Description

In industrial automation, where the heartbeat of your process control system relies on instantaneous, error-free execution of protection algorithms, engineers frequently face the specter of delayed responses or corrupted data streams that can escalate minor anomalies into major outages. Envision a substation where transformer currents surge unpredictably, and your relay setup falters due to sluggish signal evaluation—resulting in tripped breakers that cascade across the grid, racking up downtime costs and regulatory scrutiny. Or consider a pulp mill’s drive controls, amid relentless humidity and electrical noise, where imprecise processing of digitized measurements leads to motor overloads, compromising throughput and equipment integrity. These pressures underscore a fundamental requirement: a processing core that delivers unwavering real-time analysis and decision-making, fortifying high reliability in I/O signal chains without the drag of frequent recalibrations or hardware swaps.

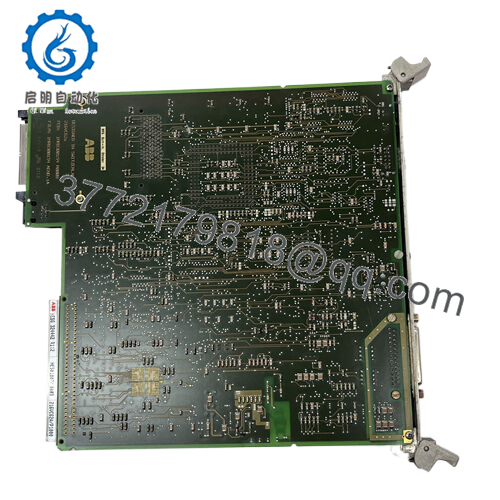

This is the domain the ABB 216VC62a-P1000 HESG324442R112 commands as a sophisticated processor unit board, integral to ABB’s legacy Procontrol and Advant architectures for robust protection and control. It zeroes in on the engineer’s aim for seamless algorithm deployment and data integrity, continuously benchmarking digitized inputs against setpoints to trigger safeguards like trip signals or interlocks with unerring precision. In high-stakes scenarios—such as generator synchronization in utilities or fault detection in drive systems—the ABB 216VC62a-P1000 HESG324442R112 emerges as critical, offloading complex computations from the main bus to maintain loop stability. Its emphasis on modular interfacing means you bypass the tedium of bespoke middleware, channeling clean outputs to downstream units for actions that prevent escalation, all while aligning with the high reliability mandates of SIL-rated environments.

216VC62a-P1000 HESG324442R112

216VC62a-P1000 HESG324442R112

The ABB 216VC62a-P1000 HESG324442R112 stands out in industrial automation for its pragmatic edge in handling the chaos of live operations, where it doesn’t just process but anticipates, assigning external interlocks or pickup events via configurable software to avert false positives that erode confidence. For those modernizing older DCS footprints, it streamlines the handoff from analog-era relics to digital oversight, ensuring I/O signals propagate without latency that could mask evolving faults. Ultimately, it equips you to sustain process control that’s not merely reactive but prescient, trimming the margins where vulnerabilities lurk and bolstering the uptime your operations bank on.

The ABB 216VC62a-P1000 HESG324442R112 anchors the computational layer in your automation hierarchy, embedded within protection relay assemblies or PLC backplanes to dissect incoming digitized variables—currents, voltages, or positions—from primary transducers. It runs bespoke firmware that compares these against protection thresholds, firing outputs via the internal B448C bus to I/O companions like the 216AB61 for tripping relays or the 216DB61 for status logging, all while weaving in external signals from field contacts for nuanced logic. In a Procontrol rack, it slots into a dedicated carrier, sharing the bus for synchronized polling that keeps cycle times under 10ms, ideal for time-critical sequences.

Engagement with peripherals is straightforward yet potent: it decodes HART overlays or basic serial protocols for sensor fusion, with galvanic isolation to quarantine noise from upstream feeders. Diagnostics embed deeply, relaying fault histograms or setpoint drifts to supervisory tools for preemptive tweaks, and its hot-plug design lets you refresh it during light-load windows without full-system halts. Nestled in the mid-stack—above field terminations but below SCADA abstraction—the ABB 216VC62a-P1000 HESG324442R112 facilitates distributed intelligence, scaling from single-relay guardians to networked clusters in 800xA extensions. For transitional setups blending ABB classics with Ethernet backbones, its protocol agility curtails gateway sprawl, letting you hone control strategies rather than debug handshakes.

| Specification | Details |

|---|---|

| Model Number | 216VC62a-P1000 HESG324442R112 |

| Brand | ABB |

| Type | Processor Unit Board |

| Input Voltage | 24 V DC |

| Operating Temp Range | -10°C to +55°C |

| Mounting Style | Rack / Backplane |

| Dimensions | 250 x 150 x 50 mm |

| Weight | 1.0 kg |

| Interface/Bus | B448C Internal Bus |

| Compliance | CE, RoHS, IEC 61508 (SIL 2) |

| Supported Protocols | Modbus RTU, Serial ASCII |

| Typical Power Draw | 6 W |

Deploying the ABB 216VC62a-P1000 HESG324442R112 instills a reliability quotient that’s calibrated for the relentless pulse of protective duties, where its fortified logic core sustains flawless setpoint evaluations through EMI barrages or thermal flux, yielding the performance consistency that averts nuisance trips and their downstream tolls. In relay chains exposed to arc flashes or harmonic distortions, this translates to steadfast signal fidelity, empowering operators to trust their dashboards without the overhang of validation scrambles—directly feeding into safer, leaner shifts with reduced event logs.

Integration unfolds with a consultative finesse, paring engineering overhead by auto-mapping bus allocations in ABB’s configuration suite; layer on a new input stage, and it’s validating thresholds in a session, not a sprint, while self-auditing routines surface setpoint variances for drift-free longevity. Engineered for the tenure of legacy-modern hybrids, the ABB 216VC62a-P1000 HESG324442R112 cultivates maintenance efficiency through embedded traces that forecast overloads, elongating service windows and curtailing the cycle of tear-downs that sideline production. In the broader arc, it nurtures an automation fabric resilient to expansions, where adding protection zones amplifies coverage without eroding core responsiveness, securing long-term performance that aligns with capex prudence and opex agility.

Power sector engineers turn to the ABB 216VC62a-P1000 HESG324442R112 for transformer differential relays, where it crunches current vectors in real time to detect windings faults amid grid volatility—its rapid bus dispatches ensure trip precision, upholding critical system uptime in process control environments that brook no delays for blackout prevention. In marine propulsion controls, it governs motor protections against torque spikes from wave-induced loads; here, vibration-hardened processing maintains high reliability, interfacing with shaft encoders for seamless synchronization in harsh, salt-laced settings.

Cement plants harness it in kiln drive safeguards, evaluating speed discrepancies to interlock during clinker burns—fast data cycles filter thermal noise, integrating into DCS for oversight that sustains continuous uptime without thermal runaway risks. Spanning utilities, offshore ops, and heavy process—the ABB 216VC62a-P1000 HESG324442R112 fortifies deployments craving unyielding vigilance and adaptive industrial automation.

216VC62a HESG324442R13 – Refined revision for elevated throughput in denser protection schemes.

216DB61 HESG324015R100 – Input companion module for external signal ingestion in relay logic.

216AB61 HESG324017R100 – Output relay unit, tailored for trip command routing from processor cues.

GVC736CE01 3BHB006980R0101 – Gate drive interface add-on for motor control extensions.

216NG63A HESG324444R100 – Auxiliary processing board for parallel algorithm offloads.

DAPU100 3ASC25H204 – Power unit variant for stable excitation in protection stacks.

DATX131 3ASC25H215E – Feedback processor alternative for resolver-based inputs.

Prior to seating the ABB 216VC62a-P1000 HESG324442R112 in its carrier, audit the B448C bus integrity with a continuity probe—loose terminations here can seed intermittent dropouts, so spec-check against the rack diagram from ABB’s archive. Assess cabinet humidity too; above 80% RH without dehumidifiers risks condensation on the board edges, so integrate silica packs if your locale swings damp—pair that with a firmware snapshot to baseline against the latest patch, running a dry simulation of pickup logic to flag config clashes. Grounding loops warrant a once-over as well; stray potentials amplify noise, so loop a milliohmmeter across chassis ties.

With it operational, maintenance adopts a rhythm of informed checks over blanket overhauls. Fortnightly scans of the status ports via serial link can unearth cycle elongations, triggering a targeted bus sweep for capacitance creeps. Biannually, demount for connector audits—clean with isopropyl if oxidation hints emerge, and re-torque to 0.6 Nm to defy settling from operational hums. Anchor an annual deep dive with software exports: replay fault scenarios, recalibrate setpoints if variance tops 0.5%, and log for trend spotting like gradual RAM wear. In EMI-saturated zones, shield inspections every quarter fortify against ingress, but keep it light—these protocols tap the unit’s innate reporting to preserve your process control’s edge without undue wrench time.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626