Description

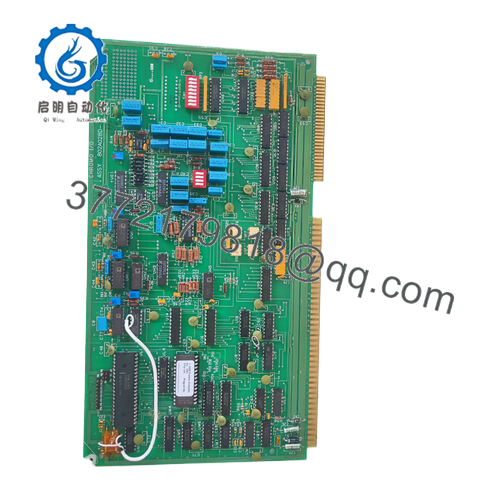

802A028D-3 Product Introduction:

Model: 802A028D-3

Brand: ABB

Type: Signal conditioning and interface module

Input voltage: 24 VDC (± 10%)

Working temperature range: -40 ° C to 70 ° C

Installation method: DIN rail

Size: 100 x 50 x 30 millimeters

Weight: 0.25 kilograms

Interface/Bus: RS-485, Ethernet

Compliance: ABB, RoHS

Supported protocols: Modbus RTU, Profibus DP, CANopen

Typical power consumption: 4 watts

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

Choosing 802A028D-3 can bring many practical benefits to industrial operations. This module is designed specifically for harsh industrial environments, ensuring long-term performance and reliability. Its sturdy structure and advanced signal conditioning technology make it highly resistant to electromagnetic interference, vibration, and temperature fluctuations, which are common in industrial environments.

The widespread support for multiple communication protocols simplifies system integration and reduces the complexity and cost of implementing new automation solutions. By improving signal integrity, 802A028D-3 enhances the accuracy of data transmission, thereby achieving more precise control over industrial processes. This in turn improves product quality, reduces waste, and increases productivity.

The built-in diagnostic function significantly contributes to maintenance efficiency. Engineers can quickly identify and troubleshoot faults, minimizing unplanned downtime and related costs. The modular design of this module facilitates installation and replacement, further reducing maintenance time and effort. Overall, 802A028D-3 is a valuable investment that enables various industries to optimize their automation systems, improve operational efficiency, and gain a competitive advantage in the market.

Application areas:

802A028D-3 has a wide range of applications in various industries. In the automotive manufacturing industry, it is used to manage communication between sensors on production lines and central control systems. It ensures accurate transmission of data related to vehicle assembly, such as bolt torque levels and component positions, thereby achieving precise and consistent production.

In the chemical processing industry, safety and process control are crucial, and 802A028D-3 plays a key role in monitoring and controlling chemical reactions. It accurately transmits data from sensors measuring temperature, pressure, and chemical concentration to the control system for timely adjustment, ensuring safe and efficient operation.

In the oil and gas industry, this module is used to manage communication between remote sensors on pipelines and drilling platforms and onshore control centers. Even in harsh and remote environments, it ensures reliable data transmission, enabling operators to monitor and control critical processes, detect leaks, and optimize production.

Related products:

802A028D-4: Upgraded version with enhanced signal processing capabilities, suitable for scenarios that require higher precision and faster data processing.

802A028D-2: An economical alternative with basic signal conditioning functions, suitable for less complex industrial automation settings.

802A029D-3: Variant product with additional communication interfaces, providing more flexibility for integration with a wider range of devices.

802A028E-3: With improved diagnostic capabilities, it provides more detailed insights for troubleshooting complex signal related issues.

802A027D-3: Compact version with smaller external dimensions, suitable for space limited installations without sacrificing core functionality.

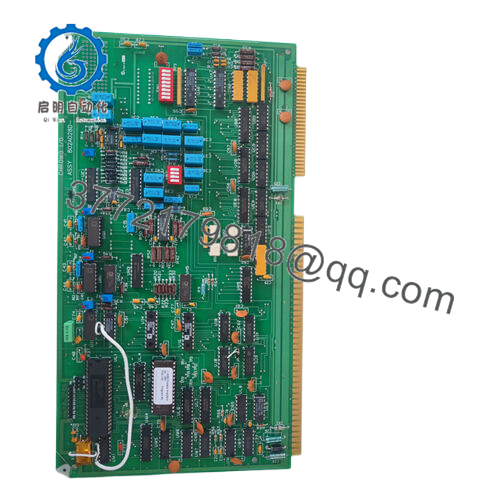

Installation and maintenance:

Preparation before installation: Before installing 802A028D-3, it is necessary to verify the compatibility of the communication protocol and input voltage with the existing automation system. Ensure that the DIN rail installation position has sufficient space and is properly grounded to prevent electrical interference. Check the integrity of the RS-485 and Ethernet cables used for connection, as faulty cables may cause communication issues.

Maintenance suggestion: For continuous maintenance, the diagnostic indicator lights of the module should be checked regularly. LED status lights can provide valuable information about the operating status of modules, such as signal activity, power supply, and error warnings. Regularly clean the module to remove dust and debris, especially in dusty industrial environments, as this may affect its performance. It is recommended to regularly update the firmware of the module to benefit from the latest performance improvements, security patches, and compatibility enhancements. Conduct annual performance testing to ensure that the module operates within the specified parameter range and promptly resolves any issues to avoid interruptions to the automation system.

Other models of ABB series:

RED670 1MRK002246-BC

RED670 1MRK002810-AC

RED670 LCD screen

REF 543

REF541

REF541DB115BAAA

REF541KM115AAAA

REF541REF541KM118AAAA

REF615 HBFFAEAGNEA1ANA11G

REF615 HBFDACAFNEA1ANN11G

REF615 HBFCABABC1ANN11G

REF615 HBFDACADABC1ANN2XG

REF615A_1G

REF615C_D

REF615E_1G HBFCACABAAC1ANN11G

REF615E_1G HBFEAEAGNEA1ANA11G

REF615E_D

REF615E_E HBFFAEAGABC1BNA2XE

REF615E_G HBFHAEAGANB1BAN1XG

REF615E_G HBFHAEAGANB1BAN1XG

REF615 English version

REF620

REF620E-1GNBFNAANNNDA1BNNN11G

REG216EA62

REG216Vc62a

REG670 1MRK002826-AC

REJ601 BD446NN1XG

REJ603B2NN1NB44NNJ

REL316

REL511 1MRK003492-AL

REM 545

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626