Description

| Parameter | Details |

|---|---|

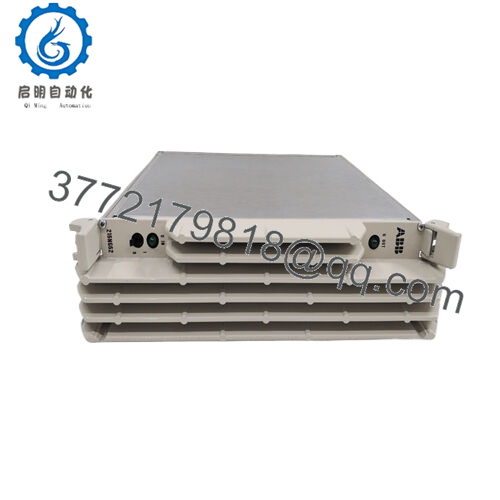

| Model | ABB 216NG62A |

| Type | Analog Input Module |

| Input Range | 4–20 mA, configurable |

| Channels | 8 isolated channels |

| Power Supply | 24 VDC nominal |

| Communication | INFI 90 compatible |

| Temperature Range | -20°C to +60°C |

| Mounting | DIN-rail or chassis mount |

| Diagnostics | LED indicators for input status and fault detection |

Now, one thing worth noting: the grounding sensitivity on this model is tight. I’ve seen signal instability in installations that skipped proper shield terminations. Once you bond everything correctly and isolate the analog grounds, this thing is rock-solid.

- 216NG62A

ABB 216NG62A – A Story from the Field

I first came across the ABB 216NG62A around 2017, back when we were modernizing a power plant control system in Indonesia. The plant had been running on a mix of vintage ABB and third-party modules, and honestly, it was a nightmare to keep stable. When we replaced part of the signal conditioning network with a set of 216NG62A units, things just clicked. Stable analog inputs, smooth communication, and — the most impressive part — absolutely no random signal drift even after six months in that humid, coastal environment.

Real-World Applications

The 216NG62A isn’t flashy, but it’s the kind of module that quietly does its job for decades. I’ve seen it used in oil refineries, paper mills, and especially in combined-cycle power stations. In one chemical plant in Texas, we had twelve of these units monitoring process variables like pressure and flow — all tied into an ABB INFI 90 DCS backbone. The operators there still swear by it because it never gave false readings, even with noisy transmitters and aging cabling.

Technical Specifications (Engineer’s View)

| Parameter | Details |

|---|---|

| Model | ABB 216NG62A |

| Type | Analog Input Module |

| Input Range | 4–20 mA, configurable |

| Channels | 8 isolated channels |

| Power Supply | 24 VDC nominal |

| Communication | INFI 90 compatible |

| Temperature Range | -20°C to +60°C |

| Mounting | DIN-rail or chassis mount |

| Diagnostics | LED indicators for input status and fault detection |

Now, one thing worth noting: the grounding sensitivity on this model is tight. I’ve seen signal instability in installations that skipped proper shield terminations. Once you bond everything correctly and isolate the analog grounds, this thing is rock-solid.

Installation Notes & Gotchas

When I trained new technicians on this module, I always told them: “Take five extra minutes to check your terminal torque.” The terminals on the 216NG62A can loosen slightly if over-tightened — not a design flaw, just sensitive machining. Another pro tip: use ferruled leads if you’re doing field replacements; it reduces the chance of contact degradation over time.

And one more detail — ABB’s documentation for this particular series is a bit on the “classic” side. Don’t expect step-by-step photos. But once you understand the channel mapping and DIP switch layout, you can configure it blindfolded.

Performance and Reliability

If I had to summarize the 216NG62A in one word, it’d be bulletproof. I’ve worked with newer modules that promise fancy self-diagnostics and web interfaces, but they don’t last half as long in harsh industrial conditions. The 216NG62A just endures. Its internal isolation design and signal filtering make it perfect for environments where electrical noise can kill lesser boards.

The only real drawback? Limited flexibility. It’s not meant to handle smart HART signals or digital overlays. But if all you need is rock-steady analog input processing, this is your guy.

Maintenance Insights

One of the best features is how forgiving it is to service. You can hot-swap the 216NG62A in a redundant INFI 90 chassis without dropping the entire control loop. I remember once replacing a faulty channel card during production — didn’t even need to shut down the DCS. Try that with some of the newer “smart” systems, and you’ll trigger half a dozen alarms.

Also, the module’s front indicators save a ton of troubleshooting time. Red for fault, green for healthy input — simple and effective. If only every manufacturer stuck to that logic.

Comparison with Other Models

I’ve often compared the 216NG62A to the older 216NG42A series. The newer model offers better isolation and slightly faster scan times. It’s also less prone to calibration drift. Against modern competitors like Honeywell’s AI modules, the ABB still holds its ground — fewer frills, but unmatched longevity.

Final Thoughts

If you’re running an ABB INFI 90 or Bailey DCS, and reliability is what keeps your plant safe, the 216NG62A is a must-have. It’s not the kind of component that shows up in glossy brochures, but it’s the one that keeps the control room lights green year after year.

And here’s the thing — when you’ve been in this business long enough, you learn to appreciate gear that just works. The ABB 216NG62A is one of those rare modules that earns your respect by staying invisible: no errors, no reboots, no drama.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626