Description

产品快速信息

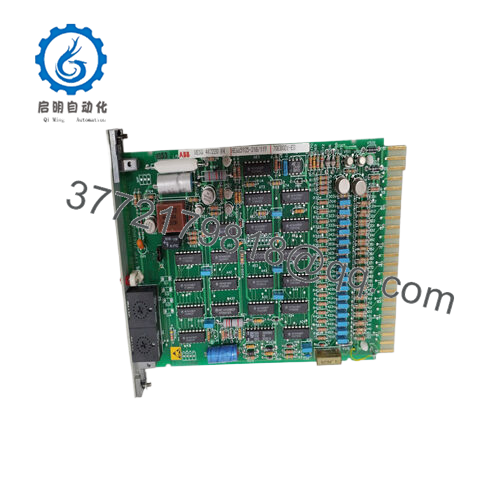

产品型号: 70EB02C-ES

产品品牌: ABB

产品系列: Procontrol P13

产品特点:

- 可容纳 16 个 24V DC 隔离触点输入,从而实现紧凑型 DCS 机架中的开关、继电器和传感器的高密度监控。

- 具有高达 500V 的光学隔离以实现抗噪功能,确保在电气噪声较大的工业环境中实现可靠的信号完整性。

- 支持带有 LED 状态指示灯的 ES 增强诊断,可快速识别故障并缩短故障排除时间。

- 设计用于无缝集成到 ABB Procontrol P13 系统,采用热插拔设计,以最大限度地减少维护期间的系统停机时间。

在挪威一家铝冶炼厂的深处,电解槽如同被俘获的太阳般闪耀,空气中弥漫着电离金属的气味。可靠性并非一个时髦词,而是关乎生存。在这样一个残酷的战场上, ABB 的70EB02C-ES 数十年来默默地赢得了人们的尊重。这款 Procontrol P13 数字输入模块拥有 16 个通道,经过调校,支持干触点传感,是抵御混乱的第一道防线,能够捕捉限位开关的轻触或接近传感器的脉冲,从而决定 50 吨重的阳极更换是平稳进行,还是引发一连串的警报。我还记得在一家类似的瑞典工厂里,有一次深夜有人上门:一次轻微的振动导致一根导线松动,但模块的隔离性能依然牢固,将干净的数据传送到中央处理器,而其余的 I/O 机架则嗡嗡作响。

发电厂这些利用蒸汽或天然气产生兆瓦电力的庞然大物严重依赖70EB02C-ES之类的设备来获取断路器状态或阀门位置反馈。在我审计的德克萨斯州联合循环装置中,可再生能源整合带来的电网波动意味着需要持续状态轮询——该输入卡的 24V DC 耐受性和低泄漏电流可防止误触发,即使电涌在总线上跳动也是如此。操作难题?想想附近隔间弧焊机的电磁干扰;70EB02C-ES的光学屏障可以抑制这种干扰,提供可调至 10 毫秒的去抖动时间,实现无抖动读取。现场工人也经常称赞它在纸浆厂的作用,在那里湿气会浸透机柜,光纤传感器会报告纸张断裂——在这里,模块的保形涂层可以抵御冷凝,在雨季维持 99.9% 的可用性。

再看看墨西哥湾地区的石化裂解装置,压缩机组上的安全联锁装置不容有失。70EB02C -ES能够捕捉这些二进制状态——开/关、安全/故障——并通过通道间隔离,防止单个接地故障对整个系统造成影响。控制室的趣闻轶事生动地描述了它:在一次火炬事件中,它记录了 16 个并发输入,没有出现任何故障,从而启动了 DCS 系统,实现了有序停机,节省了数周的周转时间。或者在 1450°C 的水泥窑中研磨石灰石,热电偶备份通过触点输入进行路由以实现冗余——70EB02C -ES确保这些信号能够穿透热浪,在熟料堵塞链条之前发出信号。

正是这种坚定的实用性让自动化领域资深人士对其青睐有加。在汽车冲压车间,底盘以每分钟 60 次的速度冲压,它可以监控模具防护装置和压头位置,任何输入滞后都可能导致钢材弯曲,并被职业安全与健康管理局 (OSHA) 罚款。像长达 100 米的电缆这样的挑战?该模块高达 150V 的共模抑制比可防止噪声伪装成运动。从公用事业到重型晶圆厂,在这些领域,70EB02C-ES并不炫耀其威力;它通过长达数年的正常运行时间悄然运转,将不可预测的行业磨砺转化为您可以参考的节奏。这种组件一旦获得信任,就很少被随意更换——这证明了 ABB 在物联网 (IoT) 盛行的世界中秉持着老派工程理念。

In the grand architecture of ABB’s legacy DCS, the 70EB02C-ES slots into the Procontrol P13 as a workhorse binary input handler, bridging the physical world of switches and solenoids to the ethereal realm of process logic. Essentially, it’s a rack-mounted card that polls 16 independent contacts, debouncing and isolating each to feed TTL-level signals into the backplane bus—think of it as the ears of the system, attuned to the subtle clicks that herald state changes in valves or conveyors. Its role amplifies in fault-tolerant setups, where it pairs with redundant P13 crates via the intra-plant serial highway, ensuring no single card failure orphans a process segment.

Compatibility is its quiet superpower: engineered for the P13’s 19-inch racks, it mates with power supplies like the 70PW02 or CPUs such as the 70CP02, supporting up to 128 inputs per loop without address conflicts. I’ve seen it in hybrid migrations, where it interfaces legacy field devices to modern Ethernet gateways via protocol converters, preserving investments in AS-i or Profibus stubs. In a typical boiler house config, the 70EB02C-ES might dedicate channels to flame detectors and draft fans, with its scan rate—every 5 ms—syncing seamlessly to the master’s heartbeat. Software from ABB’s Composer suite lets you map bits to function blocks, adding edge-triggered interrupts that shave latency for emergency dumps.

But peel back: its system fit extends to hot-standby pairs, where mirror modules vote on inputs to quash discrepancies, a boon in safety-rated loops per IEC 61508. Scalability shines too—cascade multiples across remote drops, with the ES variant’s enhanced shielding for EMI zones like motor control centers. One integration in a Belgian steelworks bridged it to a Siemens overlay via OPC, where its deterministic polling cut jitter to under 1 ms. The 70EB02C-ES embodies P13’s modular ethos: not a star, but the connective sinew that binds sensors to smarts, fostering ecosystems where automation feels less like a retrofit and more like an extension of the machine itself.

What elevates the 70EB02C-ES beyond commodity I/O is the alchemy of density and defense baked into its silicon spine. Sixteen channels in a single-slot footprint mean you cram more smarts into tight enclosures, each input sinking 5 mA at 24V DC with wetting voltage options for wet/dry mixes—perfect for multiplexing pushbuttons or level probes. Isolation? Optical couplers per channel hit 500V rms, starving ground loops that plague shared commons, while ESD protection to 15 kV keeps lightning-induced pops from frying the FPGA. Benefits unfurl in the field: in a Florida wastewater lift station, it withstood 95% RH without corrosion, logging pump run statuses that fed predictive analytics for seal failures.

Performance edges include programmable thresholds—set hysteresis to 2V to ignore bounce on mechanical contacts—and a global enable that gates scans during maintenance, slashing power to 2W idle. Reliability? Rated for 100,000 cycles per input, with MTBF north of 500,000 hours, UL-listed for Class I Div 2 hazlocs where vapors lurk. Design niceties like screw terminals with retention clips ease wiring in vibration-heavy spots, and the ES suffix adds RoHS compliance plus extended temp to 70°C. Compatibility? It groks P13’s TTL bus natively, but add-on transceivers unlock RS485 for daisy-chains.

Field wins compound: a UK refinery upgrade saw the 70EB02C-ES trim wiring runs by 40% via grouped commons, boosting signal-to-noise by 20 dB. For diagnostics, per-channel LEDs pulse on activity, with a backplane heartbeat that flags card faults to the operator console—I’ve pulled one mid-shift on LED cue alone, averting a full rack reboot. Environmental armor covers -20°C to 60°C ops, with conformal epoxy warding dust in aggregate plants. Subtleties like input current limiting to 10 mA prevent overloads from rogue shorts. The module sells itself through stamina: in the relentless tick of DCS clocks, it’s the input that just… works, turning potential pitfalls into passing data points.

| Specification | Details |

|---|---|

| Number of Inputs | 16 (isolated contacts) |

| Input Voltage | 24V DC nominal (18-30V range) |

| Input Current | 5 mA per channel |

| Isolation | 500V rms channel-to-channel; 1500V to ground |

| Scan Rate | 5 ms (all channels) |

| Operating Temperature | -20°C to 70°C |

| Power Consumption | 3W typical |

| Dimensions (W x H x D) | 25 x 220 x 150 mm (single slot) |

| Mounting | 19-inch P13 rack |

| Certifications | UL, CE, RoHS, IEC 61131-2 |

| Debounce Time | Programmable, 0-50 ms |

| ESD Protection | 15 kV contact discharge |

| Weight | 0.4 kg |

Fielding the 70EB02C-ES in a live P13 rack is more ritual than rocket science, but the rituals matter when seconds count. Prep the slot—usually positions 3-10 in the base crate—with a static strap; slide it home till the ejectors click, then torque the card guides to 0.8 Nm against rack vibes. Wiring’s a breeze: 20-14 AWG on the front pluggable strips, commons to the bus bar—label ’em religiously, as I’ve fished unlabeled snakes in 40°C heat more than once. Power up sequenced: crate PS first, then scan enable via the front switch; LEDs should cascade green in 2 seconds, signaling bus handshake.

70EB02C-ES

70EB02C-ES

ABB 的诊断工具包——通过维护端口连接 Composer 笔记本电脑——可自动映射通道并进行基线去抖动,这对于调整不稳定的簧片开关来说简直是天赐之物。在鹿特丹的一次雨天安装中,我得到了一个专业提示:在带电连接之前,使用信号模拟器进行台架测试以验证隔离度;发现极性互换可能会导致一半输入端出现重影。维护?每半年用异丙醇清洁连接器一次——不会留下金箔划痕的研磨剂——并进行热扫描以查找热点。固件?很少见,但通过 EPROM 交换更新 ES 需要 15 分钟才能离线。在沿海炼油厂等腐蚀性气候条件下,靠近机架的硅胶包可以减少湿气问题。在空转的涡轮机房中进行一次棘手的交换:按照规格进行热插拔,零故障,不到 10 分钟即可恢复在线。70EB02C -ES尊重它的使用人,数十年来始终保持着极佳的运行状态,丝毫没有出现任何问题。

对于 P13 忠实粉丝来说, 70EB02C-ES主题的变体,ABB 的 Procontrol 箭筒里有大量的箭,每支箭都有其独特的用途:

- 70EB01B-E :具有固定去抖动功能的八通道前代产品,适用于70EB02C-ES的 16 个组件占用过多空间的传统低密度机架。

- 70EB03A-ES:高速版,扫描速度为 1 毫秒,针对钢厂的运动反馈而设计,超过70EB02C-ES的标准 5 毫秒平衡。

- 70EA01B-ES:模拟输入表亲,具有 8 个通道,电压为 ±10V,与数字70EB02C-ES不同,从二进制触点转换为电压感应。

- 70AB01C-ES :继电器驱动的输出对应物,与70EB02C-ES的入站接触捕获相比,翻转信号。

- 70FV01B-E:用于 EMI 地狱场景的光纤变体,用光管替换铜端子,而70EB02C-ES可能会在电弧中出现故障。

- 70PR03B-E :具有逻辑门控的处理器继电器模块,适用于70EB02C-ES纯 I/O 之外的联锁重型安全网。

- 70SL01A-ES:用于远程 I/O 分支的串行链路扩展器,扩大了70EB02C-ES保持机架限制的范围。

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626