Description

Real-World Use & Application Scenarios

The ABB 110 TAS.580.0540G00 power supply unit is widely used in industrial automation and control systems where reliable and stable power delivery is crucial. It is ideal for applications such as distributed control systems (DCS), programmable logic controllers (PLC), safety instrumented systems (SIS), and other industrial control equipment requiring a consistent 24V DC power source.

Industries such as manufacturing, energy, oil and gas, chemical processing, and utilities deploy this power supply unit to ensure smooth operation of critical control panels and devices. The unit’s ability to maintain voltage stability under fluctuating input conditions makes it indispensable in environments where power quality directly affects system reliability and uptime.

Product Introduction & Positioning

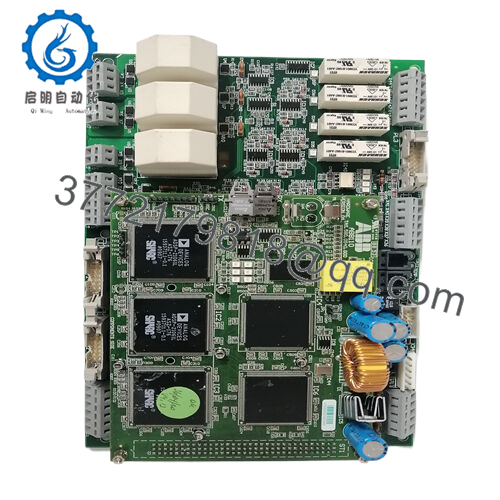

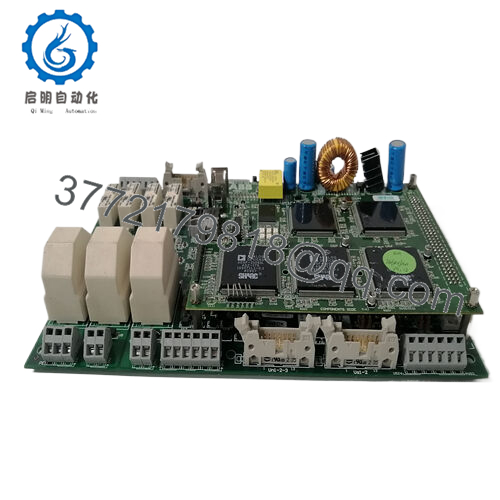

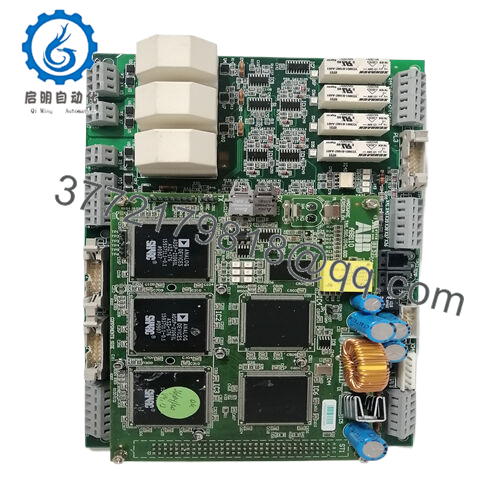

The ABB 110 TAS.580.0540G00 is a compact and efficient power supply module designed to convert 100-240V AC input to a stable 24V DC output with a power output capacity of 40W. It is engineered to meet the high demands of industrial control architectures, delivering reliable power with over 90% efficiency.

Positioned as a standard power supply unit within ABB’s control platforms, it supports a broad range of automation system components, ensuring consistent voltage delivery under diverse load conditions. Its design adheres to industrial safety and electromagnetic compatibility standards, making it suitable for integration into various control cabinets and rack systems.

Key Technical Features & Functional Benefits

The ABB 110 TAS.580.0540G00 power supply unit supports an input voltage range of 100-240V AC, facilitating wide compatibility with international power standards. With an output voltage of 24V DC and a power rating of 40W, it is perfectly suited for supplying power to multiple low-voltage industrial devices and control modules.

The unit offers high efficiency exceeding 90%, reducing heat generation and energy consumption for cost-effective operation. Its compact size (approximately 100 mm x 150 mm x 40 mm) and lightweight construction (1.2 kg) simplify installation and integration in space-constrained panels.

Operating reliably in ambient temperatures ranging from -20°C to +60°C, the module ensures stable performance in various industrial environments. It also incorporates protective features such as overvoltage and short circuit protection, enhancing system safety and durability.

- ABB110 TAS.580.0540G00

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 110 TAS.580.0540G00 |

| Brand | ABB |

| Product Type | Power Supply Unit |

| Input Voltage | 100-240 V AC |

| Output Voltage | 24 V DC |

| Power Output | 40 W |

| Efficiency | >90% |

| Operating Temperature | -20°C to +60°C |

| Dimensions (L x W x H) | 100 mm x 150 mm x 40 mm |

| Weight | Approx. 1.2 kg |

| Protection Features | Overvoltage, Short Circuit |

Related Modules or Compatible Units

PM866-2 – Industrial controller module requiring stable 24V power input.

PU519 – Real-time accelerator enhancing system processing with regulated power.

DO810 – Digital output module compatible with ABB power supplies.

REG216 – Numerical generator protection relay operating within the same control architecture.

IDPG 940128102 – Digital signal processing module dependent on steady power supply.

Installation Notes & Maintenance Best Practices

Installation should ensure proper ventilation around the ABB 110 TAS.580.0540G00 to maintain thermal balance and prevent overheating. Secure mounting and appropriate cable management following ABB guidelines protect against mechanical stress and interference.

Routine maintenance involves periodic visual inspection for dust or damage, verification of output voltage and current, and checking for firmware or regulatory updates as applicable. Protective features should be tested during scheduled maintenance to ensure operational safety.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626