Description

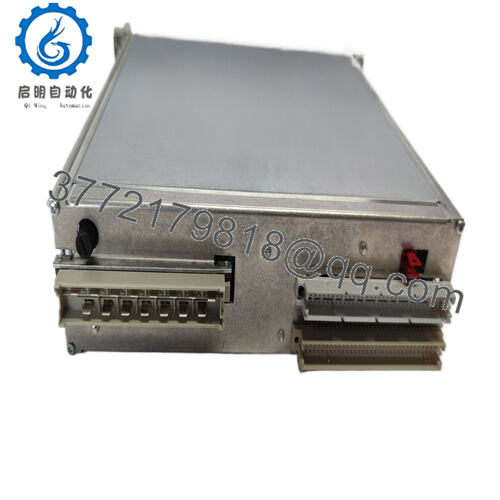

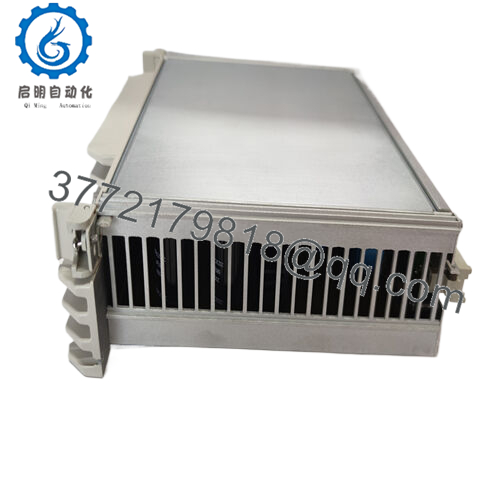

216NG62A HESG441634R1K HESG216876

216NG62A HESG441634R1K HESG216876

Technical Highlights (Engineer’s Snapshot)

| Specification | 216NG62A | HESG441634R1K | HESG216876 |

|---|---|---|---|

| Type | Analog Input Module | I/O Processor Board | Controller Interface Module |

| Channels | 8 isolated | Multi-channel I/O handling | System communication and redundancy |

| Input Range | 4–20 mA configurable | Mixed analog/digital | Inter-module signal bus |

| Voltage Supply | 24 VDC nominal | 5 V logic / 24 V field | 24 VDC |

| Operating Temp. | -20 °C to +60 °C | -10 °C to +55 °C | -20 °C to +60 °C |

| Mounting | Rack-based (INFI 90 chassis) | Main controller rack | Redundant controller frame |

| Communication | INFI 90 / Bailey protocol | INFI 90 bus | Controller backplane |

I always appreciated that ABB didn’t overcomplicate things. DIP switches, clear labels, and predictable addressing — unlike some other brands where you need a proprietary tool just to check a signal.

ABB 216NG62A / HESG441634R1K / HESG216876 — The Unshakable Backbone of an Old Bailey System

If you’ve ever walked into an old turbine control room and seen that unmistakable beige ABB rack humming quietly, there’s a good chance it had a 216NG62A sitting right in the middle of it. I can still picture one in a combined-cycle plant we commissioned back in 2015. It wasn’t glamorous — no fancy diagnostics, no touchscreen interface — but it ran like a workhorse.

That plant ran a hybrid DCS setup: ABB’s INFI 90 core with a few new Ethernet-based subsystems. Every time someone suggested replacing the old HESG441634R1K or HESG216876 units, the maintenance team would just shake their heads. “These things don’t die,” one of the senior operators told me — and he wasn’t wrong. We had modules there older than some of the engineers on site.

Why These Modules Still Matter

You might think the 216NG62A, HESG441634R1K, and HESG216876 are relics, but in industrial automation, reliability beats novelty any day. I’ve seen modern systems crash from a firmware update, while these ABB modules kept feeding clean analog signals into the control logic without missing a beat.

Their secret? Simple, isolated signal design. Each channel has robust galvanic separation, filtering out the electrical noise that plagues plants running big motors, turbines, or high-current drives. They don’t try to “think” — they just measure.

When you’ve got hundreds of loops and only a few minutes to bring a line back up after a maintenance stop, you start valuing gear that doesn’t throw surprises at you.

Field Performance — From the Trenches

There’s a refinery in Abu Dhabi that’s still running 12 of these HESG441634R1K modules, handling over 250 analog points from flow transmitters and RTDs. Last I checked, they had logged zero input failures in three years. That’s a better record than most modern systems boasting “diagnostic AI.”

And don’t get me started on the HESG216876 — that little board is like a silent supervisor. It keeps the communication heartbeat steady between controller modules, even when you swap or hot-replace a unit. Once, during a shift in a sugar plant in Brazil, I pulled one mid-operation (with redundancy, of course) — not a single alarm went off. Smooth as butter.

Installation and Setup Lessons

If you’re retrofitting one of these into an older Bailey system, here’s what you need to know:

- Clean grounding is non-negotiable. ABB modules like the 216NG62A are sensitive to ground potential differences.

- Always verify the backplane connector pins — ABB’s older racks can oxidize over time, leading to intermittent signals.

- For the HESG216876, keep your firmware EEPROM handy. Each revision interacts differently with redundant controllers; mismatches can cause phantom communication drops.

These details sound minor, but they’re what separate a smooth restart from a 4-hour downtime.

Performance Pros & Cons (From Real-World Use)

Pros:

- Practically indestructible hardware — built for 24/7 industrial duty.

- Excellent noise rejection and isolation between channels.

- Backward compatibility with older ABB/Bailey systems.

- Predictable behavior — no surprise firmware or config quirks.

Cons:

- Lacks modern diagnostic reporting (you’ll need your multimeter, not a GUI).

- ABB documentation for these older models is terse. You learn more from field notes than manuals.

- Not compatible with newer digital fieldbuses like HART or Profibus without converters.

Still, when reliability trumps convenience — like in nuclear or petrochemical control rooms — these modules remain unmatched.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626