Description

| Model Number | 3BHB017688R0001 |

| Brand | ABB |

| Type | High-Precision Analog I/O Module (AC 800M Compatible) |

| Input Voltage | 24 V DC (from AC 800M backplane) |

| Operating Temp Range | -10°C to 60°C (14°F to 140°F) |

| Mounting Style | AC 800M Backplane Mount (1-slot width) |

| Dimensions | 40 mm (W) x 125 mm (H) x 130 mm (D) |

| Weight | 260 g (0.57 lbs) |

| Interface/Bus | AC 800M Backplane Bus |

| Compliance | CE, UL 61010-1, IEC 61508 (SIL 2), RoHS |

| Supported Protocols | ABB Control Builder M, PROFINET (via AC 800M comm modules), Modbus RTU |

| Typical Power Draw | 2.1 W (from backplane) |

3BHB017688R0001

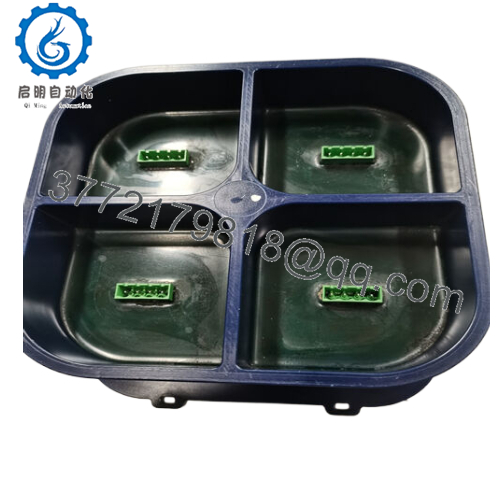

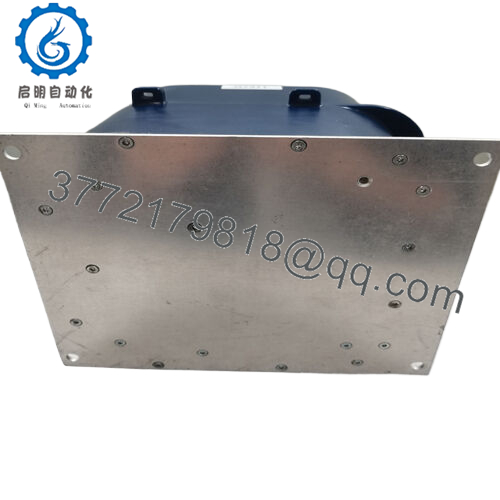

The ABB 3BHB017688R0001 functions as a high-precision analog I/O module in ABB’s industrial automation architecture, specifically engineered for integration with ABB AC 800M DCS and compatible control systems. It acts as a critical link between analog field sensors (e.g., RTDs, thermocouples, pressure transducers) and the central DCS: receiving analog input signals, converting them to digital data with 16-bit resolution, and transmitting validated data to the DCS for process control.

3BHB017688R0001

Unlike basic analog modules, the ABB 3BHB017688R0001 includes built-in signal conditioning—such as cold-junction compensation for thermocouples and noise filtering—to ensure measurement accuracy even in electrically noisy environments (e.g., near large motors or variable frequency drives). It also supports both analog input and output channels (8 inputs/4 outputs), enabling bidirectional communication: the DCS can send analog output commands (e.g., “adjust valve position”) to field actuators via the module, creating closed-loop control. The module connects to the AC 800M backplane, enabling synchronized data sharing with other system components (e.g., safety modules, HMIs) and supporting hot-swapping—engineers can replace the module without shutting down the DCS, minimizing maintenance-related downtime.

3BHB017688R0001

Main features and advantages:

Choosing the ABB 3BHB017688R0001 delivers measurable operational benefits that reduce risk and streamline engineering workflows. Its 16-bit resolution and ±0.05% full-scale accuracy ensure that precision-dependent processes—like pharmaceutical batch temperature control or petrochemical pressure monitoring—operate within tight tolerances, preventing costly errors such as out-of-spec products (which can lead to million-dollar recalls) or equipment overpressure. The module’s rugged design, rated for IP20 dust protection and resistance to vibration (up to 5 g), makes it suitable for harsh industrial environments, from chemical plants to food processing facilities, eliminating the need for specialized protective enclosures. Additionally, its native compatibility with ABB AC 800M DCS simplifies integration: engineers can configure the module using ABB’s Control Builder M software, avoiding the need for third-party signal conditioners or extensive retraining. Unlike generic analog modules, the ABB 3BHB017688R0001 is certified for SIL 2 safety compliance, making it ideal for semi-critical applications (e.g., process temperature monitoring in exothermic reactions) where measurement failures could impact operational safety.

Application fields:

The ABB 3BHB017688R0001 excels in industries where analog signal precision is mission-critical. In pharmaceutical manufacturing, it monitors the temperature of bioreactors using thermocouple inputs, ensuring ±0.1°C accuracy to maintain cell viability and comply with FDA regulations—critical for producing life-saving drugs. In petrochemical refining, it processes pressure signals from pipeline transducers, enabling the DCS to adjust valve positions in real time and prevent overpressurization (a risk that could lead to explosions or environmental spills). It’s also widely used in food and beverage production, where it monitors flow rates of ingredients (e.g., syrup in soda manufacturing) via analog inputs, ensuring consistent product formulation and reducing waste. In each of these use cases, the ABB 3BHB017688R0001 delivers the accuracy, reliability, and flexibility needed to maintain operational continuity, while its combined input/output channels reduce the number of modules required—saving backplane space and lowering overall system costs.

Related products:

ABB 3BHB017688R0002 – Higher-channel variant (16 inputs/8 outputs) for large-scale precision control systems (e.g., multi-reactor pharmaceutical plants).

ABB 3BHB017689R0001 – Input-only analog module (12 inputs); ideal for applications requiring more sensing points than output commands.

ABB 3BHB017690R0001 – Isolated analog I/O module; offers 2.5 kV AC galvanic isolation for high-noise environments (e.g., steel mills).

ABB 3BHB005243R0105 – Power supply module; compatible with ABB 3BHB017688R0001 to ensure stable backplane power delivery.

ABB 3BHB017691R0001 – High-temperature variant (-20°C to 70°C); suitable for extreme environment applications (e.g., desert-based solar thermal plants).

Installation and maintenance:

Before installing the ABB 3BHB017688R0001, verify that the AC 800M backplane has an available slot and that the DCS firmware is updated to version 6.0 or later—older firmware may not support the module’s 16-bit resolution or signal conditioning features. Check that field sensor wiring is rated for analog signals (e.g., twisted-pair cables for noise reduction) and that wiring distances do not exceed 200 meters (to avoid signal attenuation). During installation, ensure the module is seated firmly in the backplane to maintain a reliable bus connection; loose connections can cause intermittent data dropouts. For ongoing maintenance, review DCS diagnostic logs weekly to monitor module temperature, input/output signal levels, and calibration status—address any anomalies (e.g., signal drift beyond ±0.05% full scale) immediately. Every 2 years, perform a calibration check using ABB’s calibration software and certified test equipment to ensure the module maintains its rated accuracy, critical for meeting regulatory requirements (e.g., FDA 21 CFR Part 11).

Other ABB product models:

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB UAD155A0111 3BHE029110R0111

ABB 1TGE120040R0010

ABB DCF506-0140-51-0000000

ABB PCD530

ABB 1TGE120016R0104

ABB 1MRK000614-AB

ABB 5SHY35L4510

ABB PYT0450W071A

ABB DKTFM418B 3BHB015651P0001

ABB REF620E-1G NBFNAANNNEA1BNF11G

ABB PM858K02 3BSE082896R1

ABB PM902F 3BDH001000R0001

ABB KSD211B101 3BHE022455R1101

ABB PM863K02 3BSE088382R1

ABB SM812K01 3BSE072270R1

ABB UNS0867 HIEE405246R0002

ABB El3020 URAS26

ABB PM803F

ABB REF601BE446BD1NH

ABB 3BHE022287R0001

ABB PFTL101A-2.0KN 3BSE004172R1

ABB PTPU-02 3HNA023148-001

ABB UNITROL1020

ABB 3HAC028357-001

ABB 3BSE003832R1 SC510

ABB LM200

ABB SPAJ110C

ABB 1KHL178016R0001F

ABB 1KHL160038R0104D

ABB UP10C01000

ABB LD800HSE 3BDH000320R02

ABB 5SHY35L4520 5SXE10-0181

ABB VP01 2VAA008172R01

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626