Description

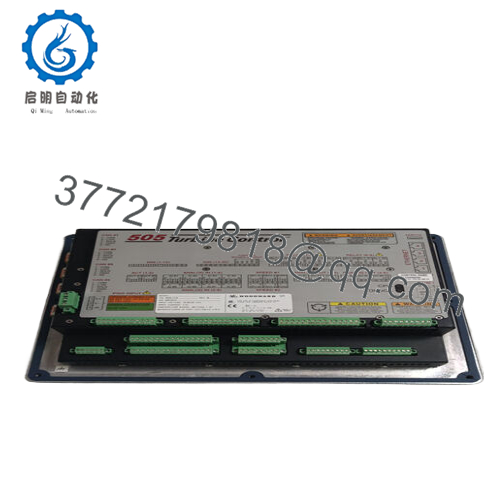

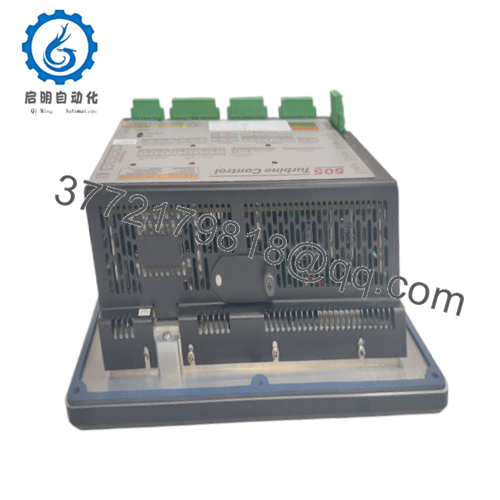

Product Model: 8200-1312

Product Brand: Woodward

Product Series: 505 / 505XT Digital Governor Series

Product Features:

- Integrated graphical HMI and local trending for easier operator oversight

- Adaptive PID algorithms (OptiTune) for optimal performance under load changes

- Communications: Ethernet, RS-485, CANOpen, DCS link

- Certified for marine, hazardous-zone, and industrial turbine environments

Applications & Industry Context

In modern power plants, marine propulsion systems, and industrial steam or gas turbine installations, control stability, reliability, and precision are nonnegotiable. That’s where digital governors step in—and the 8200-1312 finds its sweet spot. Across steam, extraction, and admission turbines, this module ensures operators can respond to load changes, disturbances, or abnormal conditions with minimal overshoot or instability.

You’ll often see the 8200-1312 deployed in combined heat-and-power (CHP) plants, central utility boilers, or marine turbine systems where seamless integration with DCS systems is crucial. For example, in a coastal power plant, the governor must manage steam extraction for feedwater heating while simultaneously controlling turbine speed under transient load swings. Field engineers often remark that older analog governors struggle during rapid ramp events—but controllers like the 8200-1312 sidestep that by virtue of its faster processing speeds and built-in adaptive logic.

In oil & gas, where turbines may drive compressors or generators, the necessity for redundancy, fault diagnostics, and predictive maintenance is real. The 8200-1312 supports vibration monitoring and real-time trending, letting operators foresee mechanical stress or balance issues before they escalate. In hydro or gas settings, it also handles sudden load shedding, synchronization to grid, and safe overspeed protection. Across these industries, the 8200-1312 is trusted to be the automation “brain” for turbine control and protection.

Technical Features & Benefits

When evaluating digital governors, engineers often look for speed regulation, adaptability, communication flexibility, and ruggedness. The 8200-1312 doesn’t disappoint.

One of its standouts is the OptiTune adaptive PID architecture. Rather than relying on fixed PID constants, the unit can adjust gains in real time, helping the turbine remain stable during disturbances or rapid load changes without manual retuning. Combined with acceleration limiting and overshoot suppression, this allows for smooth startup, shutdown, and load transitions.

The integrated graphical HMI deserves attention. Many legacy units require an external panel or laptop for configuration; by contrast, the 8200-1312 offers an on-unit screen that presents real-time trending, alarm history (with timestamps), and a visual “steam map” illustrating extraction/admission control. This reduces diagnostic time in the field.

Communications flexibility is also baked in: Ethernet networking (for DCS link or remote diagnostics), RS-485 or Modbus for legacy systems, CANOpen for actuator networks, and optional distributed I/O via LinkNet-HT modules. That permits extension of I/O capacity without switching to a different controller architecture.

On the protection side, the module supports vibration monitoring (with optional sensor kits), overspeed detection, zero-speed detection, reverse-rotation sensing, and ten external diagnostic/trip inputs. In hazardous environments (marine, zone-2), it’s rated to support ATEX and IEC compliance (in relevant versions).

Design-wise, the controller is built in a rugged enclosure, with unpluggable terminal blocks and modular wiring. That simplifies field replacement or troubleshooting. It also supports a drop-in upgrade for older Woodward 505 units using retrofit wiring kits—helpful when retrofitting older turbine trains.

Engineers in the field often mention that installing a new 8200-1312 is far quicker than older analog units—no need for external consoles or rewriting control logic from scratch if the logic remains compatible.

Installation & Maintenance Insights

Installing a 8200-1312 in a control cabinet requires attention to layout, wiring, grounding, and cooling. First, ensure ambient temperature remains within spec (–40 °C to +85 °C typical) and avoid mounting directly above power electronics that might generate heat. Route speed sensor wiring separately from power wiring to reduce electromagnetic interference. Use shielded twisted-pair cable for proximity or eddy-current probe inputs. In marine or hazardous environments, follow zone isolation practices and grounding schemes.

Use unpluggable terminal blocks so that the module can be swapped without disturbing wiring. When replacing, always back up existing parameter sets using tooling before removal—even if keeping settings the same. During commissioning, run the internal turbine simulator (if enabled) to test startup and ramp logic before connecting to the real turbine.

Routine maintenance should include periodic checks of I/O status, error logs, vibration trend data, and firmware version. Field experience suggests revisiting the adaptive gains after mechanical changes (e.g. after turbine overhaul or balancing). Keep spare terminal modules, and periodically clean fans or ventilation paths in the control enclosure to prevent thermal derating. Finally, always apply software password protection and secure remote access configurations to maintain cyber resilience.

Product Role & System Fit

At its core, 8200-1312 is a digital governor module designed to control turbine speed, load, and extraction/admission flow. As part of the Woodward 505 series (or 505XT variant in some applications) it replaces older analog regulators or first-generation digital units. In a system architecture, it sits between the speed sensor inputs, turbine valves or servos, and supervisory automation systems (DCS or PLC).

In a typical configuration, the 8200-1312 receives two independent speed signals (from magnetic pickups, eddy-current sensors, or proximity probes). It processes these signals, computes control output commands (e.g. 4-20 mA or CANOpen actuator commands), and issues signals to turbine valves or servo actuators. It also exchanges data with higher-level control networks, enabling monitoring, coordinate control, setpoint changes, and diagnostics.

Because of its modular communication stack, it fits seamlessly into modern automation environments. Whether the rest of your plant is controlled by ABB, Siemens, Emerson, or Honeywell systems, the 8200-1312 can integrate via Ethernet, Modbus, or other industry-standard links.

Beyond primary control, it can supervise auxiliary functions: load share, extraction control, limit locks, and protective interlocks. In multi-turbine installations, multiple 8200-1312 units can coordinate via supervisory logic or external controllers for synchronized operation.

- 8200-1312

Technical Specifications Table

| Parameter | Value |

|---|---|

| Input Power Supply | 18–36 VDC (isolated) |

| Operating Temperature Range | –40 °C to +85 °C |

| Dimensions | 263 × 58 × 28 mm (approx) |

| Weight | ~4.3 kg |

| Speed Inputs | Dual channels; magnetic, proximity, or eddy-current |

| Analog Inputs | Up to 8 configurable 4–20 mA channels (loop powered) |

| Discrete Inputs | Up to 10 external contacts (for trips, commands) |

| Analog Outputs | 2 channels (4–20 mA or 0–10 V) |

| Relay Outputs | Up to 8 Form-C relays |

| Communication Interfaces | Ethernet, RS-485, CANOpen |

| Protection & Monitoring | Overspeed, reverse rotation, vibration (optional) |

| Enclosure Rating | IP54 (typical), zone-2 compatible in some models |

Related Models

Here are a few sibling or variant units, along with how they differ:

- 8200-1302 (Woodward 505D LVDC Ordinary Location) — Standard version for non-hazardous environments

- 8200-1310 (405-XT LVDC Ordinary Location) — XT variant without zone-2 compliance

- 8200-1311 (505-XT HVAC/DC Ordinary Location) — AC/DC powered version

- 8200-1330 (505-DR LVDC Ordinary Location) — DR (dual-redundant) model

- 8200-1331 (505-DR HVAC/DC Ordinary Location) — HVAC/DC dual-redundant version

- 8200-1400 (505HT LVDC for Hydro Turbines) — Specialized for hydro applications

- 8200-1401 / 1402 / 1403 — Variants for Pelton / Kaplan / Francis hydro types

Each of these shares the core architecture but differs in power input, redundancy, or specific turbine domain logic (steam vs hydro, redundancy, etc.).

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626