Description

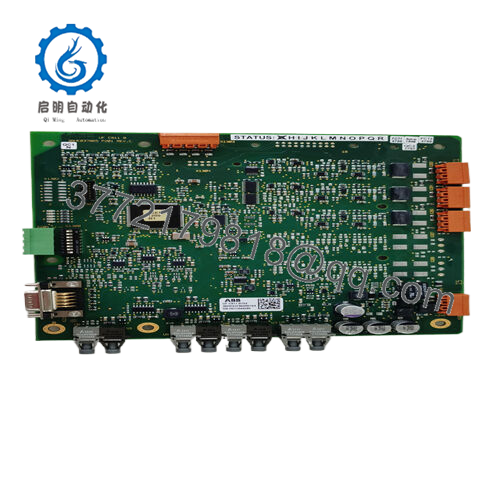

3BHE037864R0104 Product Introduction:

3BHE037864R0104 is an industrial automation control module produced by ABB, which is one of the core components of its industrial control systems such as DCS or PLC. This product is widely used in industrial fields such as energy management, process control, power, petrochemicals, metallurgy, etc. It is mainly used to achieve functions such as signal processing, logic control, data communication, and equipment monitoring in industrial processes.

Technical specifications:

Input voltage: 24V DC (industrial standard), supports wide voltage range input, compatible with various power fluctuation scenarios.

Working temperature: -20 ° C to+70 ° C Suitable for extreme environmental requirements.

Protection level: IP30 or higher, with dust-proof and moisture-proof capabilities.

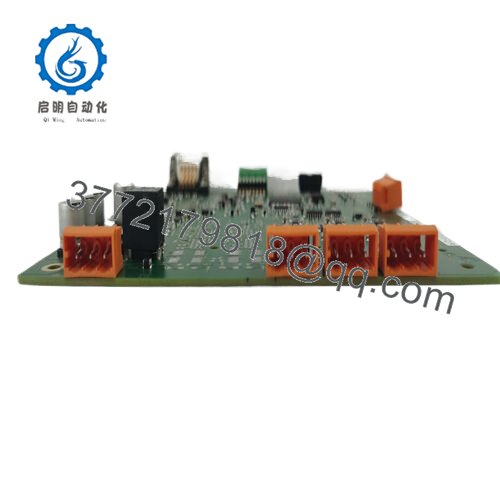

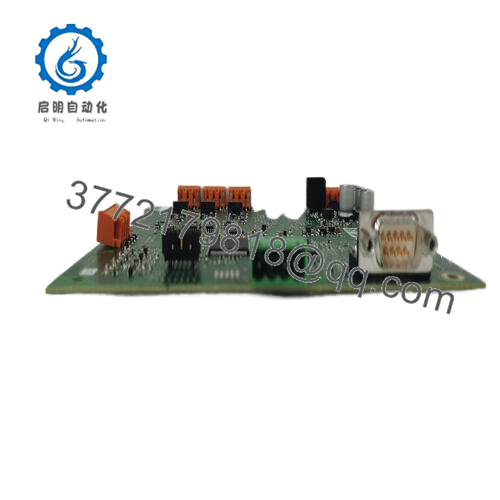

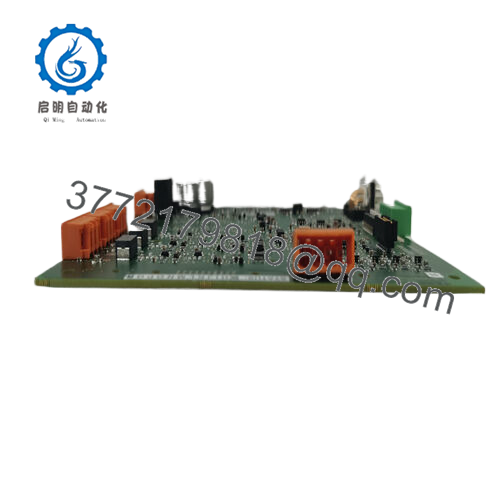

Installation method: Supports 35mm DIN rail installation, easy to integrate into industrial control cabinets.

Communication speed: Supports multiple speeds, such as 9.6kBit/s to 12MBit/s (Profibus DP bus standard).

Size and weight: Compact design for easy installation and maintenance.

contact us:

Mobile:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

Main features and advantages:

As the core control unit of industrial processes, 3BHE037864R0104 has the capabilities of signal processing, logic control, and communication interface management. It can process various input signals (such as sensor data, switch signals, etc.) on the industrial site in real time, and output control commands according to preset logic to drive actuators or equipment operation. Adopting industrial grade design standards, it has high reliability and stability, and can operate stably for a long time in harsh industrial environments. Its protection level complies with industrial dust and moisture resistance standards, and is suitable for complex environments such as high temperature, low temperature, high humidity, and vibration. Supports multiple communication protocols, such as Profibus, Modbus, CAN bus, etc., and can seamlessly connect with different types of industrial equipment to achieve fast data transmission and sharing.

Equipped with Ethernet interface, it supports remote management and monitoring, facilitating system configuration, fault diagnosis, and data analysis for users. Supporting industrial bus expansion, users can flexibly add I/O modules, communication modules, or other functional modules according to actual needs to meet industrial control requirements of different scales and complexities. Equipped with an embedded high-performance industrial grade processor, it has powerful data processing capabilities and can respond in real-time to complex control tasks.

Support large capacity storage, which can save system configuration, historical data, and real-time operation logs, ensuring data integrity and traceability. Provide multiple digital signal input/output (DI/DO) interfaces to adapt to various sensors and actuators.

Support high-precision analog signal input/output (AI/AO) to meet the precise control requirements for continuous variables such as temperature, pressure, and flow rate.

Application areas:

Energy management: automation control of power plants and substations.

Process control: monitoring and optimization of production processes in industries such as chemical, petrochemical, and pharmaceutical.

Power industry: grid dispatching, distribution automation.

Metallurgy and Mining: Production Line Automation, Equipment Monitoring.

Water treatment: automation control of sewage treatment plants and water supply systems.

Installation and maintenance:

Preparation before installation:

The working temperature range of 3BHE037864R0104 is -10 ° C to 70 ° C, with a wide temperature range of -40 ° C to+85 ° C. During installation, ensure that the ambient temperature is within this range to avoid damage to the equipment due to overheating or overcooling. The relative humidity should not exceed 90% (without condensation). High humidity environments may cause internal components of equipment to become damp, affecting performance. The enclosure protection level is IP30, suitable for indoor installation. It should be avoided to use in dusty, corrosive gas or liquid environments.

Maintenance suggestion:

Regularly inspect the 3BHE037864R0104 casing for any damage, deformation, or corrosion. If there are any abnormalities, they should be dealt with promptly. Check if the power and signal lines are securely connected, and if there are any loose or poor contacts. Ensure good heat dissipation of the device and unobstructed ventilation openings. Regularly clean the dust on the surface of the equipment to prevent it from affecting heat dissipation. Regularly test whether the power input is normal and whether the voltage is stable. Check whether the signal input and output are normal, and whether the analog and digital signals are accurate. Test whether the alarm function of the equipment is normal, such as fiber link failure and power failure alarm output. Regularly clean the surface and interior of the equipment to prevent dust accumulation from affecting equipment performance. When the equipment malfunctions, first check whether the power and signal connections are normal, and then gradually investigate other possible causes. If the fault cannot be solved by oneself, professional maintenance personnel should be contacted in a timely manner for repair to avoid further damage caused by improper operation.

Other product models of ABB series:

ABB 3HAC029032-004

ABB 3HAC029818-001

ABB 3HAC031977-001

ABB 3HAC037281-001

ABB 3HNE00313-1

ABB 4LA41100102V1.2

ABB 500BIO01 1MRB150005R1/J

ABB 500BIO01 1MRB150005R1/K

ABB 500CIM05 1MRB150077R1/B

ABB 500CPU05 1MRB150081R1/E

ABB 500PSM03a 1MRB150038R1

ABB 500PSM03a 1MRB150038R1

ABB 500SCM01 1MRB200059/C 1MRB15004R0001

ABB 5304-MBP-PDPMV1

ABB 560CMD11 1KGT023400R0001

ABB 560CMU04 1KGT011300R0001

ABB 5SDF0860H0003

ABB 5SDF1045H0002

ABB 5SGX1445H0001

ABB 5SHX0360D0001 3BHL000384P0101

ABB 5SHX0660F0001 3BHB003387R0101

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626