Description

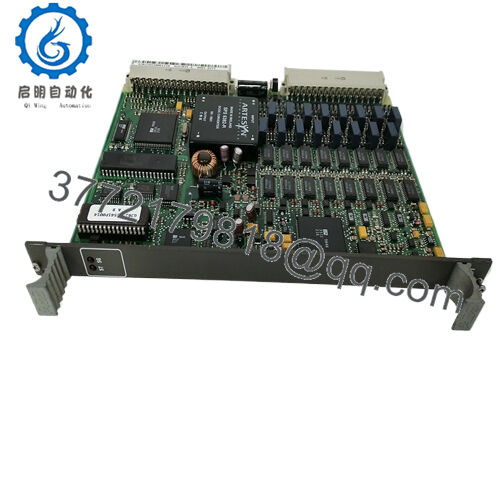

Product Model: 81EU01E-E

Product Brand: ABB

Product Series: Industrial Automation / Turbine & Process Control

Product Features:

- High-performance control module for turbine and process automation

- Designed for ABB rack-based control architectures

- Durable construction for long-term industrial use

- Supported globally with ABB spares and service

- 81EU01E-E

- 81EU01E-E

Oh man, the ABB 81EU01E-E—that takes me back to a gritty upgrade gig in a Norwegian offshore platform back in ’05, where the wind was howling and the salt air was eating everything not bolted down tight. I’d been wrestling with some crusty old transmitters feeding into a PROCONTROL P setup, and the foreman slides this 81EU01E-E across the workbench like it’s the missing puzzle piece. Slotted it into the station bus, configured the channels for a mix of thermocouples and binary contacts, and just like that, the whole analog loop stabilized—no more drift from the cold junction glitches. That was my intro to this little gem from ABB’s legacy lineup, and it’s stuck with me as one of those underrated workhorses for harsh environments.

Picture this: We’re knee-deep in a pulp mill retrofit last year, steam everywhere, and one of the level transmitters starts ghosting us—intermittent faults that had the DCS screaming false alarms on the digester controls. I pop open the rack, eyeball the 81EU01E-E, and run a quick plausibility check on those 16 channels. Turns out, a sneaky wire break on a NAMUR initiator was tripping the monitor, but the module’s built-in diagnostics lit up the disturbance bit in seconds. Swapped the termination, tweaked the bounce suppression to 5 cycles, and we were back online before lunch. Moments like that remind you why ABB engineered these for the long haul; they don’t just collect data, they babysit it.

Here’s the straight dope on the 81EU01E-E‘s guts, pulled from the trenches:

- Channels: 16 universal inputs (binary, analog current, thermocouples S/K/J/L/N, Pt100 RTDs)

- Power Supply: +24 V DC (short-circuit protected per channel)

- Current Consumption: 140 mA base + 2-17 mA per active channel (depending on type)

- Operating Temp: 0°C to 70°C (accuracy holds tight, <50 ppm/K drift)

- A/D Resolution: 12-bit (10-bit for low-range currents)

- Response Time: Binary ~5 ms, analog 80 ms, temperature 320 ms

- Dimensions: 198 mm depth, 261 mm height, 20 mm width (0.5 kg featherweight)

What sets this 81EU01E-E apart in the field? That flexibility—mix binary contacts with 4-20 mA loops or even thermocouples on the same board without breaking a sweat. The monitoring is gold: wire breaks, shorts to ground, all flagged with LEDs and bus telegrams, so you’re not chasing shadows during a shutdown. And those function blocks for corrections? I’ve used the NIV for level comp in tanks—saves you from external hacks and keeps the values crisp.

It shines brightest in legacy DCS spots like power plants or chemical batches, where you’re retrofitting PROCONTROL P without gutting the whole system. Oil & gas platforms love it too, handling the vibe and humidity while pulling temps from remote sensors without noise creep.

But heads up, it’s not all roses. The config lists can be a pain if you’re not versed in ABB’s old EEPROM tricks—load ’em wrong, and you’re rebooting for hours. Plus, in super-high EMI zones, shield those runs religiously; I’ve seen false triggers fry a channel otherwise. If you’re on newer 800xA, think twice—might need adapters for full integration. Still, for reliable I/O on a budget, this 81EU01E-E earns its keep every shift.

Technical Features & Benefits

The 81EU01E-E ABB controller module is designed with the needs of industrial operators in mind. It is not a generic component but a purpose-built part of ABB’s process automation architecture.

Key features include:

- Strong control processing – Executes complex automation logic with precision, handling both routine tasks and high-priority safety interlocks.

- Rugged industrial design – Resistant to vibration, electrical noise, and temperature fluctuations typical of plant floors and control rooms.

- Seamless compatibility – Designed to integrate directly with ABB’s turbine and process automation systems.

- Built-in diagnostics – Monitors internal health and reports anomalies early, reducing unplanned downtime.

- Lifecycle longevity – Supported by ABB’s global service and spare parts network, ensuring availability long after initial installation.

Benefits to end users:

- Higher system reliability and reduced risk of unplanned shutdowns

- Lower maintenance and lifecycle costs due to durability

- Quick replacement and integration thanks to modular rack design

- Confidence in long-term support from ABB’s worldwide presence

Product Role & System Fit

In the automation ecosystem, the ABB 81EU01E-E functions as a control module, processing inputs from sensors, executing programmed logic, and issuing commands to actuators and other modules.

It fits into ABB’s rack-based control systems, where it operates alongside I/O modules, communication processors, and redundant power supplies. This ensures full compatibility and reduces commissioning complexity.

Because ABB designs its modules with redundancy in mind, multiple 81EU01E-E units can be configured together. This architecture provides fault tolerance, allowing operations to continue seamlessly even if one module fails. In industries where downtime costs can reach tens of thousands of dollars per hour, this level of reliability is indispensable.

Installation & Maintenance Insights

Field engineers find the 81EU01E-E easy to install and service. Its modular design allows quick mounting into ABB racks, and once in place, it integrates immediately with the existing automation framework.

Installation best practices include:

- Confirming rack slot assignment and compatibility

- Verifying clean connectors and grounding integrity

- Checking firmware or system software versions for alignment

For maintenance, technicians should monitor environmental factors. While the 81EU01E-E is rugged, excessive dust, poor airflow, or heat buildup in control cabinets can shorten component life. Preventive cleaning and system diagnostics help extend service intervals.

Replacement is straightforward. Operators can swap out the module in less than an hour, minimizing downtime. Because ABB provides consistent design standards across its automation components, no reprogramming is typically required when replacing with an equivalent unit.

Technical Specifications Table

| Specification | Detail |

|---|---|

| Product Model | 81EU01E-E |

| Brand | ABB |

| Module Type | Controller Module |

| Primary Function | Executes turbine & process control logic |

| Compatibility | ABB turbine & process automation systems |

| Processing Power | High-performance industrial CPU |

| Diagnostics | Built-in fault detection and reporting |

| Environmental Design | Vibration and temperature resistant |

| Installation | Rack-based modular slot mounting |

| Serviceability | Field-replaceable, hot-swappable |

| Lifecycle | Long-term supported by ABB global services |

| Typical Applications | Turbines, power, chemical, paper, water utilities |

Related Models

- 81EU01E-D – Previous variant with slightly different rack compatibility

- 81EU02E – Enhanced model with expanded processing power

- DSBC172 – Communication processor module working with ABB controllers

- DSAI130 – Analog input module for the same rack system

- DSMB176 – Logic module complementing the 81EU01E-E

- 87TS01L – Another ABB turbine control module, closely related in function

- DSBC176 – Processor variant offering redundancy features

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626