Description

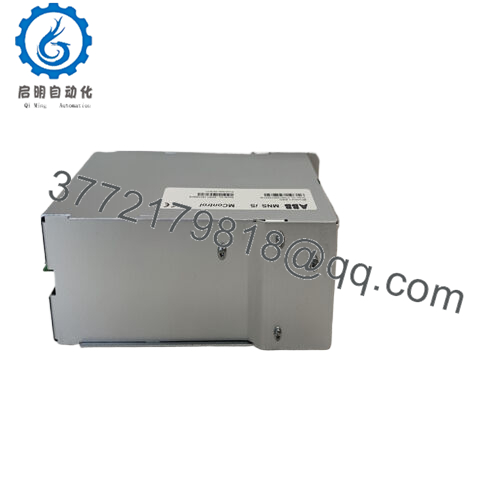

| Model Number | 1TGE120011R1001 |

| Brand | ABB |

| Type | PROFINET-Enabled AC Variable Frequency Drive (VFD) |

| Input Voltage | 3-phase, 380V–480V AC (±10%) |

| Output Voltage | 3-phase, 0V–input voltage |

| Output Frequency | 0 Hz–500 Hz |

| Rated Power | 1.5 kW (2 HP) |

| Rated Current | 3.8 A (at 400V, 50Hz) |

| Operating Temp Range | -10°C to 50°C (14°F to 122°F) (without derating) |

| Mounting Style | DIN Rail (35mm, EN 60715) or Panel Mount |

| Dimensions | 140mm (W) x 210mm (H) x 150mm (D) |

| Weight | 2.9 kg (6.4 lbs) |

| Interface/Bus | PROFINET RT/IRT (100 Mbps Ethernet port); Modbus RTU (secondary) |

| Compliance | CE, UL, CSA, IEC 61800-5-1, PROFINET Certified |

| Control Modes | Sensorless Vector, V/F Control, Torque Control |

| Protection Features | Overcurrent, overvoltage, undervoltage, thermal overload, short-circuit |

1TGE120011R1001

The ABB 1TGE120011R1001 functions as a sensorless vector control VFD with built-in PROFINET RT (Real-Time) support, designed to act as a native node in PROFINET automation networks. Unlike the base ABB 1TGE120011R1000 (which requires optional PROFINET add-ons), this variant includes a dedicated PROFINET port that enables direct communication with PROFINET controllers (e.g., Siemens S7-1200/S7-1500 PLCs) at speeds up to 100 Mbps. It supports PROFINET features like IRT (Isochronous Real-Time) for time-critical applications (e.g., synchronized conveyor belts) and DCP (Discovery and Basic Configuration Protocol) for auto-detection and quick setup—eliminating manual IP address configuration.

1TGE120011R1001

The VFD retains the base model’s core capabilities: variable speed control (0 Hz–500 Hz), soft-start functionality, and comprehensive protection (overcurrent, overvoltage, thermal overload), but adds PROFINET-specific benefits like remote parameter adjustment, real-time fault logging, and integrated process data exchange. By mounting onto a standard 35mm DIN rail or panel, it fits into space-constrained PROFINET control cabinets while providing easy access to its PROFINET port and backlit keypad for local configuration. In the automation stack, the ABB 1TGE120011R1001 acts as a bridge between the PROFINET control layer and the motor: it receives real-time speed/torque commands from the PLC, feeds back operational data (e.g., current, temperature, fault codes) to the network, and ensures motor performance aligns with the broader system’s needs—all without latency or gateways.

1TGE120011R1001

Main features and advantages:

Choosing the ABB 1TGE120011R1001 delivers tangible value that streamlines PROFINET integration, enhances remote visibility, and reduces operational costs. Engineered for seamless connectivity, its native PROFINET support eliminates the need for external gateways—cutting hardware costs by \(200–\)500 per drive and reducing points of failure in the network. For Siemens-focused teams, the VFD’s compatibility with TIA Portal (Siemens’ automation software) allows for centralized configuration: engineers can program, monitor, and troubleshoot the ABB 1TGE120011R1001 alongside other PROFINET devices in a single interface, reducing training time and configuration errors. The PROFINET RT/IRT support also enables real-time synchronization—critical for applications like automotive assembly lines, where multiple conveyors and robots must operate in lockstep to avoid production delays.

Additionally, the ABB 1TGE120011R1001 retains the base model’s energy-saving capabilities, cutting consumption by 20–50% in variable-demand applications (e.g., PROFINET-controlled HVAC fans). Its soft-start feature reduces motor inrush current by up to 80%, extending motor life by 30% and lowering maintenance costs. Unlike VFDs with retrofitted PROFINET modules, this variant’s integrated PROFINET hardware ensures reliable communication even in high-noise industrial environments—preventing data dropouts that cause unplanned downtime. The drive’s compliance with PROFINET Certification (per PI International) also guarantees interoperability with other PROFINET devices, eliminating the risk of compatibility issues during system expansion.

Application fields:

The ABB 1TGE120011R1001 excels in PROFINET-dominated industries where real-time integration and synchronization are mission-critical. In automotive manufacturing, it’s used with Siemens S7-1500 PLCs to control conveyor motors in body assembly lines: PROFINET IRT ensures all conveyors operate at precisely coordinated speeds, preventing misalignment of car parts and reducing rework. In pharmaceutical production, it integrates with PROFINET-based batch control systems to regulate mixer motors: remote parameter adjustment via TIA Portal allows for quick recipe changes without physical access to the drive, maintaining sterile conditions. In food and beverage processing, it controls PROFINET-connected pump motors for ingredient dosing: real-time data feedback (e.g., pump speed, current draw) to the SCADA system ensures precise ingredient ratios, reducing waste and ensuring compliance with FDA standards. Across all these use cases, the ABB 1TGE120011R1001’s ability to act as a native PROFINET node makes it a trusted solution for modern, connected factories.

Related products:

ABB 1TGE120012R1001 – PROFINET-enabled variant with higher power (2.2 kW / 3 HP) for larger PROFINET-controlled motors (e.g., industrial mixers).

ABB 1TGE120010R1001 – PROFINET-enabled variant with lower power (0.75 kW / 1 HP) for small PROFINET devices (e.g., laboratory pumps).

ABB 1TGE120011R1000 – Base model (no built-in PROFINET) for non-PROFINET environments (e.g., Modbus-only systems).

ABB 1TGE120011R1002 – PROFINET + high-temperature variant (-20°C to 60°C) for PROFINET applications in harsh heat (e.g., foundry conveyors).

ABB 1TGE120011R1003 – PROFINET + IP54 enclosed variant for dusty/wet PROFINET environments (e.g., dairy processing).

ABB 1TGE120011R1004 – PROFINET + regenerative braking variant for energy recovery in PROFINET-controlled elevators or cranes.

ABB 1TGE120011R1005 – PROFINET + input filter variant for reducing harmonics in sensitive PROFINET networks (e.g., data center HVAC).

ABB 1TGE120011R1006 – PROFINET + redundant power variant for safety-critical PROFINET systems (e.g., hospital life support pumps).

Installation and maintenance:

Before installing the ABB 1TGE120011R1001, confirm the PROFINET network’s requirements: ensure the PLC (e.g., Siemens S7-1200) supports PROFINET RT/IRT and that the network has available node addresses. Verify input voltage/phase (3-phase, 380V–480V) and motor compatibility (max 1.5 kW / 400V) to avoid overloading. Mount the drive in a well-ventilated cabinet with 50mm clearance on all sides; derate by 10% for each 5°C above 50°C. For PROFINET wiring, use shielded Cat5e/Cat6 cable (max length 100m) and ground the shield at both ends to reduce EMI. In TIA Portal, use DCP to auto-detect the drive and assign an IP address—avoid manual configuration errors.

For ongoing maintenance, monitor PROFINET communication status via the drive’s display or TIA Portal; check for error codes like “PN-Link Down” (indicating a network issue). Clean cooling fans quarterly with compressed air, and update the drive’s firmware via TIA Portal to ensure PROFINET feature compatibility. If a fault occurs, use PROFINET’s built-in diagnostics to trace issues (e.g., packet loss) before restarting the drive.

Other ABB product models:

ABB 745745

ABB 746376

ABB 07AC91

ABB 07KR31 FPR36000227R1202-O

ABB 07KT92

ABB 07KT92 GJR5250500R0202

ABB 07KT93

ABB 07KT93

ABB 07KT93 GJR5251300R0101

ABB 07KT94 GJR5252100R3261

ABB 07kt94g GJR5252100R0261

ABB 07KT94-S H3 GJR5252100R2201

ABB 07KT98 GJR5253100r0272

ABB 07KT98 GJR5253100R0272

ABB 07KT98 GJR5253100R0272

ABB 07MK92 GJR5253300R1161

ABB 086318-002

ABB 086329-004

ABB 086329-004

ABB 086329-004 includes SMI board (806339-001)

ABB 086339-501

ABB 086345-504

ABB 086348-001

ABB 086348-001

ABB 086348-001

ABB 086351-003

ABB 086351-004-C

ABB 086362-001

ABB 086362-001

ABB 086370-001

ABB 086370-001

ABB 086444-005

ABB 086444-005

ABB 086444-005

ABB 128057-204 086345-504 frame

ABB 129740-002

ABB 129740-002

ABB 129740-002

ABB 1336-BDB-SP79D

ABB 16NG63A HESG441635R1 HESG216879/K

ABB 1756-L72

ABB 1KHL178016R0001F PSM03

ABB 1KHL178016R0001F PSM03

ABB 1KHL178016R0001F PSM03

ABB 1KHL178025R0102P COM02

ABB 1KHL178025R0102P COM02

ABB 1KHL178025R0102P COM02

ABB 1MRB150005R1/P

ABB 1MRK000005-380 REG670

ABB 1MRK000508-BD

ABB 1MRK000508-CDr09

ABB 1MRK002122-ABR02

ABB 1MRK002238-CA

ABB 1MRK002311-AAR02

ABB 1MRK002311-AAR02

ABB 1MRK002816-AC

ABB 1MRK004810 RED670

ABB 1MRK004816-AB RET670

ABB 1SAJ520000R0101

ABB 1SCA022079R9050

ABB 1SCA022079R9050 OETL-ZT80A220AC

ABB 1SDA-051116-R1

ABB 1SDA060537R1

ABB 1SDA071666R1

ABB 1SFA619550R1071

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626