Description

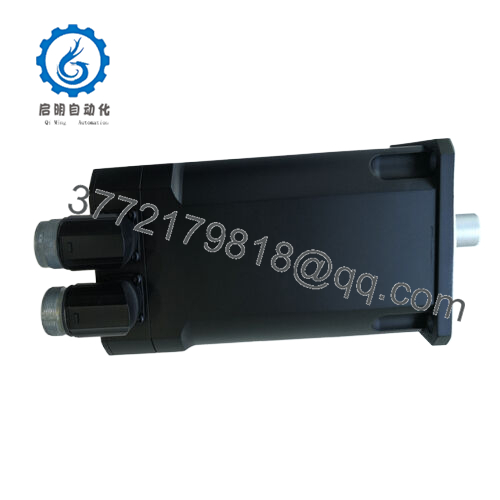

Product Model: 6SM57M-3.000

Product Brand: Kollmorgen

Product Series: 6SM synchronous servo motors

Product Features:

- Nominal 1.40 kW continuous power at 3000 rpm, rated current ~4.3 A

- High torque density and low cogging support smooth motion

- Built-in feedback (resolver or encoder option) for precise control

- Rugged design for industrial operation, matching speed/torque curves in 6SM family

Technical Specifications

| Specification | Description / Value |

|---|---|

| Model | 6SM57M-3.000 |

| Series | 6SM synchronous servo motors |

| Continuous Power | ~1.40 kW |

| Rated Current | ~4.3 A |

| Rated Speed | 3000 rpm |

| Torque (approx) | ~8.0 Nm (some variants) |

| Protection / Ingress | IP64 for some variants |

| Operating Temp Range | 0 °C to +55 °C (typical) |

| Storage Temp | –20 °C to +70 °C |

| Weight / Dimensions | ~2.5 kg, dimensions 140 × 160 × 165 mm (as per one vendor) |

| Feedback / Encoder | Resolver built in (6SM family spec) |

| Motor Type | Brushless synchronous (servo) |

Keep in mind: different variants (brakes, sealing, feedback options) may have slightly different specs. Always consult your motor’s nameplate or full datasheet for precise values.

Applications & Industry Context

The 6SM57M-3.000 is often selected in industrial automation where precise control, high repeatability, and compact dynamics matter. Typical use cases include:

- Robotic axes & joints: where quick acceleration, deceleration, and accurate trajectory following are required

- Indexing or rotary tables: packaging or assembly machines that reposition parts accurately

- Machine tools or CNC auxiliary axes: for secondary axes or ancillary mechanisms

- Pick-and-place, pickers, gantries: where compact, responsive motors are needed

- Motion control subsystems: in larger machines, as modular axes motors

Within the broader 6SM series (6SM27 … 6SM107), this 57-frame M-class motor balances torque and size, making it a go-to for mid-power axes. The torque curves, thermal ratings, and feedback provisions are designed to match digital servo amplifiers in high-dynamics systems.

Often engineers use it with Kollmorgen’s Servostar or S-series drives, or compatible third-party amplifiers, leveraging the resolver or encoder feedback. The integrated feedback allows closed-loop velocity, position, and torque control — critical in high-precision automation.

Technical Features & Benefits

The 6SM57M-3.000 offers a number of features and benefits that tend to stand out in field usage:

1. Smooth, Low-Cogging Torque

Because it’s a synchronous servo motor designed for motion tasks, the design minimizes cogging torque, enabling smoother low-speed moves and better micro-movement behavior. The published 6SM series torque curves illustrate this emphasis.

2. Integrated Feedback (Resolver / Encoder)

As common in the 6SM family, the motor supports internal resolver feedback (or encoder in some variants). This gives precise rotor position for the servo amplifier, enabling tight position/velocity control loops. The family manuals describe how the servo amplifiers evaluate the resolver.

3. Thermal & Mechanical Robustness

The motor is built to withstand industrial environmental stresses. In the 6SM series documentation, manufacturers note features like optimized heat dissipation (ribbed housings) and temperature monitoring sensors.

Additionally, the motor can optionally include radial seals, braking options, and construction modifications (option flags like “-J-”, “-G-”) to support various mechanical environments.

4. Mechanical Flexibility & Modularity

Because the 6SM series is modular across sizes (frame 27 up to 107), designers can carry over mounting, coupling, and feedback practices across power classes. The 57M variant hits a mid-tier in that family — offering a good balance of torque without being oversize.

5. Compatibility & Proven Ecosystem

Because it’s part of Kollmorgen’s well-known lineup, many motion control systems, drive platforms, and integration environments already support 6SM motors. That reduces integration overhead and risk.

When combined, these features yield a motor that is versatile, precise, and durable in real industrial settings.

- 6SM57M-3.000

Installation & Maintenance Insights

To get reliable, long-term performance from a 6SM57M-3.000, follow some best practices drawn from the 6SM series guidelines and field experience:

Mounting & Alignment

- Use rigid, vibration-resistant mounting surfaces, with no mechanical stress on the shaft or bearings

- Align couplings carefully; avoid radial or axial misalignment

- Avoid over-constraining the motor shaft with extra external bearings or rigid coupling setups unless designed correctly (documentation warns against constrained mountings)

Cooling & Heat Management

- Although many variants are designed to dissipate heat naturally, avoid enclosing the motor in a sealed cabinet without ventilation

- For heavy-duty or continuous operation, consider forced ventilation if thermal limits are approached

- Periodically check motor surface temperature — avoid touching the motor when hot (surface may exceed 100 °C in some conditions)

Feedback Wiring & Shielding

- Route resolver or encoder leads away from high power or noisy cables

- Use shielded twisted-pair cabling; terminate shields per motor wiring diagrams

- Check shielding integrity and connector mating to avoid signal interference or loss

Electrical Connections

- Verify phase wiring and sequence before full energization

- For variants with holding brakes (if applicable), follow correct wiring (voltage, suppression elements) and test brake release

- Use proper cable sizing, reduce voltage drop, and include EMC filters or chokes as needed

Commissioning & Tuning

- Use the appropriate servo amplifier or drive software to detect motor parameters: resistance, inductance, feedback settings

- Run test routines at low speed first, verifying smooth response, correct direction, position loop stability

- Gradually ramp to full speed while monitoring current, torque, temperature

Maintenance & Inspection

- Periodically check for bearing noise or vibration — early signs of wear

- Inspect connectors, ensure no corrosion or looseness

- Verify feedback signals and resolve any drift or signal errors

- If motor has optional features (e.g. brake, seals), test them (e.g. brake engagement) in situ

With these practices, the motor can endure thousands of operating hours with stable performance.

Related Models / Variants

Here are some sibling or variant models in the 6SM / 6SM57 family:

- 6SM57M-3.000-G — variant with integrated holding brake

- 6SM57S-3.000 — “S” variant with different torque or feedback combination

- 6SM77K-3.000 — larger frame variant in the 6SM series

- 6SM37M-4000 — different speed / torque class in the series

- Other 6SM series motors (frame 27, 47, 107) — offering different power/torque tradeoffs

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626