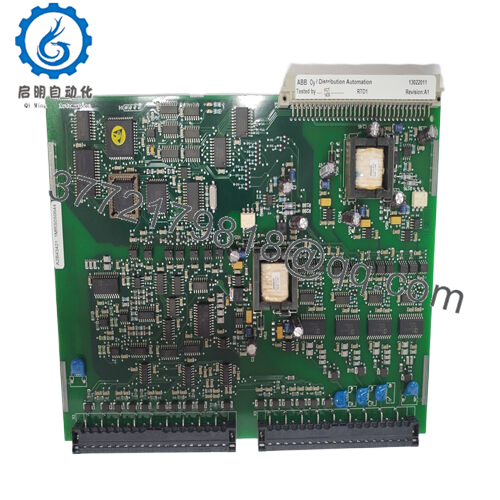

Description

| Model Number | 1MRS050644 |

| Brand | ABB |

| Type | Plug-In Electromechanical Relay (Industrial Control) |

| Input Voltage | 24V DC / 110V AC (coil voltage options) |

| Operating Temp Range | -25°C to 60°C (-13°F to 140°F) |

| Mounting Style | DIN Rail (35mm, per EN 60715) + Plug-In Socket |

| Dimensions | 17.5mm (W) x 85mm (H) x 55mm (D) |

| Weight | 120g (0.26 lbs) |

| Interface/Bus | Terminal Block (screw-type, 6-pin) |

| Compliance | CE, UL, CSA, IEC 61810-1 |

| Supported Protocols | N/A (hardwired control signal) |

| Typical Power Draw | 1.5VA (at 24V DC), 3VA (at 110V AC) |

1MRS050644

The ABB 1MRS050644 functions as a key component in low-voltage industrial control systems, specifically as a plug-in electromechanical relay that connects between control devices (e.g., PLC outputs) and load devices (e.g., contactors, solenoids).

1MRS050644

Unlike generic relays, it leverages ABB’s industrial-grade design to optimize signal transmission: when a control signal (typically 24V DC or 110V AC) energizes the relay’s coil, it triggers a mechanical switch to close or open the load circuit—ensuring fast, consistent actuation with minimal bounce. This design integrates seamlessly with common control architectures, including distributed control systems (DCS) and programmable logic controller (PLC) setups, as it supports standard terminal connections and fits into standard control panel enclosures. The relay also includes built-in surge protection, which shields it from voltage spikes common in industrial environments—critical for maintaining continuous uptime in process control applications. By sitting between the control layer and the load layer, the ABB 1MRS050644 acts as a reliable interface, ensuring that control signals are translated to physical action without degradation or failure.

Main features and advantages:

Choosing the ABB 1MRS050644 delivers practical value that goes beyond basic switching. Engineered for industrial ruggedness, it resists mechanical vibration, dust ingress, and temperature extremes—ensuring long-term performance in harsh plant floor or outdoor control cabinet environments. This durability translates to a longer service life (typically 100,000+ switching cycles) and fewer replacements, reducing maintenance costs and unplanned downtime. For engineers, the relay’s plug-in design simplifies installation and replacement: instead of rewiring the entire circuit, technicians can quickly swap out the relay module—cutting maintenance time by up to 50% compared to hardwired alternatives. The built-in surge protection further reduces operational risk by preventing voltage spikes from damaging the relay or connected load devices, a common issue in factories with heavy machinery.

Additionally, the ABB 1MRS050644 supports dual voltage options (24V DC and 110V AC), which eliminates the need to stock multiple relay types for different control systems—streamlining inventory management and reducing procurement complexity. Unlike low-cost consumer-grade relays, it’s designed to meet IEC 61810-1 safety standards, ensuring it can be used in safety-critical circuits (such as emergency stop systems) without compromising compliance. Its compact DIN rail footprint also saves space in control panels, allowing engineers to fit more components into limited enclosures—a key advantage for retrofits or space-constrained applications.

Application fields:

The ABB 1MRS050644 excels in industries where reliable control circuit switching is mission-critical. In automotive manufacturing, it’s used to switch control signals for robotic arms and conveyor belts, ensuring precise synchronization of assembly steps and preventing costly production jams. Its wide temperature range makes it suitable for outdoor water treatment plants, where it controls pump and valve actuation in fluctuating weather conditions—maintaining consistent water purification processes. In food and beverage facilities, the relay’s dust-resistant design and compliance with food industry safety standards (via UL/CSA certification) make it ideal for switching signals in packaging lines, where contamination risks are low but reliability is high. Across all these use cases, the ABB 1MRS050644 supports continuous uptime—a key requirement in industries where even a 30-minute shutdown can result in tens of thousands of dollars in lost revenue. Its compatibility with standard control signals also makes it versatile, fitting into both legacy and modern automation systems without extensive reengineering.

Related products:

ABB 1MRS050645 – Higher-coil-voltage version (230V AC) for industrial systems using line voltage control signals.

ABB 1MRS050643 – Lower-power variant (1VA at 24V DC) for energy-efficient applications like battery-powered control panels.

ABB 1MRS050646 – Latching relay version (maintains state without continuous power) for backup system control.

ABB 1MRS050647 – Dual-contact version (2x SPST) for applications requiring redundant switching paths.

ABB 1MRS050648 – Socket accessory for 1MRS050644, enabling tool-free relay replacement and wiring protection.

ABB 1MRS050649 – Surge suppression add-on module for extreme voltage spike environments (e.g., mining).

ABB 1MRS050650 – Previous generation relay (1MRS050640 series), compatible with legacy ABB control panels.

ABB 1MRS050651 – LED-indicator variant for visual confirmation of relay actuation in high-visibility control rooms.

Installation and maintenance:

Before installing the ABB 1MRS050644, verify that the control circuit voltage matches the relay’s coil voltage (24V DC or 110V AC) — using the wrong voltage will damage the coil and cause immediate failure. Ensure the DIN rail is clean and securely mounted to the control panel; debris or loose rails can cause vibration-related contact bounce. Check that the relay’s socket (if used) is wired correctly per ABB’s wiring diagram: reversing coil polarity won’t damage the relay but will prevent proper actuation. For outdoor or dusty environments, confirm the control panel has adequate sealing to protect the relay from ingress—while maintaining airflow to prevent overheating.

For ongoing maintenance, inspect the relay’s terminal connections quarterly for tightness and corrosion, especially in humid areas; loose connections can cause arcing and contact wear. Test the relay’s switching function annually using a multimeter: measure continuity across the load contacts when the coil is energized and de-energized to ensure no contact degradation. Replace the relay if switching time exceeds 10ms (per ABB’s specs), as delayed actuation can disrupt control system timing.

Other ABB product models:

ABB 745745

ABB 746376

ABB 07AC91

ABB 07KR31 FPR36000227R1202-O

ABB 07KT92

ABB 07KT92 GJR5250500R0202

ABB 07KT93

ABB 07KT93

ABB 07KT93 GJR5251300R0101

ABB 07KT94 GJR5252100R3261

ABB 07kt94g GJR5252100R0261

ABB 07KT94-S H3 GJR5252100R2201

ABB 07KT98 GJR5253100r0272

ABB 07KT98 GJR5253100R0272

ABB 07KT98 GJR5253100R0272

ABB 07MK92 GJR5253300R1161

ABB 086318-002

ABB 086329-004

ABB 086329-004

ABB 086329-004 includes SMI board (806339-001)

ABB 086339-501

ABB 086345-504

ABB 086348-001

ABB 086348-001

ABB 086348-001

ABB 086351-003

ABB 086351-004-C

ABB 086362-001

ABB 086362-001

ABB 086370-001

ABB 086370-001

ABB 086444-005

ABB 086444-005

ABB 086444-005

ABB 128057-204 086345-504 frame

ABB 129740-002

ABB 129740-002

ABB 129740-002

ABB 1336-BDB-SP79D

ABB 16NG63A HESG441635R1 HESG216879/K

ABB 1756-L72

ABB 1KHL178016R0001F PSM03

ABB 1KHL178016R0001F PSM03

ABB 1KHL178016R0001F PSM03

ABB 1KHL178025R0102P COM02

ABB 1KHL178025R0102P COM02

ABB 1KHL178025R0102P COM02

ABB 1MRB150005R1/P

ABB 1MRK000005-380 REG670

ABB 1MRK000508-BD

ABB 1MRK000508-CDr09

ABB 1MRK002122-ABR02

ABB 1MRK002238-CA

ABB 1MRK002311-AAR02

ABB 1MRK002311-AAR02

ABB 1MRK002816-AC

ABB 1MRK004810 RED670

ABB 1MRK004816-AB RET670

ABB 1SAJ520000R0101

ABB 1SCA022079R9050

ABB 1SCA022079R9050 OETL-ZT80A220AC

ABB 1SDA-051116-R1

ABB 1SDA060537R1

ABB 1SDA071666R1

ABB 1SFA619550R1071

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626