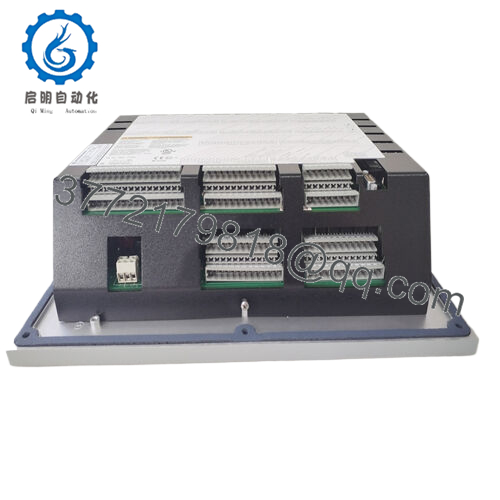

Description

Product Model: 9907-1183

Product Brand: Woodward

Product Series: 505E / Enhanced Turbine Control

Product Features:

- Designed for steam turbine control, with support for extraction/admission control in the 505E series

- Accepts 18–32 V DC power input

- Two serial communication ports with Modbus (ASCII or RTU) support

- Features password-protected programming, zero-speed detection, and robust HMI interface for control and diagnostics

Technical Features & Benefits

In the world of steam turbine control, the 9907-1183 occupies a mature but still relevant niche: it is a digital governor/controller in the Woodward 505E series, designed specifically for steam turbines, turboexpanders, or extract/admission turbine rigs.

At its core, the 9907-1183 handles closed-loop speed control, extraction/admission regulation, and turbine protection. Its embedded logic applies control algorithms (PID/regulation, ratio/limiter, etc.) to modulate valve or control element motion based on feedback signals.

One standout feature is its dual serial communication ports supporting Modbus (ASCII or RTU). This allows integration with plant DCS/SCADA systems, remote monitoring, or parameter updates. The interface gives operators real-time visibility into operating parameters, alarms, and diagnostics.

The power supply pivot is also interesting: 9907-1183 expects 18–32 VDC, which matches many modern turbine control racks. That simplifies retrofits into existing 24 V control busses.

On the human-machine side, it includes a built-in HMI (Human Machine Interface) / control panel arrangement that allows on-site monitoring, status reading, and some level of configuration without needing a PC. Password protection is built in to guard against unauthorized changes.

Protection logic is comprehensive: the 9907-1183 supports zero speed detection, safety interlocks, over/under speed, and other turbine health checks inherent to the 505E platform.

- 9907-1183

From a benefits perspective:

- Upgrading to 9907-1183 gives digital control accuracy and flexibility versus older analog governors

- Its built-in communications simplify integration with supervisory systems

- Because it’s designed for turbine control, its algorithms are specialized for steam extraction/admission and managing multi-valve systems

- The system’s interlocks and safety logic reduce risks of overspeed or runaway events

In field experience, operators often report smoother transitions during load changes and better fault visibility after moving to a 505E controller like the 9907-1183. The improved diagnostics help reduce mean time to repair (MTTR) during failures.

Product Role & System Integration

Let’s examine how the 9907-1183 fits into a broader turbine control architecture.

In a typical steam turbine installation, you have the following functional blocks: speed sensing, control logic, extraction/admission valves, load control, and communication or supervisory oversight. The 9907-1183 acts as the control logic and governor unit. It ingests speed feedback (from a pickup or sensor), inputs from pressure or flow sensors (for extraction or admission control), and outputs actuator commands (to valves or servo systems) to maintain or adjust output.

Specifically, in single-extraction or admission turbines, the 9907-1183 can be configured to manage an extraction valve or control path dynamically, including ratio / limiter, overshoot avoidance, and valve position control logic. It can also supply reference signals or mode commands from upstream DCS via Modbus to shift operational modes, trim, or other adjustments.

When integrated into a larger power plant, 9907-1183 often serves alongside generator control modules (e.g. DC exciters, generator governors) and protective systems. The controller may also supply alarm and status signals to SCADA. The dual Modbus ports allow linking to redundant or separate supervisory buses.

Because many installations already have 24 V DC control busses, the 18–32 V input simplifies deployment: the 9907-1183 can tap into the same supply rails without requiring specialized power converters.

From a retrofit perspective, you might replace an older 505 or other governor unit with 9907-1183, especially in systems with limited physical space but needing advanced features (digital control, communication). Many vendors advertise this replacement path.

Finally, note that the 505E designation implies the controller is designed specifically for turbine applications and is not a generic speed regulator. Its algorithms, interlocks, valve management logics, and safety features are tuned for that role.

Installation & Maintenance Insights

When installing or servicing 9907-1183, attention to detail ensures reliable operation. Here are field-tested tips and caveats.

Mounting & Environment

Place the controller in a clean, ventilated control cabinet protected from extreme vibration, temperature swings, or condensation. While the unit is rugged, it benefits from ambient temperature regulation.

Power Wiring

Use stable DC supply wiring sized properly to avoid voltage drop. The allowable input range (18–32 VDC) gives some headroom, but under-voltage or transient dip can upset internal logic. Use fusing or surge suppression as needed.

Sensor and Signal Wiring

Speed sensors, pressure sensors, or other instrumentation should use shielded, twisted pair cabling. Terminate shields at one end, maintain consistent grounding, and keep analog wiring separate from power or high-current runs.

Because the 9907-1183 often interfaces with multiple valves (extraction/admission), ensure valve position feedback loops, position sensors, or servo feedback are cabled securely and calibrated correctly. Misalignment or drift in valve position feedback can degrade controller stability.

Commissioning Steps

- Power up and verify that the HMI / display shows correct speed, diagnostics, and no fault flags

- Configure operational parameters: PID gains, valve limits, modes (speed, load, extraction control)

- Test closed-loop operation under light load, gradually increasing to full load to tune response

- Simulate failure modes (e.g. sensor fault, valve jam) to confirm fallback or protective logic

- Verify Modbus communication to SCADA or DCS (read/write registers)

- Exercise transitions (e.g. from speed control to extraction control) and ensure smooth behavior

Maintenance & Diagnostics

- Inspect and tighten terminal connections regularly

- Clean dust or residues from the cabinet and ensure airflow

- Monitor logs or alarm history via HMI or Modbus, looking for repeated trips, warnings, or drift

- Periodically re-calibrate sensors and compare speed readings with external references

- Keep a spare 9907-1183 configured with your parameter set so swap-outs are fast

Repair / Spare Strategy

Given that many listings treat 9907-1183 as a specialized, legacy unit, maintain a hot spare. When replacing, backup firmware, parameter files, and configuration before removal. If sending for repair, include test reports, logs, and any observed failure behavior. Many distributors offer refurbishment or repair services.

Because the 9907-1183 is integral to turbine safety and control, any fault or misbehavior should be handled by experienced turbine/control engineers, not as a generic control card swap.

Technical Specifications Table

Below is a specification summary for 9907-1183 drawn from available sources. Because official full datasheets are not public, these are the best-known values; use them as guidelines and verify against actual hardware.

| Parameter | Value / Description |

|---|---|

| Module Type | 505E Steam Turbine Digital Governor / Control |

| Power Supply | 18–32 VDC |

| Communication | 2 × serial ports, Modbus (ASCII or RTU) |

| Dimensions | Approx. 14 × 11 × 4 in (356 × 279 × 102 mm) |

| Ambient Operating | –25 °C to +65 °C recommended |

| Features | Password-protected programming, zero speed detection |

| Application Type | Steam turbines, turboexpanders, extraction/admission control |

| Housing / Protection | Can be outfitted with NEMA 4X case (optional) |

Note: Some distributor sources claim extended temperature ranges or IP67 housing; these should be verified with your unit’s build label.

Related Models & Alternatives

Here are some sibling or related units you may encounter when working with 9907-1183 or planning replacements/upgrades:

- 9907-1183 Rev A / Enhanced 505 — some listings note “REV A” versions, possibly with firmware or hardware improvements over earlier builds

- Other 505E series units (9907-164, 9907-167, etc.) — alternate or newer steam turbine controllers in the same product family

- 505D / 505 Basic — earlier or simpler turbine control variants; if flexibility is not critical, these may be alternatives

- Modern digital turbine controllers / microprocessor governors — for future upgrades with integrated network, diagnostics, and extended features

- PLC / DCS-based turbine control modules — embedded control systems replacing discrete turbine controllers

When considering a replacement, ensure feature parity (modbus ports, I/O type, extraction logic, HMI features) to avoid custom redesign.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626