Description

What This Product Solves

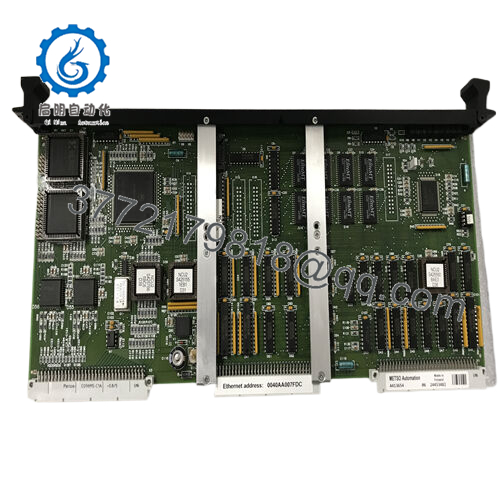

In process control systems where high-density analog signals from field sensors demand unyielding isolation to dodge measurement drift or false alarms in EMI-laden setups, the Metso A413654 (likely an NCU2 or similar network/CPU unit module) delivers a dependable backbone for engineers frustrated by integration silos or fault propagation in legacy DCS architectures. Imagine a pulp digester control loop where unisolated voltage inputs from multiple probes skew temperature profiles, triggering overcooking and batch rejects, or a flotation circuit in mining where channel crosstalk from shared grounds corrupts pH readings, leading to reagent imbalances and yield drops—these pain points often root in modules that can’t handle networked CPU tasks or I/O buffering amid ground potentials in cabinets. This NCU2 network control unit module counters them by managing up to 16 analog/digital channels with galvanic isolation up to 1500 V, incorporating diagnostic relays for line faults and Modbus/Profibus for seamless PLC syncing, ensuring your data flows cleanly for precise control without the vulnerabilities of non-networked designs.

It gains traction in industrial automation sectors like pulp and paper or mineral processing, where high reliability in networked I/O coordination underpins ISO 9001 compliance and minimizes downtime in continuous operations. The Metso A413654 slots into Metso’s Neles or Valmet PLC nodes (e.g., DAMATIC or DNA systems), embracing modular redundancy for failover under 100 ms, so a network glitch doesn’t cascade into halts. For those scaling older Valmet footprints, it bridges without reconfiguration hassles, accommodating mixed analog/digital sources while boosting fault tolerance against transients up to 250 V in vibration-prone enclosures. In expansive process control networks, its robust NCU2 design and -20 to +60°C envelope shrug off dust or humidity, letting you extend cabling without fidelity loss. By prioritizing networked buffering and diagnostic depth, the Metso A413654 anchors system stability, empowering tighter trending and predictive management that aligns with your goals for resilient, data-driven automation without the drag of frequent network verifications in EMI-prone landscapes.

When auditing networked modules for rugged architectures, the Metso A413654 merits a look for its CPU integration and channel versatility, providing the coordination reliability that underpins efficient oversight in vibration-heavy or humid environments.

How the Product Works & Fits into a System

The Metso A413654 (NCU2 module) functions as a network control unit in the core I/O layer of Metso’s Neles/Valmet distributed control systems, buffering and distributing analog/digital signals from field devices to PLC processors via a high-speed bus. It occupies a single backplane slot in PLC nodes (e.g., DAMATIC cabinets), where it handles up to 16 mixed channels with 1500 V isolation to shield against noise, supporting optional HART overlay for polling device status over loops without disrupting flow. This enables integration with asset tools, where HART bursts trigger queries during scans.

- A413654

- A413654

Power-sourced from the node at 24 V DC, it communicates status via the PLC bus, with redundancy wiring for quick handover on faults. It meshes with output modules like AO4C for closed-loop control, handling scan rates down to 100 ms per channel while complying with Profibus for hybrid networks. Onboard diagnostics scan for breaks or overrange, routing alerts to consoles, and the NCU2’s design adds EMI filtering for cleaner sync. Nestled between fields and logic, the Metso A413654 streamlines architecture by consolidating buffering in nodes, where screw terminals ease wiring and shielding preserves accuracy in backs, building a tough setup that scales with Ethernet/IP sans reworks.

| Specification | Details |

|---|---|

| Model Number | A413654 (NCU2) |

| Brand | Metso (Neles/Valmet) |

| Type | Network Control Unit Module (16-ch Mixed I/O) |

| Input Voltage | 24 V DC (node-supplied) |

| Operating Temp Range | -20°C to +60°C |

| Mounting Style | Backplane Slot (PLC Node) |

| Dimensions | 35 x 140 x 120 mm (W x H x D) |

| Weight | 0.25 kg |

| Interface/Bus | PLC Bus, Modbus/Profibus |

| Compliance | CE, ISO 9001, RoHS |

| Supported Protocols | Profibus, Modbus, HART |

| Typical Power Draw | 6 W (full load) |

Real-World Benefits

Opting for the Metso A413654 means harnessing a module engineered for rock-solid buffering, sustaining 0.1% accuracy across swings to nix the tweaks that gum up loops and slacken responses in load-shifting tasks, freeing your crew for tweaks over fixes and trimming waste from off-kilter readings like fiber density or slurry pH. This grip aids upkeep too, with fault flags that spot channel snags early for proactive swaps, often halving intervention time in tracked fleets.

The slot fit cuts scaling load as well—bus mapping skips reroutes, easing rack packs and shifting engineering from wiring woes to logic polish. Built for field grit, it tanks 250 V hits and 95% dampness, with coatings that fend off dust for enduring sync, keeping your Metso setup supple to process pivots with light steps.

In pulp refiners, the Metso A413654 buffers temperature and pressure signals from digester probes, where isolated channels brave steamy, fibrous airs to hold uptime and evenness in non-stop runs.

Mining SAG mills tap it for load cell inputs, with quick-scan filters for tweaks in dusty, shaky spots, lifting solid pulls.

For effluent pH control, this module ingests turbidity analogs, tackling wet, chem-rich vibes with tough pairs that back enclosure adds in big I/O webs.

Compatible or Alternative Products

A413659 – Enhanced NCU variant with 32 channels for higher-density networked I/O in expanded PLC nodes.

A413665 – CPU-focused alternative for core processing in Valmet DAMATIC systems.

D201136 – Analog input handler for balanced I/O in Neles architectures.

A413600 – Digital output module for hybrid signaling in batch control.

IOP341 – High-density input alternative for denser racks.

Neles ND9000 – Compatible PLC node for housing the A413654 in rack builds.

Setup Notes & Maintenance Insights

Before fitting the Metso A413654, check PLC node sync with Valmet/Neles firmware (5.x+ for bus support), and snug terminals at 0.5 Nm to fight shakes—too tight snaps traces. Peg channel loads below 16 mA per input to dodge drops, and steer wires from power by 200 mm to mute noise, key in EMI cabinets near motors.

Keep it sharp with quarterly terminal peeks for snugness and clean, as grit dulls signals in pulpy or dusty spots. Tap diagnostic pings monthly via PLC screen to eye channel trends, noting overrange for fuse swaps. Run yearly load sims at 4-20 mA to check linearity, and grab firmware patches from Metso for better EMI or security. This keeps tweaks low, fitting your PM flow to hold signal flow sans node halts.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626