Description

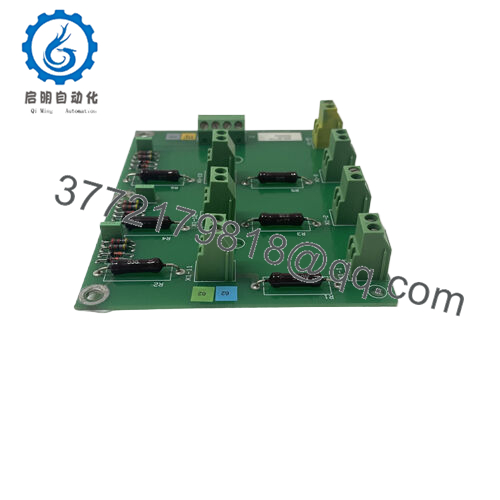

Product Model: ABB 3ASC25H215E DATX131

Product Brand: ABB

Product Series: ABB Distributed Control / DCS Systems

Product Features:

- High-performance processor module for ABB distributed control applications

- Ensures precise execution of real-time control strategies

- Hot-swappable design reduces plant downtime during maintenance

- Compatible with ABB DCS and legacy systems for flexible integration

Applications & Industry Context

The ABB 3ASC25H215E DATX131 is a critical processor module in ABB’s distributed control systems, providing real-time processing and control for industrial plants. Its robustness and reliability make it ideal for oil & gas refineries, chemical manufacturing, power generation, and pulp & paper operations.

For example, in a refinery, the module manages control loops for distillation columns, pressure vessels, and heat exchangers. Any delay or fault could compromise safety and product quality. The DATX131 guarantees deterministic execution of process control strategies, maintaining system stability even under fluctuating operating conditions.

In power plants, it monitors turbine performance, boiler operations, and emission control systems. Similarly, in chemical plants, it ensures precise chemical dosing, reaction control, and quality compliance. Water treatment facilities benefit from continuous monitoring and control of pumps, valves, and chemical dosing systems.

The ABB 3ASC25H215E DATX131 is also valued in legacy installations, offering compatibility that allows plants to extend the operational life of existing ABB DCS systems while upgrading to modern performance standards.

- 3ASC25H215E DATX131

- 3ASC25H215E DATX131

Product Role & System Fit

Within the ABB DCS architecture, the 3ASC25H215E DATX131 functions as the central processing unit that executes the control logic. Field I/O modules feed the system with sensor and instrument data, while operator workstations visualize processes. The DATX131 interprets the input, executes control algorithms, and issues commands to actuators and other modules.

Its modular, rack-based design enables easy integration with existing ABB systems. Hot-swappable functionality allows engineers to replace the module without shutting down the system, while redundancy configurations provide failover capabilities for uninterrupted plant operation.

Compatibility with legacy ABB hardware is a major benefit for plants, reducing the need for system redesign or expensive migration, while allowing upgrades in performance and reliability.

Technical Features & Benefits

The ABB 3ASC25H215E DATX131 provides multiple advantages that make it indispensable in industrial automation:

- Real-Time Processing: Executes control loops deterministically, ensuring accurate process regulation.

- Redundancy Support: Supports hot standby configurations for failover protection.

- Hot-Swappable Module: Replacement or upgrades can occur without system downtime.

- Integrated Diagnostics: Self-monitoring and fault reporting reduce troubleshooting time.

- Rugged Design: Built to withstand harsh industrial environments including electrical noise and temperature variations.

- Lifecycle Support: ABB provides long-term availability of parts, upgrades, and technical assistance.

These features contribute to reduced operational risks, optimized uptime, and lower total cost of ownership for plant operators.

Technical Specifications Table

| Specification | Details |

|---|---|

| Product Model | ABB 3ASC25H215E DATX131 |

| Brand | ABB |

| Series | Distributed Control System (DCS) |

| Module Type | Processor / Control Module |

| Processing Function | Real-time execution of control logic |

| Communication | ABB DCS network protocols |

| Redundancy Support | Yes – hot standby supported |

| Hot-Swappable | Yes |

| Diagnostics | Built-in self-checking and reporting |

| Operating Temperature Range | -20 °C to +70 °C |

| Mounting | Rack-based installation |

| Applications | Oil & gas, chemical, power, pulp & paper, water treatment |

Installation & Maintenance Insights

Installing the ABB 3ASC25H215E DATX131 is straightforward with ABB’s rack system. Keyed connectors ensure correct placement, and the system automatically recognizes the module upon insertion.

Maintenance teams benefit from hot-swappable functionality, allowing module replacement without plant downtime. Built-in diagnostics provide precise error codes to identify faulty channels or performance issues quickly.

Regular checks include verifying secure module seating, ensuring proper cabinet airflow and cooling, and validating redundancy synchronization. Following these best practices ensures long-term reliability and stable system operation.

Related Models

- ABB 086348-001 – ABB Bailey INFI 90 control processor module

- ABB UAD149A0001 3BHE014135R0001 – Control module for Bailey and Symphony DCS

- ABB IMMFP12 – Multi-function processor for INFI 90 systems

- ABB INICT03A – Network interface module for ABB DCS

- ABB INNIS01 – System interface unit for INFI 90 networks

- ABB 3BSE025833R1 – DCS processor module with extended capabilities

- ABB 3BHE010111R1 – Legacy control board for process automation

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626