Description

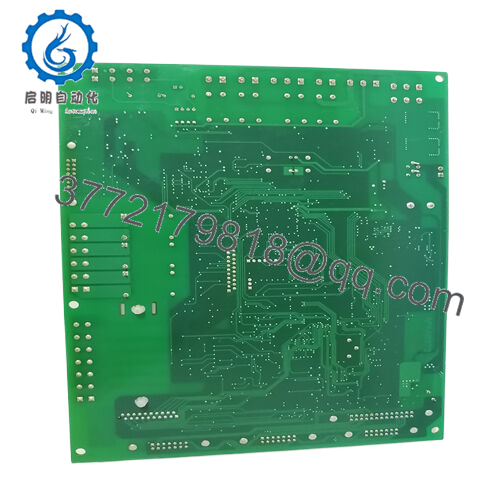

ABB 110 TAS.580.0540G00 is an advanced industrial control module and a key component in ABB’s comprehensive industrial automation solution suite. It serves as the central processing unit of the control system, receiving data from various sensors, processing it according to pre programmed logic, and then sending instructions to actuators.

ABB110 TAS.580.0540G00

This module has high adaptability and can be integrated into different types of control system architectures, whether they are simple independent systems or complex distributed networks. For example, in a distributed control system (DCS), ABB 110 TAS.580.0540G00 serves as a critical node to communicate with other modules and devices in the network. It ensures smooth data flow and coordinated control, enabling the entire system to operate smoothly.

ABB110 TAS.580.0540G00

Main features and advantages:

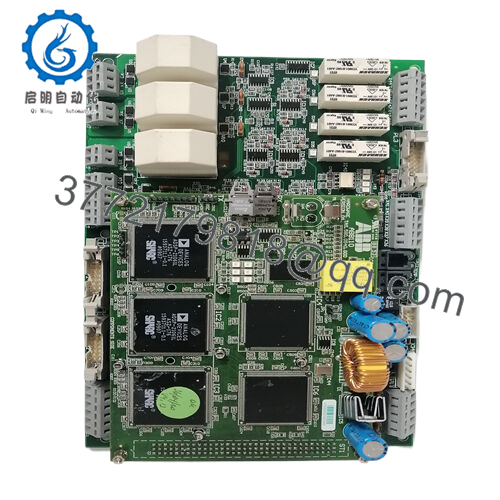

Equipped with a high-performance processor, it can execute complex control programs in milliseconds. On high-speed production lines, this speed ensures that mechanical equipment can immediately respond to changes in product specifications or production requirements, maintaining high productivity.

The hardware design of this module is both robust and compact. It can operate reliably under harsh conditions in industrial environments and withstand high levels of electrical noise, vibration, and temperature fluctuations. Its compact size makes it easy to install in control cabinets, even in spaces with limited space. This not only saves space, but also makes maintenance and upgrades more convenient.

In terms of compatibility, ABB 110 TAS.580.0540G00 performs well. It supports multiple industry standard communication protocols, including Ethernet, Modbus, and Profibus. This means that it can be easily integrated with other components of the control system, such as sensors, actuators, and other control modules. Whether you want to connect it with legacy equipment in old factories or with the latest smart devices in modern facilities, ABB 110 TAS.580.0540G00 can easily handle it.

In terms of long-term reliability, ABB has designed and manufactured ABB 110 TAS.580.0540G00 using high-quality components. These components have been carefully selected to withstand long-term continuous use. This module also has a built-in self diagnostic function that can detect and report potential issues before they cause system failures. This proactive maintenance approach helps to minimize downtime and ensure that the industrial processes it supports can continue to operate efficiently.

ABB110 TAS.580.0540G00

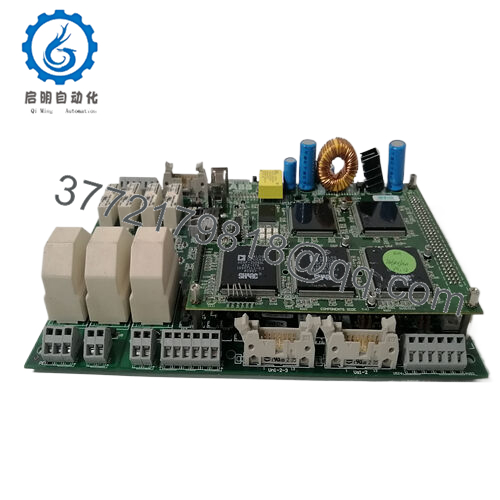

Technical specifications:

Model 110 TAS.580.0540G00

Brand ABB

Type: Industrial Control Module

Power supply 220V

Working temperature -20 ° C to 60 ° C

Installation method: DIN rail installation

Size [insert actual size if available]

Weight 1.1 kg

Ethernet interface RS – 485、Modbus、Profibus

Certification CE, UL

Output frequency 30 kHz

Protection level IP20

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

Related products:

ABB AI810 Analog Input Module – This module can be connected to ABB 110 TAS.580.0540G00, enabling the control module to receive and process analog signals from various sensors such as temperature and pressure sensors. This expands the system’s ability to monitor and control processes that rely on simulated data.

ABB AO810 Analog Output Module – Used in conjunction with ABB 110 TAS.580.0540G00, it outputs analog signals to actuators to achieve precise control of equipment such as variable speed motors or control valves in industrial processes.

ABB DI810 Digital Input Module – facilitates the connection of digital sensors to ABB 110 TAS.580.0540G00, enabling the module to receive digital signals indicating the binary status of devices such as switches and relays.

ABB DO810 Digital Output Module – sends digital output signals from ABB 110 TAS.580.0540G00 to control digital actuators in industrial applications, such as solenoid valves and contactors.

ABB Communication Gateway Module – can be integrated with ABB 110 TAS.580.0540G00 to enhance communication capabilities, especially when dealing with complex network topologies or requiring interfaces with different types of networks.

ABB power module – ensures stable power supply for ABB 110 TAS.580.0540G00 and other connected modules, ensuring reliable operation even in the event of power fluctuations.

ABB Human Machine Interface (HMI) module – provides an interface for operators to interact with the system controlled by ABB 110 TAS.580.0540G00. It is convenient for monitoring process parameters and adjusting control settings.

Installation and maintenance:

It is crucial to ensure a suitable installation environment before installing ABB 110 TAS.580.0540G00. The control cabinet installed should have sufficient ventilation to prevent overheating. Due to the module being powered by a 220V power supply, please verify if the power supply is stable and the output voltage is correct. Grounding is also crucial. Ensure that the module is properly grounded to prevent electrical surges and interference that may interfere with its operation. In addition, check the available space inside the cabinet; The module should be installed in an area with sufficient margin for future maintenance.

For maintenance, it is recommended to conduct regular visual inspections. Check for any signs of physical damage, such as cracked casing or loose connections. Regularly conduct communication testing to ensure that the module transmits and receives data correctly. ABB frequently releases firmware updates for its products, and maintaining firmware updates for ABB 110 TAS.580.0540G00 is crucial. These updates may include error fixes, performance improvements, and enhanced compatibility. Carefully follow ABB’s official firmware update guidelines to avoid any issues during the update process. By following these installation and maintenance practices, you can ensure the long-term reliable operation of ABB 110 TAS.580.0540G00 in your industrial control system.

Other ABB product models:

ABB 3AUA0000036521

ABB 3AUA0000110430

ABB 3BDS005799R1 PM665

ABB 3BHB003688R0101

ABB 3BHB003688R0101

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689 3BHB003688R0101

ABB 3BHB005243R0105

ABB 3BHB005243R0106 KUC755AE106

ABB 3BHB005243R0117

ABB 3BHB005245R0101

ABB 3BHB005922R0001

ABB 3BHB006309R0001

ABB 3BHB006338R0001

ABB 3BHB006714R0217 SYN 5201a-Z.V217

ABB 3BHB006715R0277

ABB 3BHB007030R0102 UFC760BE102

ABB 3BHB012961R0002

ABB 3BHB015651P0001

ABB 3BHB015651P0001

ABB 3BHB015651P0001

ABB 3BHB015651P0001

ABB 3BHB030310R0001

ABB 3BHB043807R0001

ABB 3BHB043808R0001

ABB 3BHE003604R0102

ABB 3BHE003604R0106

ABB 3BHE004573R0142

ABB 3BHE006373R0101

ABB 3BHE006412R0101

ABB 3BHE009681R0101

ABB 3BHE014377R0001 PVD164

ABB 3BHE017628R0002 PPD115A02 SG579989013

ABB 3BHE022293R0101

ABB 3BHE022293R0101

ABB 3BHE022294R0101 GFD233

ABB 3BHE023784R0001

ABB 3BHE024313R0101 KSD211A101

ABB 3BHE024577R0101

ABB 3BHE024577R0101 11790750105 PPC907BE

ABB 3BHE024747R0101

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626