Description

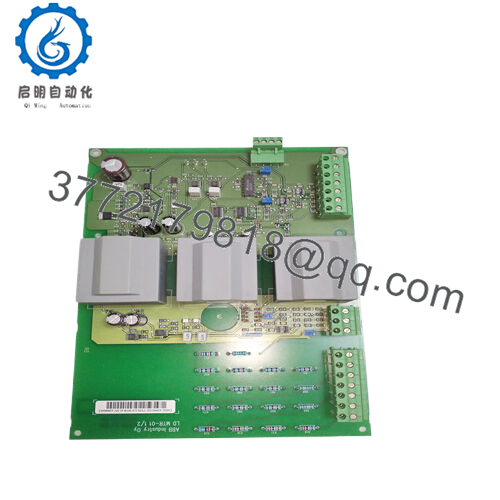

| Model Number | 3BHB007445P0001 |

| Brand | ABB |

| Type | Regulated Industrial Power Supply Module (AC 800PEC Compatible) |

| Input Voltage | 100–240 V AC (50/60 Hz) |

| Operating Temp Range | -15°C to 70°C (5°F to 158°F) |

| Mounting Style | DIN Rail Mount (35 mm standard) |

| Dimensions | 95 mm (W) x 130 mm (H) x 145 mm (D) |

| Weight | 920 g (2.03 lbs) |

| Interface/Bus | ABB Backplane Bus (for diagnostics) |

| Compliance | CE, UL 508, IEC 61010-1, RoHS |

| Supported Protocols | Integrates with ABB Control Builder M (for configuration) |

| Typical Power Draw | 65 W (max output: 24 V DC @ 2.7 A) |

3BHB007445P0001

The ABB 3BHB007445P0001 operates as a rugged, regulated power supply module in ABB’s industrial control architecture, specifically engineered for integration with ABB AC 800PEC and compatible process control systems. It converts a wide-range AC input (100–240 V AC) into a stable 24 V DC output— the industry standard for powering control components—while incorporating advanced filtering to suppress electrical noise from nearby machinery (a common issue in factory floors or power plants).

3BHB007445P0001

Unlike generic power supplies, the ABB 3BHB007445P0001 supports parallel redundancy: pairing two modules creates a 1+1 backup setup, ensuring power delivery continues uninterrupted if one module fails—critical for systems where even a second of downtime risks safety or revenue loss. The module also includes real-time diagnostic features, such as overcurrent protection and thermal overload monitoring, which transmit status data to the central DCS. This allows engineers to proactively address issues (like a failing internal fan or excessive load) before they cause system disruptions, reducing the need for manual inspections. It connects to the control system via ABB’s proprietary backplane bus, enabling synchronized power monitoring and configuration through ABB’s Control Builder M software.

Main features and advantages:

Choosing the ABB 3BHB007445P0001 delivers tangible operational value that reduces long-term risk and engineering overhead. Its tight voltage regulation (±0.3% of nominal 24 V DC) ensures connected control components—like safety I/O modules or turbine control drivers—receive consistent power, preventing data corruption or component damage caused by voltage instability. The module’s rugged design, rated for IP20 dust protection and resistance to vibration (up to 5 g) and shock (up to 15 g), makes it suitable for harsh environments, from offshore oil rigs to steel mills, eliminating the need for expensive climate-controlled enclosures. Additionally, its native compatibility with ABB AC 800PEC systems simplifies integration: engineers can drop the module into existing setups without modifying wiring or using third-party adapters, cutting installation time by up to 40% compared to non-ABB alternatives. Unlike generic power supplies, the ABB 3BHB007445P0001 is validated to work with ABB’s safety-certified components, helping systems meet strict industry standards like IEC 61508 (SIL 2) for functional safety—critical for applications where failures could harm personnel or the environment.

Application fields:

The ABB 3BHB007445P0001 excels in industries where uninterrupted power to control systems is mission-critical. In chemical processing plants, it powers ABB AC 800PEC modules that monitor reactor pressure and chemical flow, ensuring emergency shutdown systems activate reliably if parameters exceed safe limits. In power generation facilities, it supplies power to turbine control units and grid synchronization modules, preventing costly downtime (which can exceed $100,000 per hour for fossil fuel plants) caused by power interruptions. It’s also widely used in wastewater treatment plants, where it powers control systems for pumps and chemical dosing units—ensuring consistent treatment processes to meet environmental regulations. In each of these use cases, the ABB 3BHB007445P0001 delivers the reliability and stability needed to avoid operational disruptions, while its diagnostic features reduce maintenance time by enabling remote issue identification.

Related products:

ABB 3BHB007445P0002 – Higher-output variant (24 V DC @ 4.2 A) for systems with more connected control components.

ABB 3BHB006545R0001 – Redundancy controller module; optimizes parallel redundancy for two ABB 3BHB007445P0001 units.

ABB 3BHB005243R0105 – Lower-power sibling (24 V DC @ 2.1 A) for smaller AC 800PEC setups.

ABB 3BHB007446P0001 – Wide-temperature variant (-40°C to 75°C) for extreme cold environments (e.g., arctic pipelines).

ABB 3BHB008123R0001 – Isolated power supply module; offers 2.5 kV AC galvanic isolation for high-noise industrial settings.

Schneider Electric ABL8REM24060 – Third-party alternative; DIN rail mount but requires adapter for ABB diagnostic integration.

Siemens SITOP PSU300M 6EP1436-3BA10 – Competitor module; similar output but limited compatibility with ABB AC 800PEC.

Installation and maintenance:

Before installing the ABB 3BHB007445P0001, verify that the target DIN rail can support the module’s 920 g weight and that the input power circuit includes a 16 A circuit breaker (to protect against overcurrent). Check that the AC 800PEC system firmware is updated to version 6.0 or later—older firmware may not recognize the module’s advanced diagnostic features. During installation, ensure the module is mounted at least 30 mm away from heat-generating components (like variable frequency drives) to maintain its -15°C to 70°C operating range; insufficient airflow can lead to thermal shutdown. For ongoing maintenance, review DCS diagnostic logs monthly to monitor output voltage, temperature, and load percentage—address any deviations from nominal values immediately. Replace the module’s internal cooling fan every 4 years (or sooner if abnormal noise is detected) to prevent overheating. every year,perform a load test using a 24 V DC dummy load (2.7 A max) to confirm voltage regulation remains within ±0.3% of nominal.

Other ABB product models:

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB UAD155A0111 3BHE029110R0111

ABB 1TGE120040R0010

ABB DCF506-0140-51-0000000

ABB PCD530

ABB 1TGE120016R0104

ABB 1MRK000614-AB

ABB 5SHY35L4510

ABB PYT0450W071A

ABB DKTFM418B 3BHB015651P0001

ABB REF620E-1G NBFNAANNNEA1BNF11G

ABB PM858K02 3BSE082896R1

ABB PM902F 3BDH001000R0001

ABB KSD211B101 3BHE022455R1101

ABB PM863K02 3BSE088382R1

ABB SM812K01 3BSE072270R1

ABB UNS0867 HIEE405246R0002

ABB El3020 URAS26

ABB PM803F

ABB REF601BE446BD1NH

ABB 3BHE022287R0001

ABB PFTL101A-2.0KN 3BSE004172R1

ABB PTPU-02 3HNA023148-001

ABB UNITROL1020

ABB 3HAC028357-001

ABB 3BSE003832R1 SC510

ABB LM200

ABB SPAJ110C

ABB 1KHL178016R0001F

ABB 1KHL160038R0104D

ABB UP10C01000

ABB LD800HSE 3BDH000320R02

ABB 5SHY35L4520 5SXE10-0181

ABB VP01 2VAA008172R01

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626