Description

| Specification | Detail |

|---|---|

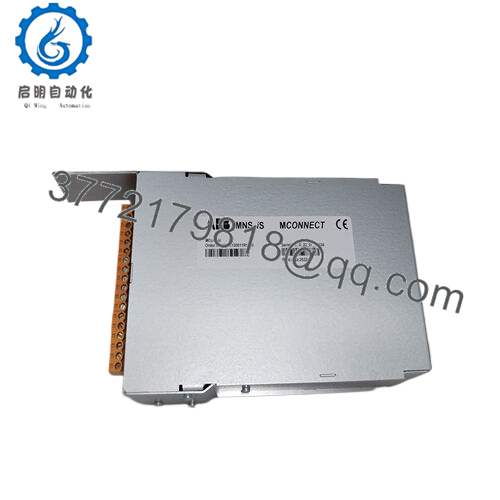

| Model | ABB 1TGE120011R1000 |

| Dimensions | 53x125x260mm |

| Protection Features | Overload, short-circuit, ground fault |

| Metering Capabilities | Motor current, voltage, power, energy |

| Communication Protocols | Modbus, Ethernet |

| Mounting Type | Designed for MNS IS system integration |

| Operating Voltage | 100-240VAC 50/60Hz |

| Output Voltage | 9VDC |

| Weight | Approximately 2.145kg |

| Country of Origin | Sweden |

- 1TGE120011R1000

Product Overview

The ABB 1TGE120011R1000 is a motor and feeder control unit designed for the MNS IS system. This module offers comprehensive protection and control for motors and feeders in low-voltage power distribution systems. With advanced metering capabilities and flexible communication options, it ensures reliable and efficient operation in various industrial applications.

Technical Features & Benefits

- Motor and Feeder Protection: The module provides overload, short-circuit, and ground fault protection for motors and feeders, ensuring the safety and reliability of the power distribution system.

- Advanced Metering Capabilities: It offers metering of motor current, voltage, power, and energy, allowing for detailed monitoring and analysis of system performance.

- Flexible Communication Options: The unit can communicate with other devices using a variety of protocols, including Modbus and Ethernet, facilitating integration into existing control systems.

- Compact and Robust Design: With dimensions of 53x125x260mm, the module is designed to fit seamlessly into the MNS IS system, offering a compact and robust solution for motor and feeder control.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626