Description

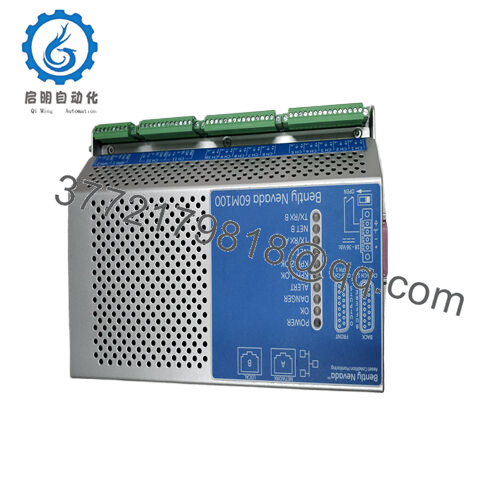

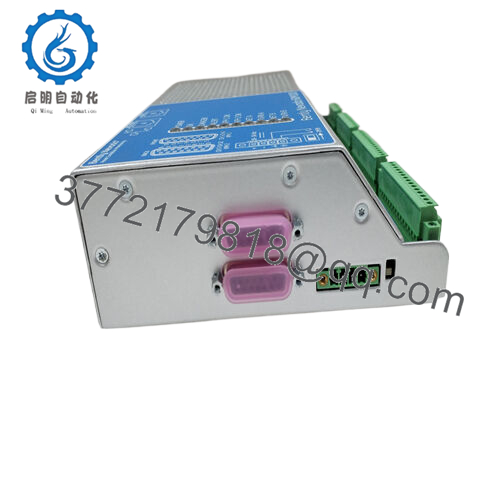

60M100-00 is a high-performance motion controller designed to simplify complex automation workflows. As the core component of the advanced motion control platform of [brand], it serves as a bridge between the human-machine interface (HMI) and physical actuators, converting operator commands into precise mechanical movements. This controller is compatible with servo motors and stepper motors, suitable for modular control architecture, allowing engineers to extend the system from single axis configuration to multi robot unit configuration.

60M100-00

The unique feature of 60M100-00lies in its dual core processing architecture, which separates logic execution from motion planning to ensure deterministic performance. For integrators, this means reducing latency in multitasking environments, such as managing pick and place operations while monitoring safety interlocks. It supports industry standard protocols such as EtherCAT and PROFINET, making it easy to integrate with PLC, SCADA systems, and IIoT platforms, making it a flexible choice for upgrading smart factories. Whether it’s retrofitting legacy systems or designing cutting-edge automated production lines, the 60M100-00 can meet the reliability and flexibility needs of modern manufacturers.

60M100-00

Main features and advantages:

The 60M100-00 performs excellently in terms of functionality and performance, supporting up to 16 interpolation axes with a synchronous update rate as low as 1 millisecond. Its advanced trajectory planning algorithm, including cubic spline and acceleration limited motion, can achieve smooth, vibration free motion at speeds exceeding 500 millimeters per second, which is crucial for high-throughput applications such as electronic component mounting. The controller adopts a sturdy metal casing and can operate continuously in harsh environments (IP30 level). Its thermal design optimization can maintain stable performance in the temperature range of -10 ° C to+55 ° C.

In terms of hardware, its compact external dimensions (120 x 80 x 50 millimeters) and DIN rail installation method can simplify installation in control cabinets with limited space. This module has front accessible I/O ports for easy wiring and is equipped with diagnostic LEDs that can quickly identify communication or power issues. In terms of compatibility, it natively supports [brand]’s motion software suite, enabling drag and drop programming for complex paths, and also provides SDK for third-party PLC programming environments such as CODESYS.

Long term reliability is guaranteed by fault-tolerant design, including redundant power input and ESD/EMI protection. Independent testing has shown that its mean time between failures (MTBF) exceeds 100000 hours, making it a low maintenance option for 24/7 production lines. Engineers appreciate its built-in predictive maintenance features, such as real-time monitoring of motor health indicators (such as temperature, current), which help prevent unplanned shutdowns.

60M100-00

Technical specifications:

Model 60M100-00

Brand BENTLY

Type: Motion Controller/Multi axis Drive Module

Power supply 24 V DC (± 15%)

Working temperature range -10 ° C to+55 ° C

Installation method: DIN rail/panel installation

Dimensions 120mm (width) x 80mm (height) x 50mm (depth)

Weight 0.6 kilograms

Communication protocols EtherCAT, PROFINET, Modbus TCP

Maximum support for 16 axes (synchronous interpolation)

Control mode position, speed, torque

Certified CE, UL, RoHS

Heat dissipation method: Thermal conduction cooling (fanless)

Protection level IP30 (dustproof)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

60M100-00

Application areas:

In high-precision manufacturing environments, motion control is crucial, and 60M100-00 has become the cornerstone of seamless automation. This module is designed specifically for industries such as semiconductor manufacturing, medical device assembly, and advanced robotics technology, meeting the market’s demand for ultra reliable and high-speed motion control systems. For example, in semiconductor wafer processing, it coordinates the precise motion of the robotic arm to position the wafer within nanometer level tolerances, ensuring zero defects during lithography or inspection processes. Its powerful error correction and real-time feedback capabilities make it indispensable in scenarios where small deviations may lead to high material waste or production delays.

In medical device manufacturing, the 60M100-00 performs well in managing complex assemblies of microfluidic devices or implantable components. Its multi axis motion synchronization capability (such as precise linear slides and rotating platforms) can create complex, sterile environments, ensuring consistency. Engineers trust its integration capability with visual systems and force sensors to achieve adaptive control based on real-time process changes. As a core component of industrial automation, the 60M100-00 is widely used in closed-loop control systems, making it an ideal choice for applications that require speed and sub micron precision.

Related products:

60M200-00- Supports 32 axes and is suitable for large robot units.

60I050-00- I/O expansion module with 32 digital inputs/outputs for sensor integration.

60D040-00- Dual axis servo drive module, designed for close synchronization with 60M100-00.

60150-00- Safety Controller Module, achieving STO (Safe Torque Off) compliance in collaborative robots.

60H080-00- Human Machine Interface (HMI) panel, plug and play with 60M100-00.

60C030-00- Encoder interface module, supporting absolute and incremental feedback devices.

60P024-00- Redundant power supply unit to improve system reliability in critical applications.

Installation and maintenance:

Before installation, ensure that the control cabinet complies with EMC guidelines and separate the power and signal lines to reduce interference. 60M100-00 requires a dedicated grounding path with a grounding resistance of<1 Ω to prevent voltage spikes. During installation, leave at least 20 millimeters of clearance on all sides for air circulation, even though the module is fanless in design. Verify whether the power supply can provide a continuous current of at least 2A to meet peak loads during rapid acceleration.

In terms of maintenance, conduct a visual inspection every quarter to check for loose connections or signs of thermal stress on the PCB. Use built-in diagnostic software to view error logs and monitor motor performance indicators such as harmonic distortion and speed ripple. Firmware updates should be performed during planned downtime and existing program files should be securely backed up. For high dust environments, clean the ventilation openings of the casing with compressed air (≤ 5 bar) every six months to ensure efficient heat dissipation.

BENTLY brand other product models:

BENTLY 3500/15 106M1079-01 large truck

Bently 135031-01 small card

Bently 135031-01 small card

BENLTY 135489-02

BENTLY 3500/22M 288055-01 large truck

BENTLY NEVADA 167699-02

BENLTY 1701/25

Bently 3701/55 323174-01

Bently 1900/65A

Bently 1900/65A

Bently 1900/65A-01-01-03-00-00

Bently 1900/65A-01-01-03-00-00

Bentley 176449-03

Bentley 140734-03

Bentley 3500/22-01-01-R0

BENTLY 3500/91M 190782-01

BENTLY 3500/22-01-01-R0

BENTLY 3500/01-01

BENTLY 3500/93 135785-01

BENTLY 1900/65A-01-01-01-00-00

BENTLY 3500/65-01-00 145988-02

BENTLY 3500/91M 190782-01

BENTLY 24765-01-01

BENTLY 1900/65A-00-00-01-00-01 screen

BENTLY 3500/22M 288055-01 new large truck model

BENTLY 3500/22M 146031-01 small card

BENTLY 3500/22M 123M4610 new cable

BENTLY 3500/93 135785-02C

BENTLY 330101-00-12-10-02-00

BENTLY 330106-05-30-10-02-05

Bently 330130-045-00-05

BENLTY 330130-045-01-05

BENTLY 330130-080-01-05/CN

BENTLY 330180-51-05

BENTLY 330180-51-05

Bently version 01S 3500/15 127610-01 large card

Bently version 01M 3500/32 125712-01 large card

Bently version 02U 3500/42M 176449-02 large card

Bently version 01AC 3500/22M 138607-01 large card old model

Bently version 01L 3500/92 136180-01 large card

Bently version 01G 3500/94 145988-01 large card

Bently 3500/15 125840-02 small card

Bently 3500/94 147663-01 small card

Bently 3500/92 136188-01 small card

Bently 3500/42 140471-01 small card

Bently 3500/32 125720-01 small card

Bently 3500/22M 146031-01 small card

Bently 3500/05-01-03-00-00-00

BENTLY 161216-01

BENLTY 330180-91-CN

BENLTY 330750-40

BENLTY 330851-02-000-060-10-00-CN

BENLTY 330851-02-000-060-10-00-CN

BENTLY 330930-060-01-00

BENTLY 330930-060-01-00

BENTLY 330851-02-000-060-10-00-00

BENTLY TK3-3E

BENLTY 3500/05-01-01-00-00-01

BENLTY 3500/15-02-02-00

BENTLY 3500/15-07-07-02

Bently 3500/15-07-07-02

Bently 3500/20 125744-02W large truck

Bently 3500/20 125744-02W large truck

BENLTY 3500/22-01-01-01

Bently 3500/22M 146031-01 small card

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626