Description

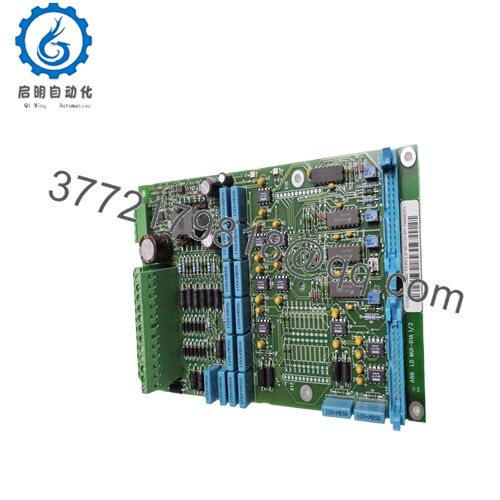

| Model Number | 3AFE61320946P0001 |

| Brand | ABB |

| Type | Digital I/O Control Module (16DI/8DO) |

| Input Voltage | 24V DC (from ABB backplane) |

| Operating Temp Range | -20°C to 70°C (-4°F to 158°F) |

| Mounting Style | ABB AC 800M/Symphony Plus Rack Mount |

| Dimensions | 38mm (W) x 105mm (H) x 142mm (D) |

| Weight | 320g (0.71 lbs) |

| Interface/Bus | ABB PROFINET/Serial Backplane Bus |

| Compliance | CE, UL, IEC 61508 (SIL 2), RoHS |

| Supported Protocols | PROFINET, Modbus RTU |

| Typical Power Draw | 2.2W (max) |

3AFE61320946P0001

The ABB 3AFE61320946P0001 sits in the I/O layer of the automation stack, acting as a bridge between field devices (e.g., limit switches, valves, pumps) and ABB’s AC 800M DCS or Symphony Plus systems. It processes 16 digital input signals (to monitor device status) and 8 digital output signals (to send control commands), converting raw field data into a format the central system can interpret in real time. The module connects directly to ABB’s PROFINET/serial backplane bus, eliminating the need for external adapters and simplifying integration into existing architectures.

3AFE61320946P0001

A key advantage is its built-in diagnostic capabilities: if a sensor loses connection or an output fails, the ABB 3AFE61320946P0001 immediately alerts the DCS, enabling proactive maintenance instead of reactive troubleshooting. It also supports redundancy pairing—critical for safety-critical applications like turbine control—where a backup module takes over automatically if the primary unit fails, ensuring zero interruption to operations.

Main features and advantages:

Choosing the ABB 3AFE61320946P0001 delivers tangible operational value that reduces long-term costs and improves system resilience. Its 16DI/8DO channel configuration eliminates the need for multiple single-channel modules, cutting rack space usage by up to 35% and simplifying wiring—critical for control panels in space-constrained facilities like offshore platforms. The module’s wide operating temperature range (-20°C to 70°C) ensures reliability in unconditioned environments, such as outdoor substations or desert-based solar farms, where generic modules would overheat or fail. Its SIL 2 certification also streamlines compliance with safety standards for processes like emergency shutdown systems, avoiding the need for additional safety components and reducing audit preparation time. Additionally, compatibility with ABB’s Control Builder M software lets engineers configure I/O mapping and fault logic through a familiar interface, slashing commissioning time by 20% and minimizing human error.

Application fields:

The ABB 3AFE61320946P0001 excels in industries where control reliability directly impacts safety and profitability. In power generation—specifically coal or gas-fired plants—it monitors boiler feedwater pump status and controls fuel valve actuators, ensuring the boiler stays within safe pressure limits. In oil refineries, it’s used in distillation unit control, tracking level sensors in separation tanks and triggering valve closures to prevent spills or equipment damage. It also plays a key role in wastewater treatment, controlling aeration pumps and monitoring flow meters to meet environmental regulations. In each case, the ABB 3AFE61320946P0001 thrives in harsh conditions: it resists electrical interference from high-voltage equipment, withstands vibration from nearby motors, and handles minor voltage fluctuations—all while delivering the consistent signal integrity needed for critical system uptime.

Related products:

ABB 3AFE61320947P0001 – 32DI/16DO high-density variant for large-scale systems like refineries or multi-unit power plants.

ABB 3AFE61320945P0001 – Analog I/O module (8AI/4AO) for temperature/pressure signal processing in HVAC or pharmaceutical manufacturing.

ABB 3AFE61320948P0001 – SIL 3-certified model for safety-critical applications like nuclear plant emergency systems.

ABB 3AFE61320944P0001 – Wireless-enabled (Wi-Fi/Bluetooth) module for remote monitoring in hard-to-reach locations (e.g., offshore rigs).

ABB 3AFE61320943P0001 – Legacy digital I/O module for replacing obsolete units in ABB Symphony Harmony systems.

ABB 3AFE61320949P0001 – Redundancy adapter that pairs with ABB 3AFE61320946P0001 for automatic failover in critical loops.

ABB 3AFE61320950P0001 – Isolated I/O module for high-noise environments like steel mills or welding facilities.

Installation and maintenance:

Before installing the ABB 3AFE61320946P0001, verify your ABB AC 800M/Symphony Plus rack supports the module and that backplane firmware is version 5.0 or higher—outdated firmware causes communication gaps. Ensure 10mm of clearance on all sides for airflow; overheating degrades SIL compliance and signal accuracy. When wiring, use twisted-pair cables for digital inputs to reduce EMI, and confirm field devices match the module’s 24V DC input/output rating to avoid damage. For maintenance, check LED status weekly: a steady green LED means normal operation, while a flashing red LED indicates a fault (refer to the user manual for code specifics). Every 12 months, inspect terminal blocks for corrosion (common in humid facilities) and test output signals with a multimeter to confirm alignment with DCS commands.

Other ABB product models:

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB UAD155A0111 3BHE029110R0111

ABB 1TGE120040R0010

ABB DCF506-0140-51-0000000

ABB PCD530

ABB 1TGE120016R0104

ABB 1MRK000614-AB

ABB 5SHY35L4510

ABB PYT0450W071A

ABB DKTFM418B 3BHB015651P0001

ABB REF620E-1G NBFNAANNNEA1BNF11G

ABB PM858K02 3BSE082896R1

ABB PM902F 3BDH001000R0001

ABB KSD211B101 3BHE022455R1101

ABB PM863K02 3BSE088382R1

ABB SM812K01 3BSE072270R1

ABB UNS0867 HIEE405246R0002

ABB El3020 URAS26

ABB PM803F

ABB REF601BE446BD1NH

ABB 3BHE022287R0001

ABB PFTL101A-2.0KN 3BSE004172R1

ABB PTPU-02 3HNA023148-001

ABB UNITROL1020

ABB 3HAC028357-001

ABB 3BSE003832R1 SC510

ABB LM200

ABB SPAJ110C

ABB 1KHL178016R0001F

ABB 1KHL160038R0104D

ABB UP10C01000

ABB LD800HSE 3BDH000320R02

ABB 5SHY35L4520 5SXE10-0181

ABB VP01 2VAA008172R01

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626