Description

In the high-stakes arena of industrial automation, where the execution of complex protection algorithms must occur with unerring speed to avert faults that could cascade into widespread disruptions, engineers often grapple with the limitations of sluggish processing, fragmented diagnostics, or rigid architectures that compromise real-time responsiveness. Envision a substation where generator synchronization demands instantaneous evaluation of current imbalances—any processing lag could trigger unwarranted trips, destabilizing the grid and racking up millions in lost generation or repair costs. Or picture a marine propulsion control system, enduring relentless vibration and electromagnetic noise, where imprecise signal analysis delays torque vectoring, risking shaft misalignment or fuel inefficiencies in missions where every nautical mile ties to operational viability. These scenarios aren’t anomalies; they’re the routine reckonings in process control environments, where high reliability in I/O signal processing is paramount to sustaining loop stability without the constant shadow of false positives or scalability ceilings.

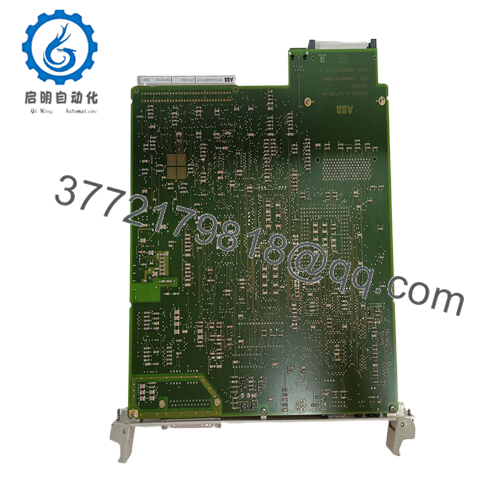

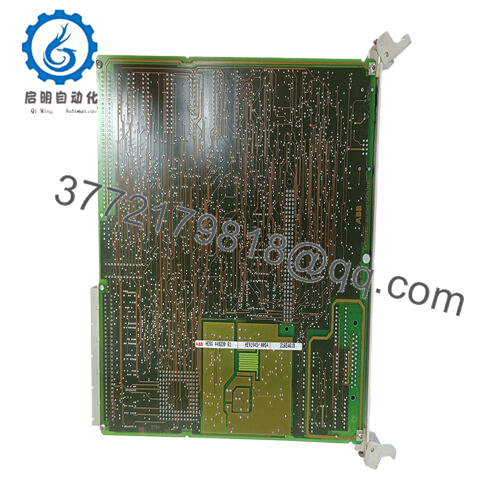

The ABB 216VC62A enters as a high-performance processor unit board in ABB’s Procontrol P3 series, engineered for the core computational demands of protection and control relays in power and industrial systems. It targets the engineer’s pursuit of rapid, deterministic execution, leveraging a 32-bit RISC processor with 256 MB RAM to crunch digitized inputs—voltages, currents, or binary states—against configurable thresholds, outputting trip commands or interlocks via integrated buses with cycle times under 10 ms. In critical deployments like transformer differential relays or motor protection schemes, the ABB 216VC62A proves essential, its modular slot design accommodating up to 10,000 I/O points through S800 expansions, while supporting IEC 61131-3 languages like Ladder Diagram for seamless logic deployment. By embedding self-supervision for memory checksums and fault logging, it minimizes diagnostic downtime, ensuring I/O signals feed accurate process control that adapts to transients without reconfiguration overloads.

What elevates the ABB 216VC62A in industrial automation is its poised performance in legacy-modern hybrids—it’s the board that doesn’t just compute but contextualizes, with RS-423 serial interfaces for configuration and event buffering that unravels upset sequences for forensic refinement. For outfits sustaining Procontrol footprints amid shifts to 800xA, it eases the bridge from analog-era relays to digital oversight, upholding high reliability that meets SIL 2 standards without proprietary pitfalls. Ultimately, it empowers process control that’s vigilant and versatile, curbing the variances that vex uptime and aligning with the precision your safety protocols and yield imperatives require.

The ABB 216VC62A anchors the processing heart in your relay or DCS stack, docking into Procontrol carriers to ingest sampled data from A/D converters like the 216EA61 via the internal B448C bus, where its RISC core executes ANSI/IEEE functions—overcurrent, earth-fault, or sequence components—before latching outputs to binary modules such as the 216AB61 for tripping or signaling. It interacts natively with ABB’s Relion or Procontrol ecosystems, propagating events over RS-423 to HMIs or SCADA for timestamped replays, with up to 256 MB RAM buffering disturbances at 1 ms resolution. In a bay assembly, it slots alongside power converters like the 216NG62, its firmware—tuned via PCM600—auto-validating setpoints on boot, while galvanic isolation quarantines noise from CT/VT fronts.

Engagement with companions is crisp: link to a 216DB61 input board, and it’s fusing external contacts for nuanced logic, with self-tests flagging bus integrity through LED cues that mirror to remote dashboards. Redundancy options include duplex mounting for failover under 5 ms, and its modular footprint—per IEC 60255—scales from single-relay pods to networked clusters in 800xA extensions. Nestled in the mid-stack—above field acquisition but below supervisory abstraction—the ABB 216VC62A facilitates distributed smarts, its Profibus DP extensions easing grafts onto Modbus gateways for third-party PLCs. For transitional setups blending Procontrol classics with Ethernet backbones, its protocol agility curtails custom layers, letting you hone protection curves over handshaking hassles.

- 216vc62a

| Specification | Details |

|---|---|

| Model Number | 216VC62A |

| Brand | ABB |

| Type | Processor Unit Board |

| Input Voltage | 24 V DC |

| Operating Temp Range | -10°C to +55°C |

| Mounting Style | Rack / Backplane |

| Dimensions | 250 x 150 x 50 mm |

| Weight | 1.0 kg |

| Interface/Bus | B448C Internal Bus, RS-423 |

| Compliance | CE, RoHS, IEC 60255, SIL 2 |

| Supported Protocols | Modbus RTU, Profibus DP |

| Typical Power Draw | 6 W |

Deploying the ABB 216VC62A instills a reliability quotient calibrated for the pulse of protective processing, where its RISC efficiency and thermal safeguards sustain algorithm fidelity through EMI barrages or ambient jolts, yielding performance consistency that discriminates faults from phantoms—crucial in feeder relays where nuisance trips notch availability. In protection chains exposed to arc flashes, this means operators who dissect sequences from buffers, not breadcrumbs, with curve adaptability that holds pickups steady without the hysteresis of older DSPs—directly paring the outage tallies your MTBF metrics exalt.

Integration unfolds with consultative clarity, paring engineering overhead by auto-mapping buses in PCM600; layer on an I/O expander, and it’s validating thresholds in a session, not a sprint, while self-auditing routines surface drifts for recal-free longevity. Engineered for the tenure of relay relapses, the ABB 216VC62A cultivates maintenance efficiency through embedded traces that forecast overloads, elongating service windows and curtailing the cycle of tear-downs that sideline safeguards. In the broader arc, it nurtures an automation fabric resilient to expansions, where adding harmonic adjuncts amplifies coverage without eroding core responsiveness, securing long-term performance that syncs with capex prudence and opex agility.

Power engineers rely on the ABB 216VC62A for feeder overcurrent relays, crunching phase data in real time to isolate shorts amid load volatility—its rapid bus dispatches ensure trip precision, upholding critical system uptime in process control environments that brook no blackout blinks. In offshore wind converters, it governs excitation protections against torque spikes from gusts; here, vibration-hardened processing maintains high reliability, interfacing with shaft encoders for seamless synchronization in salt-laced settings.

Steel arc furnaces harness it in electrode regulators, evaluating current discrepancies to interlock during melts—fast data cycles filter thermal noise, integrating into DCS for oversight that sustains continuous uptime without thermal runaway risks. Across utilities, renewables, and heavy process—the ABB 216VC62A fortifies deployments craving unyielding vigilance and adaptive industrial automation.

216VC62A HESG324442R13 – Refined revision for elevated throughput in denser protection schemes.

216DB61 HESG324015R100 – Input companion module for external signal ingestion in relay logic.

216AB61 HESG324017R100 – Output relay unit, tailored for trip command routing from processor cues.

216NG63A HESG441635R1 – Auxiliary power converter add-on for stable DC feeding in stacks.

216EA61B HESG324258R3 – A/D converter board for analog-to-digital handoffs in front-ends.

GVC736CE01 3BHE006980R0101 – Gate drive interface for motor control extensions.

216NG62A HESG441634R1 – DC/DC unit variant for redundant battery isolation paths.

Prior to seating the ABB 216VC62A in its carrier, audit the B448C bus integrity with a continuity probe—loose terminations can seed intermittent dropouts, so spec-check against the rack diagram from ABB’s archive. Assess cabinet humidity too; above 80% RH without dehumidifiers risks condensation on the board edges, so integrate silica packs if your locale swings damp—pair that with a firmware snapshot to baseline against the latest patch, running a dry simulation of pickup logic to flag config clashes. Grounding loops warrant a once-over as well; stray potentials amplify noise, so loop a milliohmmeter across chassis ties.

With it operational, maintenance adopts a rhythm of informed checks over blanket overhauls. Fortnightly scans of the status ports via RS-423 can unearth cycle elongations, triggering a targeted bus sweep for capacitance creeps. Biannually, demount for connector audits—clean with isopropyl if oxidation hints emerge, and re-torque to 0.6 Nm to defy settling from operational hums. Anchor an annual deep dive with software exports: replay fault scenarios, recalibrate setpoints if variance tops 0.5%, and log for trend spotting like gradual RAM wear. In EMI-saturated zones, shield inspections every quarter fortify against ingress, but keep it light—these protocols tap the unit’s innate reporting to preserve your process control’s edge without undue wrench time.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626