Description

Product Model: 8440-2028

Product Brand: Woodward

Product Series: IKD 1 / Digital I/O Expansion

Product Features:

- 8 configurable discrete inputs (galvanically isolated) and 8 Form-C relay outputs

- Communicates via CAN bus to host controller (e.g. easYgen, GCP, XPQ)

- Operates on 12/24 V DC (6–36 V DC range) with low intrinsic consumption (~3 W)

- Broad ambient specs (-20 °C to 70 °C operating, storage down to –40 °C) and robust isolation design

- 8440-2028

- 8440-2028

Applications & Industry Fit

In modern generator sets and power control applications, there’s often a need to extend the number of digital inputs and relay outputs beyond what the base control module can handle. That’s exactly where 8440-2028 comes in. In systems using Woodward’s easYgen, GCP, or XPQ controllers equipped with the IKD interface option (SC09/SC10), you’d deploy one or more 8440-2028 modules to handle extra alarm inputs, interlocks, or relay outputs without redesigning the controller core.

For example, in a medium-size genset installation, the base controller may already monitor critical parameters (voltage, current, speed, temperature). But as the plant evolves, you might add additional discrete sensors—breaker status, external alarms, cooling system faults, fuel pump interlocks. Instead of redesigning the control system, the 8440-2028 can be mounted in the control rack (or DIN rail) and wired to those extra sensors and relay actuators. The module relays digital input status to the controller over CAN bus and receives commands to energize relays appropriately.

Another scenario is retrofits: you may have installed a new control unit that lacks enough I/O for your field wiring. You can introduce 8440-2028 modules to absorb that growth, retaining much of your existing wiring and minimizing system disruption.

In industrial settings—such as backup power installations, remote plants, or microgrid controllers—the module enables robust expansion of alarm, interlock, or control circuitry without bloating the base control module.

Because the 8440-2028 uses galvanic isolation on the discrete inputs and isolates the relay contacts, it helps protect against noise, ground loops, or interference in harsh industrial electrical environments.

The 8440-2028 is also used in nuclear plant controls (as one listing suggests) and other safety-intensive systems, where extra discrete alarms and relay control are needed (PLC-module listing mentions “nuclear power plants”).

Thus, wherever you need robust discrete I/O expansion tied into a CAN-based controller architecture, 8440-2028 is a compelling module.

Product Role & System Integration

At its essence, 8440-2028 functions as a Digital I/O Expansion Module (or “Discrete I/O Expansion Board”) in Woodward’s IKD 1 family. It’s not a standalone controller—instead, it acts as a satellite—receiving digital input status and executing output relay commands under direction of the main controller.

Connection to the host is via CAN bus, with galvanic isolation to protect communication integrity. The module’s discrete inputs are galvanically isolated and accept 12/24 V DC (6–32 V range) signals, typically originating from sensors, switches, or alarm contacts. On the output side, it offers up to 8 Form C (changeover) relay contacts (potential-free), which can switch loads under general purpose (GP) or pilot duty ratings.

Inside the overall system, the 8440-2028 is addressed by the controller (e.g. easYgen) via a relay manager or alarm module. Discrete input signals from the IKD 1 are visible to the control logic (for alarm classes, logic interlocks, or indication), and the control logic may send commands to the module to actuate relays over the same CAN link.

Because the module is modular, you can stack multiple 8440-2028 modules in a system (subject to controller limits) to extend I/O capacity. The module’s firmware and addressing scheme must match the controller’s configuration (the controller will assign ID, alarm classes, delays, input logic, etc.).

When commissioning, the controller’s configuration tool (or relay manager) communicates with the 8440-2028 to read inputs, program delays, name alarms, set NO/NC logic, and control relays. In many cases, installers will use a PC configuration cable (DPC, RS-232 or USB) connected directly to the 8440-2028 for initial parameter setup.

Thus, the module sits in the signal path between field wiring and the controller logic layer, serving as a discrete I/O bridge in distributed control architectures.

Technical Features & Benefits

Let’s break down the standout features of 8440-2028 and why engineers still incorporate it in modern systems.

Galvanic Isolation & Noise Immunity

Its discrete input channels are galvanically isolated, which helps reduce interference from ground loops or electrical noise—a must in industrial settings. The relay outputs are potential-free (Form C), further isolating load circuits from the module’s internal electronics.

Wide Voltage Range & Low Consumption

Though nominally powered at 12/24 V DC, the module supports a broader input range of 6 to 36 V DC. Its intrinsic consumption is modest—max ~3 W—minimizing thermal load in control cabinets.

Relay Output Capacity & Ratings

It offers up to 8 Form C relays. For general purpose switching (GP), it handles up to 2.00 A at 250 VAC, or 2.00 A at 24 VDC, and reduced ratings at higher voltages. For pilot duty (PD), the spec is lower (e.g. 1.00 A at 24 VDC). These ratings are sufficient for typical alarm, interlock, or control circuits (e.g. contactors, indicator lamps).

Configurable Inputs & Delays

Each discrete input is configurable (alarm class, NO/NC logic) and can be assigned a time delay before it’s passed onto the controller. This is useful in filtering transients or preventing nuisance alarms. You can also name and classify each input for clarity in the controller’s interface.

Service & Configuration Interfaces

The board supports a service interface (RS-232 or USB depending on variant) for initial setup or parameter backup/restore. The module’s firmware and configuration can be modified before wiring, simplifying installation in the field.

Robust Environmental Specifications

It’s rated for operation across –20 °C to 70 °C. In storage, it can survive –40 °C to 85 °C. It handles up to 95% humidity (non-condensing) and meets EMC/CE standards. Insulation and isolation (100 V continuous, 1,000 V for test) are built in.

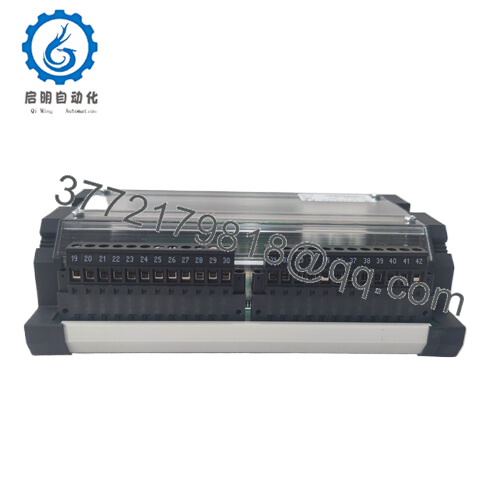

Modular Mounting & Footprint

Physically, the module mounts via a DIN-rail snap or bracket (extrusion profile Um 122) and dimensions of ~168 × 128 × 51 mm. Weight is roughly 360 g. Its screw/plug terminal blocks are rated for up to 2.5 mm² wiring.

CAN Bus Integration & Expandability

The module communicates over CAN bus to the host controller. Digital input status is pushed upstream, and the controller may send output commands for relay control. Because it uses standard communication protocols, multiple 8440-2028 modules can coexist on the same bus (with unique addresses) to scale I/O count.

In practice, these features mean the 8440-2028 is a reliable, noise-resistant, and flexible expansion module for discrete I/O in generator control and industrial automation systems.

Technical Specifications Table

| Parameter | Value / Description |

|---|---|

| Power Supply | 12/24 V DC (6.0 – 36.0 V DC) |

| Intrinsic Consumption | Max ~ 3 W |

| Operating Temperature | –20 °C to 70 °C |

| Storage Temperature | –40 °C to 85 °C |

| Ambient Humidity | Up to 95%, non-condensing |

| Discrete Inputs | 8 galvanically isolated inputs, rated 12/24 V (6–32 V) |

| Input Resistance | ~6.8 kΩ |

| Relay Outputs | 8 Form C (potential-free) relays |

| GP Switching Ratings | 2.00 A @ 250 VAC; 2.00 A @ 24 VDC; 0.36 A @ 125 VDC; 0.18 A @ 250 VDC |

| PD Switching Ratings | 1.00 A @ 24 VDC; 0.22 A @ 125 VDC; 0.10 A @ 250 VDC |

| Interface | CAN bus (galvanically isolated) + Service (RS-232 / USB) |

| Insulation | 100 V continuous; 1,000 V test (≤5s) |

| Mounting | DIN-rail snap or C-profile; approx. 168 × 128 × 51 mm |

| Weight | ~360 g |

| Terminals | Screw/plug connectors, up to 2.5 mm² wiring |

| Certifications / Listings | UL / cUL, CE, tested to relevant EN guidelines |

Installation & Maintenance Insights

To deploy 8440-2028 smoothly and keep it reliable over years, here are field-proven tips and cautions.

Mounting & Vibration Considerations

Although the module mounts on DIN-rail, in high-vibration environments (e.g. engine rooms), avoid mounting it directly on heavy mechanical panels. The manual suggests using a vibration absorber if mounting in engine switch boxes. Be sure the module is secured firmly and avoid loose wiring that could fatigue connectors.

Wiring Best Practices

Keep discrete input wiring (12/24 V sensors, switches) separate from high-current lines or power cables to minimize interference. Use twisted pair + shielding when possible, with shield grounded at one point (typically at the module end) to prevent ground loops. Relay output wiring should be isolated and kept away from sensitive signal paths.

Ensure that discrete input logic (NO vs NC) and delays are configured properly in the controller to avoid misinterpretation of transient signals. Because each input has programmable delay logic, you can filter noisy transitions or chattering contacts without hardware modifications.

CAN Bus Layout & Termination

CAN wiring must be properly terminated and routed. Use consistent cable impedance, correct termination resistors, and minimize stub lengths. The module’s CAN interface is galvanically isolated, so ensure proper grounding and referencing in your bus topology.

Commissioning & Diagnostics

Before energizing field circuits, test communication with the controller and check that the 8440-2028 responds as expected (input status, relay command feedback). Use the service interface (RS-232 or USB) to read configuration, backup parameters, or diagnose faults. Monitor error or warning flags in the controller on the discrete I/O interface.

During commissioning, inject test signals (simulate discrete input ON/OFF) to verify correct response from the control logic and that relay commands execute as expected. Validate each input’s configured delay and alarm assignment.

Maintenance & Periodic Checks

Periodically inspect terminal blocks for corrosion or loose screws. Confirm relay contacts are switching reliably and not stuck. Check wiring insulation integrity. Clean dust and debris; ensure ventilation and ambient temperatures remain within spec. Observe error logs in the controller for input bounce, CAN errors, or relay faults—these may indicate wiring degradation.

Because the module’s electronics are relatively passive (low internal heating), lifespan tends to be long. However, over time connectors or contacts may degrade—so maintaining a spare 8440-2028 is wise for fast replacement in critical installations.

Firmware & Compatibility

If upgrades exist, ensure that the module firmware is compatible with the controller’s version. Some upgrades may fix CAN communications, error reporting, or input logic quirks. Always test new firmware in a staging environment before applying in production.

Related Models & Migration Options

Here are sibling or alternate modules you might encounter, or consider when planning upgrades:

- 8440-2116 (IKD1M variant) — a version of the IKD expansion module preconfigured for easYgen 2000/3000/XT and DTSC series, though hardware is similar to 8440-2028.

- SC09 / SC10 Option Cards — these are the expansion “slots” or logic options in Woodward controllers that allow connecting IKD modules like 8440-2028.

- GCP / XPQ controllers — the host controllers to which 8440-2028 is typically connected, supporting IKD expansion modules.

- Alternative I/O expansion modules — in non-Woodward systems, there are discrete I/O expansion units (e.g. from PLC vendors) that serve similar roles, though integration wiring is different.

- Redundant I/O modules / failover I/O — for mission-critical plants, redundant discrete I/O modules (dual CAN bus, hot-swap capabilities) may be considered—though the 8440-2028 is not inherently redundant.

When planning upgrades, you may phase out older modules in favor of modules with higher integration, faster communication, or built-in diagnostics. But until then, 8440-2028 is a robust, time-proven choice in the Woodward I/O expansion ecosystem.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626