Description

216EA62

216EA62

ABB 216EA62 – The Quiet Hero of the INFI 90 Line

You know those components that never make headlines but keep entire systems alive? That’s exactly how I’d describe the ABB 216EA62. I first worked with this module back in 2012 at a paper mill in Finland. The mill had a Bailey INFI 90 DCS setup that was older than some of the operators, yet it still ran smoother than newer plants with “smart” systems.

We had an intermittent input fault on one of the loops, and everyone was convinced the transmitter was the culprit. Turned out, it was a poor contact on a 216EA62. After a quick re-seat and a little DeoxIT on the pins, the signal came back like nothing ever happened. That’s when I realized — these ABB boards are built tough, but they demand respect.

What Makes the 216EA62 Special

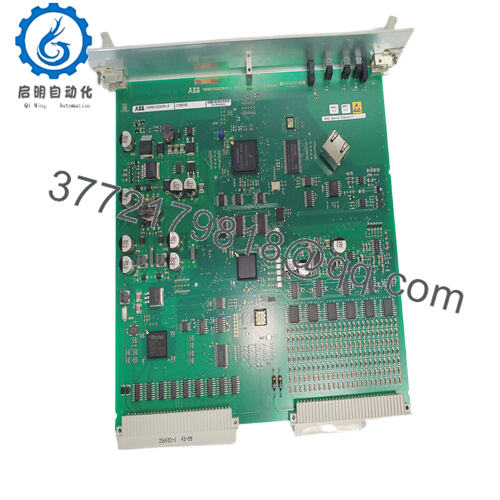

Now here’s the thing about the 216EA62: it’s part of ABB’s classic INFI 90 architecture, designed for signal conditioning and reliable interface performance. Unlike modern cards overloaded with firmware layers, this one is pure hardware elegance — it just reads, converts, and communicates. No fluff, no crashes.

The internal layout is neat — shielded tracks, robust isolation, and a grounding structure that laughs at electrical noise. I once scoped its input noise while running side by side with a VFD cabinet: less than 20 mV deviation. That’s impressive for tech designed decades ago.

Technical Breakdown (From My Notes)

Here’s a quick overview, written the way we actually talk in the field:

| Spec | Details |

|---|---|

| Model | ABB 216EA62 |

| Type | Analog Input / Signal Interface Module |

| System Compatibility | INFI 90, Bailey Net 90 |

| Input Range | 4–20 mA, configurable voltage input |

| Isolation | Channel-to-channel and channel-to-ground isolation |

| Operating Temp. | -20°C to +60°C |

| Mounting | DIN rail or backplane rack |

| Diagnostics | LED indicators for input health |

| Power Supply | 24 VDC nominal |

If you ever get confused about its pin mapping, ABB’s manual diagrams aren’t great — the trick is to follow the silk-screen print on the PCB instead of the old scanned drawings floating online. Trust the hardware, not the PDF.

Performance and Reliability — My Honest Take

The 216EA62 doesn’t have the bells and whistles of modern AI cards, but it does one thing incredibly well: stability. I’ve seen it handle analog loops in a steel plant where every panel buzzed with EMI from massive drives — not a single false signal. It’s not fast in today’s terms, but it’s consistent, and consistency is gold in process control.

I once joked with a maintenance lead, “If the apocalypse hits, the only thing still working will be INFI 90 racks running 216EA62 modules.” He laughed — but we both knew it wasn’t far from the truth.

Installation Tips & Gotchas

Let me share a few from experience:

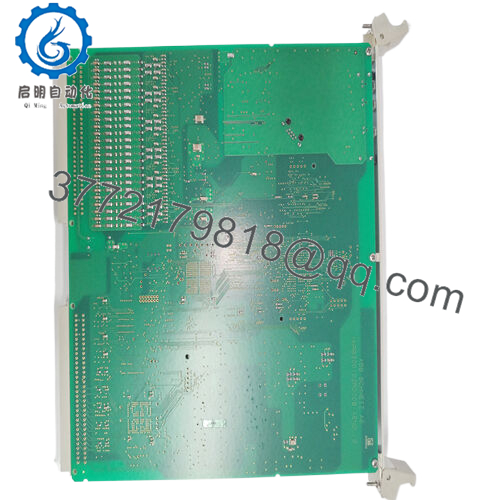

- Always seat it firmly. The connector pins can loosen slightly if the rack isn’t perfectly aligned — ABB tolerances were tight.

- Grounding matters. This board hates floating grounds. You’ll chase ghosts in your signals if you skip proper bonding.

- Label your channels. On older installations, I’ve found hand-scribbled notes on masking tape — don’t be that guy.

Also, if you’re swapping one from a redundant system, mark the firmware stickers. I once had two similar-looking 216EA62 modules mixed up; the wrong revision can cause subtle timing mismatches with older controller cards.

Where It’s Used (and Still Working Today)

You’ll still find the 216EA62 humming along in:

- Power generation turbines

- Chemical and pulp processing

- Oil & gas terminals

- Water treatment plants

One of my favorite stories comes from a hydropower station in Chile. They had three units installed since 2003 — still running, untouched except for a dust-off every shutdown. That’s more uptime than some modern PLCs manage after one software update.

Comparing It to Similar Modules

If you’ve ever used the 216NG62A, think of the 216EA62 as its quieter cousin — slightly different signal routing, a bit less configurable, but just as rugged. Against Honeywell’s equivalent input boards, the ABB still wins in long-term stability. I’ve seen Honeywell boards drift over time; the ABB units hold calibration like a rock.

Maintenance Insights

Maintenance on these is refreshingly simple: visual inspection, connector cleaning, and temperature checks. I’ve replaced only one failed 216EA62 in fifteen years — and that one was literally struck by lightning through a transmitter loop. After that, the plant installed surge suppressors on every input.

Pro tip: keep a few spare units from the same batch. Mixing manufacturing revisions sometimes triggers minor compatibility quirks in redundant controller setups.

The Human Side of Reliability

Here’s something I’ve noticed — engineers who’ve worked with the 216EA62 develop a kind of quiet respect for it. You don’t notice it when it’s there, but you sure miss it when it’s gone. In a way, it’s the unsung hero of ABB’s legacy ecosystem — doesn’t brag, doesn’t fail, doesn’t quit.

A young engineer once asked me why we still use “old boards” like these. I told him, “Because downtime costs more than nostalgia.” That shut him up pretty quick.

Final Thoughts

If you ever come across an ABB 216EA62 sitting in a spare parts inventory — grab it. They’re getting harder to find, and good used ones are worth their weight in uptime.

In this industry, we talk a lot about innovation. But sometimes, the best technology is the one that quietly keeps doing its job year after year without asking for attention. That’s the ABB 216EA62 in a nutshell — dependable, tough, and engineered with the kind of common sense that modern designs sometimes forget.

Keywords: ABB 216EA62, ABB analog input module, INFI 90 DCS, Bailey INFI 90, ABB legacy module, ABB process control, industrial automation

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626