Description

Product Quick Info

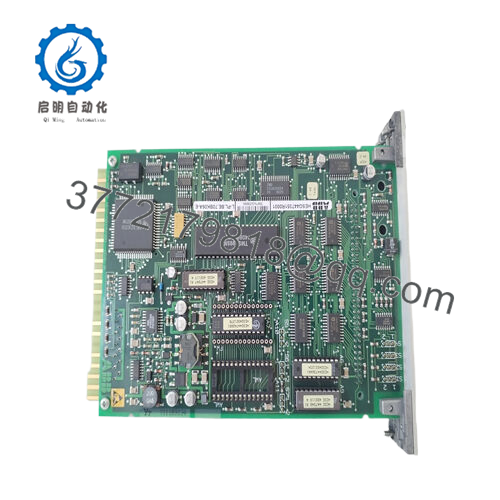

Product Model: 70EA05A-E

Product Brand: ABB

Product Series: Procontrol P13

Product Features:

- Supports 8 isolated analog inputs for voltage, current, RTD, and thermocouple signals, offering flexibility in process monitoring.

- Provides 500V channel-to-channel isolation for superior noise rejection in harsh electrical environments.

- Features 16-bit A/D conversion for high-resolution data acquisition, ensuring accurate control in dynamic applications.

- Integrates seamlessly with P13 DCS racks, with built-in diagnostics to facilitate quick fault detection and maintenance.

Sweat hangs heavy in the control room of a sprawling Louisiana petrochemical complex, where distillation towers rise like steel sentinels under the relentless Gulf sun, processing crude into the lifeblood of industry. In this cauldron of pressures and flows, where a sensor glitch can trigger a runaway reaction, the 70EA05A-E from ABB stands as the unflappable translator, pulling analog whispers from thermocouples and transmitters into the digital dialogue of the Procontrol P13 DCS. I’ve lingered in similar setups—a Saudi refinery where it monitored catalyst bed temps across 20 zones, its steady conversions holding sway against the 50 Hz hum of transformers, preventing a hot spot that could’ve idled the unit for weeks.

Thermal power stations, those iron-hearted giants belching steam from coal or gas, rely on modules like the 70EA05A-E to gauge everything from flue gas oxygen to turbine inlet pressures. In a Polish lignite-fired plant I consulted on, grid-mandated emissions cuts meant tighter loop tuning; this input card’s multi-range scaling—from 0-10V to ±50 mV—adapted without recalibration, feeding clean data to PID controllers that shaved NOx by 15%. The headaches? Electromagnetic barrages from switchgear arcs that scramble lesser boards. Here, the 70EA05A-E‘s optical isolation fortifies against them, with common-mode rejection north of 120 dB ensuring signals arrive pristine, even over kilometer-long runs.

Picture pulp and paper mills in British Columbia, where bark shredders roar and digesters stew wood chips at 160°C under caustic brews. The 70EA05A-E ingests pH and consistency feedbacks from those corrosive realms, its RTD channels linearizing PT100 curves to 0.05% accuracy, averting digester explosions from foam overflows. Field lore from a veteran operator: during a steam leak scare, it flagged a drifting 4-20 mA loop from a faulty transmitter, isolating the channel via software latch before the cascade hit the boiler feed pumps. Or shift to water treatment in arid Israeli facilities, desalinating brine with reverse osmosis membranes—here, the module’s millivolt inputs track conductivity spikes, integrating with SCADA for automated dosing that keeps output potable without waste.

Engineers gravitate to this automation component for its no-nonsense fortitude. In cement works grinding clinker at 300 tons per hour, it handles vibration-induced noise on load cells, with programmable filtering that smooths readings without lag. Challenges like multiplexer crosstalk in dense racks? The 70EA05A-E‘s per-channel amps quash it, supporting burnout detection that spots open wires before they blind a loop. Across these sectors—from refining to renewables—the module demystifies the analog-to-digital divide, turning raw sensor babble into actionable insights. It’s the steadfast scribe in the ledger of industrial resilience, where every volt captured counts toward margins that matter.

At the core of ABB’s venerable Procontrol P13 ecosystem, the 70EA05A-E functions as a sentinel for analog ingress, channeling continuous signals from the plant floor into the discrete world of control logic. Fundamentally, it’s an 8-channel multiplexer with sigma-delta A/D converters, sampling at up to 100 Hz per channel to digitize voltages, currents, or resistance bridges—envision it as the system’s palate, discerning subtle shifts in process variables like level or flow that dictate actuator responses. In P13 architectures, it perches in I/O crates alongside digital siblings, backplane-linked to processors like the 70PR03 for sequenced scans that sync with the 10 ms task cycle.

Integration is intuitive: drop it into any expansion slot, addressable via DIP switches, and it communes via the local data highway, compatible with redundant pairs for SIL-2 loops under IEC 61511. I’ve fitted it into brownfield expansions, where it bridged legacy 4-wire RTDs to Ethernet overlays through protocol adapters, preserving the P13’s deterministic backbone. Typically, in a boiler drum setup, the 70EA05A-E might claim four channels for steam pressures and four for water levels, with its cold-junction compensation auto-correcting thermocouple offsets for sub-1°C fidelity. ABB’s Function Block Diagram editor maps these inputs to control strategies, enabling cascade or ratio schemes that layer precision atop raw acquisition.

Yet its role deepens in hybrid environs: for instance, in motor control centers, it conditions tachometer outputs alongside current transformers, feeding vector algos that optimize slip. Scalability? Stack up to 64 modules per loop, with global calibration commands cutting setup time. A gas turbine annex I wired used it to unify disparate sensor types—RTDs for bearings, mVs for vibes—into a unified namespace, streamlining HMI views. The 70EA05A-E doesn’t dominate the stage; it sets it, harmonizing the analog chorus into symphonies of synchronized control that keep complex plants in lockstep.

Delving into the 70EA05A-E‘s innards uncovers a mastery of measurement: 16-bit resolution across bipolar or unipolar ranges, with linearity holding ±0.1% to deliver process-grade fidelity that rivals lab gear. Input impedance? 1 MΩ for voltages, 250 Ω for currents, ensuring negligible loading on fragile transmitters. Benefits accrue swiftly—in a Brazilian ethanol distillery, its high CMRR tamed ground potentials from VFD harmonics, stabilizing fermenter controls and lifting yield by 3%. Design standouts include pluggable terminals for field swaps under load, and per-channel scaling via EEPROM that survives power cycles.

Reliability permeates: dielectric withstand to 1 kV, with transient suppressors zapping surges to 600W peaks, UL-recognized for Class I Div 2 where solvents simmer. Field advantages? Built-in excitation for 2-wire RTDs cuts wiring costs by half, while diagnostic registers flag over/under-range or sensor faults, piping them to the operator panel. Compatibility spans the spectrum: thermocouples from J to S types, with linearization tables embedded, or straight mA loops for smart devices. Environmental mettle covers -25°C to 70°C, with vibration tolerance to 5g—battle-tested in offshore platforms where heaves test every solder joint.

70EA05A-E

70EA05A-E

Nuances elevate it: software-selectable filters (50/60 Hz notch or low-pass) tailor noise rejection, and the E-suffix adds enhanced EMC per IEC 61000-6-2. In a Finnish pulp dryer, deploying the 70EA05A-E halved calibration drifts, extending intervals to yearly. For multivariable apps, its burst mode samples all channels in 10 ms, ideal for transient capture in surge tanks. Power thrift at 4W eases rack cooling, and LED ladders per channel spotlight excursions at a glance. The module captivates through calibration— not cacophony, but calibrated clarity that turns sensor static into strategic signal, a quiet revolution in the analog arena.

| Specification | Details |

|---|---|

| Number of Channels | 8 (differential/isolated) |

| Input Types | Voltage (±10V, ±5V, 0-10V), Current (0-20mA, 4-20mA), RTD (PT100), TC (J/K/T etc.), mV (±50mV) |

| Resolution | 16-bit |

| Accuracy | ±0.1% of span |

| Isolation | 500V channel-to-channel; 1500V to backplane |

| Sample Rate | Up to 100 Hz per channel |

| Operating Temperature | -25°C to 70°C |

| Power Consumption | 4W typical |

| Dimensions (W x H x D) | 25 x 220 x 150 mm (single slot) |

| Mounting | 19-inch P13 rack |

| Certifications | CE, UL, IEC 61131-2 |

| Common-Mode Rejection | >120 dB at 50/60 Hz |

| Weight | 0.45 kg |

Seating the 70EA05A-E in your P13 ensemble is less ordeal than orchestration, but the prelude sets the tone. Clear the slot—often mid-rack for thermal balance—with ESD precautions; insert till the levers latch, then secure with captive screws at 1 Nm to defy conveyor shakes. Cabling ritual: shielded pairs to the I/O plugs, drains grounded at the shield bar—I’ve debugged phantom drifts from floating shields in a noisy steel slab mill. Energize in phases: rack power, then module enable; front LEDs should sequence amber to green in 5 seconds, affirming bus sync.

ABB’s Maintenance Terminal shines for onboarding—serial tether to download cal factors, or clone from a master card via the tool’s library. A pearl from a stormy North Sea platform: zero the offsets offline with shorting bars, nailing baselines before brine exposure. Upkeep? Annual span checks with a Fluke calibrator; the self-test mode cycles channels to flag A/D drift. In dusty kilns, nitrogen purges on enclosures fend off conductive films. Firmware tweaks? EPROM burns in 20 minutes, but verify checksums post-burn. One edge-of-seat exchange in a live fractionation tower: hot-swapped with a dummy load, inputs mirrored seamlessly, resuming in under 15. The 70EA05A-E reciprocates respect with rhythms unbroken, a module that matures gracefully under the gaze of vigilant hands.

P13 purists pondering peers to the 70EA05A-E will find ABB’s analog arsenal rich—each variant honing a harmonic:

- 70EA01B-E: Four-channel legacy with fixed ranges, for slimmed-down legacy tie-ins where the 70EA05A-E‘s eight-pack adds density without bulk.

- 70EA02A-E: High-speed sibling at 1 kHz sampling, primed for vibration spectra over the 70EA05A-E‘s process-paced 100 Hz.

- 70EA03A-E: Thermocouple specialist sans RTD support, narrowing to mV focus versus the 70EA05A-E‘s universal embrace.

- 70EA04A-E: Current-only edition with HART passthrough, for smart transmitters where the 70EA05A-E suffices in basic loops.

- 70EI05A-E: Pulse/tach input counterpart, geared for speed pickups unlike the 70EA05A-E‘s steady-state analog.

- 70AA02A-E: Output mirror for analog driving, flipping acquisition to actuation beyond the 70EA05A-E‘s inbound role.

- 70ER01A-E: RTD expander with 4-wire excitation, augmenting resistance reads where the 70EA05A-E handles basics.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626