) ensures the module maintains regulated output under peak conditions.

Other ABB product models:

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB UAD155A0111 3BHE029110R0111

ABB 1TGE120040R0010

ABB DCF506-0140-51-0000000

ABB PCD530

ABB 1TGE120016R0104

ABB 1MRK000614-AB

ABB 5SHY35L4510

ABB PYT0450W071A

ABB DKTFM418B 3BHB015651P0001

ABB REF620E-1G NBFNAANNNEA1BNF11G

ABB PM858K02 3BSE082896R1

ABB PM902F 3BDH001000R0001

ABB KSD211B101 3BHE022455R1101

ABB PM863K02 3BSE088382R1

ABB SM812K01 3BSE072270R1

ABB UNS0867 HIEE405246R0002

ABB El3020 URAS26

ABB PM803F

ABB REF601BE446BD1NH

ABB 3BHE022287R0001

ABB PFTL101A-2.0KN 3BSE004172R1

ABB PTPU-02 3HNA023148-001

ABB UNITROL1020

ABB 3HAC028357-001

ABB 3BSE003832R1 SC510

ABB LM200

ABB SPAJ110C

ABB 1KHL178016R0001F

ABB 1KHL160038R0104D

ABB UP10C01000

ABB LD800HSE 3BDH000320R02

ABB 5SHY35L4520 5SXE10-0181

ABB VP01 2VAA008172R01

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626