Description

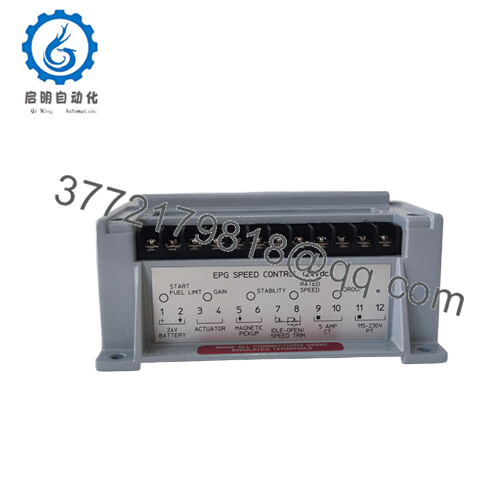

Product Model: 8290-191

Product Brand: Woodward

Product Series: EPG (Electrically Powered Governor)

Product Features:

- 24 V DC droop speed control for diesel prime movers

- Up to ~95 W power consumption; requires ≥ 5 A battery charger

- Compatibility with Woodward actuators 1712/1724 or 512/524

- Wide ambient range (–40 °F to +167 °F) and robust control dynamics

Applications & Industry Context

In many diesel-powered generator sets, industrial engines, or remote prime movers, precise speed control is essential for stable power delivery. The 8290-191 fits in as a compact, electrically driven governor designed to manage engine speed with droop characteristics, especially in applications where hydraulic or mechanical governors are impractical.

You’ll see this model used in medium to large diesel gensets in standby or continuous duty service, in mobile power packs, and in systems where clean, responsive speed regulation is required without auxiliary power sources. Because it’s electrically driven, it suits prime movers that lack mechanical or hydraulic drive paths.

In microgrid or hybrid systems, where multiple modules may need droop sharing, the 8290-191 can serve as a governor that integrates into load sharing schemes. Its droop capability ensures that individual units proportionately share load changes. For systems with variable loads—industrial compressors, pump skids, or small grid tie units—the ability of the 8290-191 to react to load swings is a key advantage.

Field engineers often report that replacing older mechanical governors with EPG modules like the 8290-191 reduces maintenance, simplifies tuning, and reduces lag under transient conditions. In retrofit projects especially, it allows preserving much of the existing wiring and actuator hardware while modernizing the control logic.

Product Role & System Fit

At its core, 8290-191 is an electrically powered speed controller (governor) with droop mode capability. It forms part of the Woodward EPG (Electrically Powered Governor) family. The controller receives engine speed feedback (from a magnetic pickup or proximity sensor), compares it with a reference (setpoint), and drives an actuator to adjust fuel input.

Unlike purely mechanical governors, the EPG design requires no hydraulic or mechanical power supply—making it ideal for engines without extra drive capability or for lightweight systems.

In a system architecture, the 8290-191 typically sits between the speed sensor and the actuator. It may also accept inputs from load sensing accessories (if present) for load sharing coordination. The unit’s switchable dynamics (between stable low-load response and aggressive transient response) allow it to adapt across operating regimes.

Compatibility is a strong point: the 8290-191 is designed to work with actuators such as Woodward’s 1712/1724 or 512/524 models. In many systems, the EPG module can be swapped into existing configurations if the actuator interface matches and wiring is consistent.

Because it supports droop mode, the 8290-191 can also integrate into multi-unit systems that require proportional sharing of load changes. When paired with synchronizers or load sensors, operators can coordinate multiple units more stably.

- 8290-191

Technical Features & Benefits

Let’s zoom into what makes 8290-191 effective and why engineers value it.

Droop Speed Control

The 8290-191 is fundamentally a droop governor: as load increases, speed is allowed to drop proportionally (according to the droop setting). That enables multiple units to share load changes stably.

Supply Voltage & Power Consumption

It is designed for 24 V DC systems, with an operational range from ~20 V to 32 V DC. Its consumption is about 95 W. That implies the battery charging system or voltage bus must provide adequate capacity—typically at least 5 A charge margin.

Actuator Compatibility

The 8290-191 supports common Woodward actuators 1712/1724 or 512/524. This compatibility allows reuse of existing actuator hardware in many installations.

Dual Dynamics & Stability Tuning

The EPG family emphasizes switchable dynamics: one mode for stability at low load, another for fast response to transients. That flexibility helps maintain smooth operation across the engine’s operating envelope.

Load-Sharing Support

Although the 8290-191 is a droop governor, it can work with load sensing accessories or synchronizing modules that help coordinate multiple units. This is key in parallel genset installations.

Ruggedness & Thermal Range

The device is rated for wide ambient temperature operation. For example, –40 °F to +167 °F (–40 °C to ~75 °C), which suits industrial, remote, and varied environments. Its housing and internal electronics are built to handle the stresses in engine compartments.

Start-Fuel Limiting & Smoke Control

One useful feature is start fuel limiting: during engine start, the governor limits fuel injection to prevent overshoot or excessive smoke. That is especially beneficial in diesel engines where startup surges must be contained.

Ease of Integration & Accessory Ecosystem

The unit adheres to standard wiring practices (twisted shielded cable for sensors, short runs, specific wiring guidelines) and integrates into Woodward’s EPG product ecosystem (load sensors, ramp generators, synchronizers).

In real-world experience, operators appreciate that the 8290-191 often reduces drift and tuning issues seen in older mechanical governors, and its dynamic modes make fine tuning of transient vs steady-state response more straightforward.

Installation & Maintenance Insights

Here are best practices, caveats, and tips distilled from field usage and official documentation.

Mounting & Wiring Layout

Mount the unit close to the actuator to minimize wiring length. Use secure fasteners and avoid vibration stress. Wiring to the battery and actuator should be as short as feasible to reduce voltage drop. In the official manual, wiring distance and gauge guidelines are specified. Use twisted, shielded cable for magnetic pickup or sensor lines; ground shields at one end only.

Sensor & Pickup Wiring

For speed input (MPU or proximity sensor), observe correct phasing, shielding, and termination to avoid noise. Use the wiring diagrams in the EPG manual (there is one specifically for models 8290-191 / 192) to layout wiring correctly.

Power Supply & Grounding

Ensure battery or DC bus supply is stable and capable of supporting the ~95 W load plus actuator current. Use fuses or protection in series. Follow grounding protocols to avoid ground loops or interference.

Commissioning & Tuning

- After wiring, verify power-up, sensor reading, and start with safe test speeds.

- Use the governor’s trim potentiometer or configuration to set steady-state frequency offset and droop. The manual mentions about ±2.5 % trim (1 kΩ pot) or ±5 % (2 kΩ pot) settings.

- Observe engine response to load steps and adjust stability/dynamics mode if oscillation or lag occurs.

- Confirm start-fuel limiting works (i.e. engine accelerates cleanly without overshoot).

- Test under full load and transient loads to ensure the 8290-191 maintains control under worst-case conditions.

Periodic Maintenance

- Visually inspect wiring, connectors, and cable insulation integrity

- Check for corrosion or loosened terminals

- Confirm sensor signals still clean and without noise

- Validate control tuning remains optimal (especially after engine overhaul or changes)

- Keep a spare unit and pre-configured settings to allow fast replacement.

Repair & Spare Strategy

Given that some distributors list the 8290-191 as discontinued or surplus, many facilities maintain a hot spare. Ensure the spare matches the firmware or configuration version. Documenting calibration and tuning parameters is essential so you can reinstall quickly.

When repairing, use a certified service center referencing Woodward’s EPG service programs and the warranty options in Manual 82329.

Technical Specifications Table

| Parameter | Value / Description |

|---|---|

| Module Type | Electrically Powered Governor (EPG) module, droop control |

| Supply Voltage | 24 V DC (operational range ~20 V to 32 V) |

| Power Consumption | ~95 W typical |

| Actuator Compatibility | Woodward 1712/1724 or 512/524 actuators |

| Ambient Temperature | –40 °F to +167 °F (approx –40 °C to +75 °C) |

| Control Mode | Droop speed control, with switchable dynamics |

| Start Fuel Limiting | Supported for cleaner startup and prevention of overshoot |

| Load-Sharing Support | Compatible with load-sensing accessories / multiple units |

| Wiring Requirements | Short runs, twisted & shielded cables, proper grounding (manual diagrams) |

| Mounting | Rigid mounting near actuator, minimize vibration stress |

| Calibration / Trim | ±2.5 % or ±5 % trim via potentiometer (1 kΩ / 2 kΩ) |

| Warranty / Repair Support | Covered under Woodward EPG warranty programs; repair (exchange) options listed in manual 82329 |

Related Models & Alternatives

Here are some peer or alternate modules in the EPG / governor family:

- 8290-192 — the 12 V version of the EPG droop speed controller (analogous to 8290-191 but for 12 V systems)

- 8290-184 — another EPG variant (24 V version) listed in surplus inventories

- 8290-186 — a 12 V EPG controller in similar families

- 8290-190 — EPG 12 V model (without start-fuel capability) in the same product line

- Other Woodward EPG models (e.g. 512, 524, 1712, 1724) — more integrated versions with actuator built-in or higher torque variants

If you plan a system retrofit, you might also consider migrating to more modern electronic governors or microprocessor-based engine control modules capable of droop, isochronous, and load sharing within a unified controller architecture.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626