Description

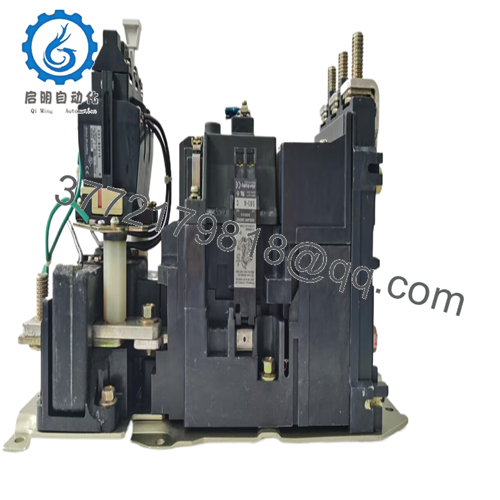

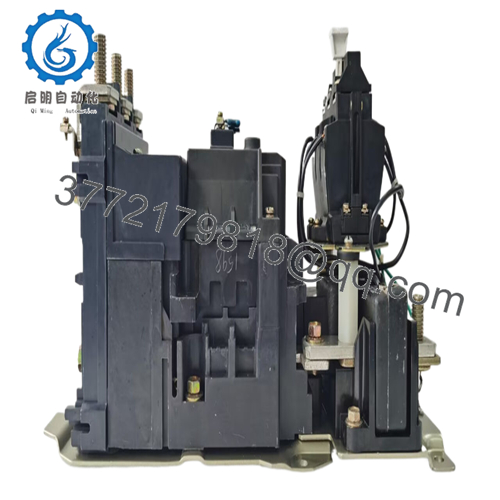

In the realm of industrial automation, managing high-power motor starts without risking thermal overloads, voltage sags, or unexpected trips is a core concern for engineers overseeing pumps, compressors, or conveyor lines in manufacturing plants. The Allen-Bradley 509-FOD steps up as a NEMA full-voltage non-reversing starter, delivering precise control for three-phase motors up to 270 amps while embedding overload protection to safeguard against burnout during peak loads. This becomes essential in process control environments where a motor failure could halt production—think a water treatment facility where sludge pumps run continuously; without reliable starting and thermal monitoring, you’d face frequent resets, energy waste, or even equipment damage from inrush currents exceeding safe limits. By prioritizing high reliability in I/O signal handling for start/stop commands, the Allen-Bradley 509-FOD ensures system stability, allowing seamless integration into PLC-driven setups without the need for custom relays or additional safeguards.

Engineers value the Allen-Bradley 509-FOD for its straightforward approach to modular integration, fitting into broader automation strategies where downtime from motor faults directly impacts throughput. It’s particularly crucial in scenarios demanding quick response to process changes, like batch mixing in food processing, where imprecise overload detection might lead to quality inconsistencies or safety lapses. With built-in eutectic alloy overload relays, it trips accurately on sustained overcurrents while resetting reliably after cooldown, aligning with goals of enhanced diagnostics and reduced maintenance calls. Keywords such as “industrial automation,” “process control,” “I/O signal,” and “high reliability” capture its essence—the Allen-Bradley 509-FOD bridges the gap between control logic and field devices, supporting fault-tolerant operations that keep lines moving in demanding, 24/7 environments.

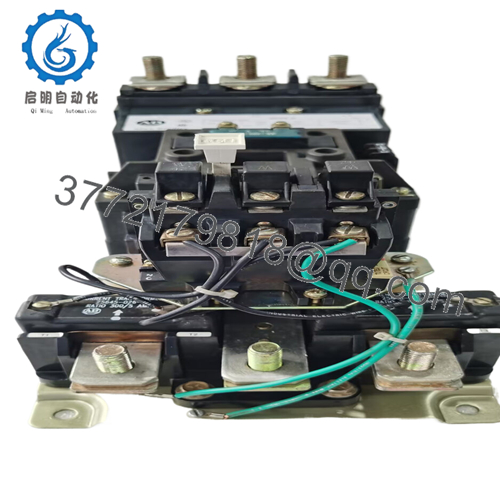

The Allen-Bradley 509-FOD operates at the motor control center level within the automation stack, receiving discrete I/O signals from a PLC like the ControlLogix series to energize its contactor coils, initiating full-voltage starts for three-phase induction motors. It connects via standard NEMA wiring to the power bus, with auxiliary contacts for feedback to the controller—confirming run status or fault conditions—while the overload relay monitors phase currents independently, interrupting power if imbalances exceed set thresholds. This positioning makes it a natural extension of backplane systems or remote I/O racks, where it handles the heavy lifting of power distribution without taxing upstream processors.

- 509 FOD XXX

In a typical setup, the starter integrates with protocols like Ethernet/IP for networked monitoring, allowing the PLC to poll overload status in real time and log events for predictive analytics. Its non-reversing design ensures unidirectional operation, ideal for applications avoiding bidirectional torque, and supports add-on accessories like control transformers for coil isolation. Diagnostics come via bimetallic elements in the overload relay, which bend under heat to open contacts, providing visible trip indications without electronics that could fail in harsh conditions. For instance, in a conveyor system, the Allen-Bradley 509-FOD might receive a start pulse from the PLC, ramp the motor to speed, and signal back via auxiliary outputs, all while maintaining arc suppression for safe de-energization. This user-centric flow reduces wiring complexity and enhances compatibility with variable frequency drives for hybrid control, keeping the focus on reliable performance rather than constant reconfiguration.

| Specification | Details |

|---|---|

| Model Number | 509-FOD |

| Brand | Allen-Bradley (Rockwell Automation) |

| Type | NEMA Full-Voltage Non-Reversing Starter |

| Input Voltage | 110-120 VAC 50/60 Hz (coil) |

| Operating Temp Range | -20 to +60°C |

| Mounting Style | Panel or DIN rail adaptable |

| Dimensions | 20″ x 16″ x 12″ (approx. 508mm x 406mm x 305mm) |

| Weight | 31.5 kg |

| Interface/Bus | NEMA 3R auxiliary contacts |

| Compliance | UL 508, CSA C22.2, NEMA ICS 2 |

| Supported Protocols | Ethernet/IP (via PLC integration) |

| Typical Power Draw | 270 A full load (3-phase 600V) |

Deploying the Allen-Bradley 509-FOD brings immediate value through its engineered resilience, ensuring long-term performance by protecting motors from thermal stress that shortens lifespan in cyclic operations. In real terms, this means fewer nuisance trips during startup surges, allowing pumps to accelerate smoothly and maintain process control without dipping into backup systems—ultimately slashing energy costs tied to inefficient restarts. The eutectic alloy relay’s trip class 10/20 adjustability fine-tunes protection to match load profiles, preventing overprotection that idles equipment prematurely while catching true faults before they escalate.

This starter also boosts maintenance efficiency, as its manual reset button and visible status flags enable on-the-spot troubleshooting, cutting diagnostic time in crowded panels and reducing engineering overhead for field teams. By integrating cleanly with Allen-Bradley ecosystems, it supports remote monitoring via Connected Enterprise tools, where overload data feeds into analytics for trend-based upkeep, minimizing unplanned outages. For facilities chasing high reliability, the Allen-Bradley 509-FOD transforms motor control from a potential bottleneck into a predictable asset, fostering consistent throughput and compliance with standards like NFPA 70E for arc flash safety.

In water and wastewater treatment plants, the Allen-Bradley 509-FOD powers aeration blowers, handling high-inertia starts under humid conditions while its overload relay ensures critical system uptime by tripping only on genuine overcurrents, avoiding disruptions to filtration processes. This setup thrives in environments with variable loads, delivering robust I/O signal response for PLC-coordinated sequencing.

Pulp and paper mills rely on the Allen-Bradley 509-FOD for roller drives in paper machines, where fast data cycles from sensors trigger starts amid dusty, high-vibration settings—its NEMA size 5 rating maintains process control integrity, preventing web breaks that halt production lines.

Mining operations deploy the Allen-Bradley 509-FOD in conveyor starters, enduring abrasive dust and shock loads to sustain continuous material flow; the starter’s high reliability safeguards against motor stalls, optimizing haulage efficiency in remote, harsh process control environments.

509-FOD-A2N – Upgraded variant with E1 Plus solid-state overload for digital trip curves in advanced diagnostics.

509-ROD – Reversing starter counterpart for bidirectional motor applications like hoists.

509-FOD-D02 – Compact size 2 version for lighter loads up to 45 A in space-limited panels.

500-COD – IEC-rated alternative for global compliance in full-voltage setups.

193-EC4 – E1 Plus overload relay add-on for retrofitting to legacy 509 series.

509-ACO – Across-the-line starter with electronic overload for precision current sensing.

1492-J – Interface module for PLC I/O integration with 509 starters.

194R-N – NEMA contactor for custom non-reversing builds, size 5 equivalent.

When preparing to install the Allen-Bradley 509-FOD, double-check motor full-load amps against the overload dial settings (60-300 A range) to avoid mismatches, and confirm panel space accommodates the size 5 footprint with at least 6 inches of clearance for heat dissipation. Verify coil voltage matches your control circuit—120 VAC typical—and test grounding continuity to chassis to comply with NEC requirements, using a megger for insulation resistance over 1 MΩ. If pairing with a PLC, map auxiliary contacts to discrete inputs for status feedback, and ensure enclosure ventilation prevents ambient temps exceeding 60°C.

For maintenance, inspect overload heaters quarterly for discoloration indicating wear, recalibrating trip points with a clamp meter to within 5% of rated current, especially in dusty sites where buildup can skew readings. Annually, during shutdowns, cycle the contactor 10 times under no-load to check for pitting on contacts, cleaning with a fiber brush if needed, and log reset frequency to spot emerging patterns. These checks, grounded in NEMA ICS 2 guidelines, keep the Allen-Bradley 509-FOD dependable without overhauling routines, letting you address issues before they compound.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626