Description

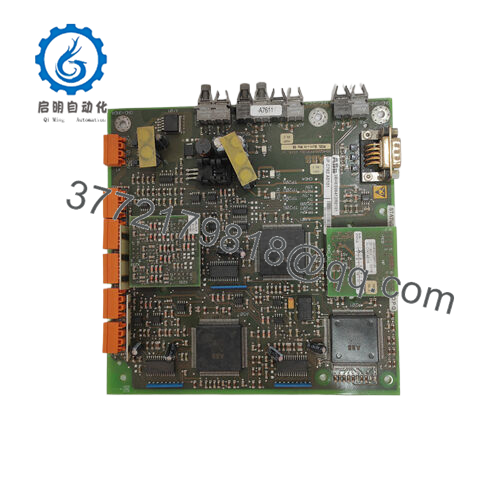

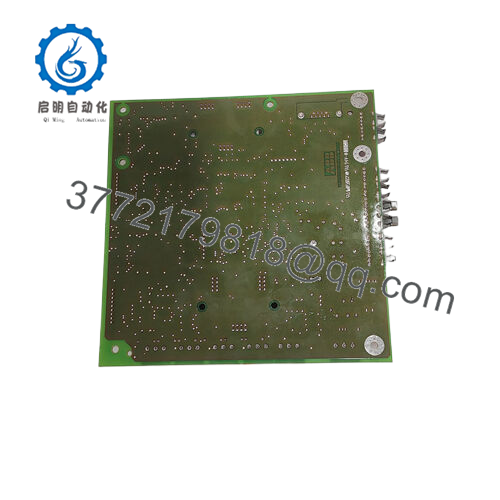

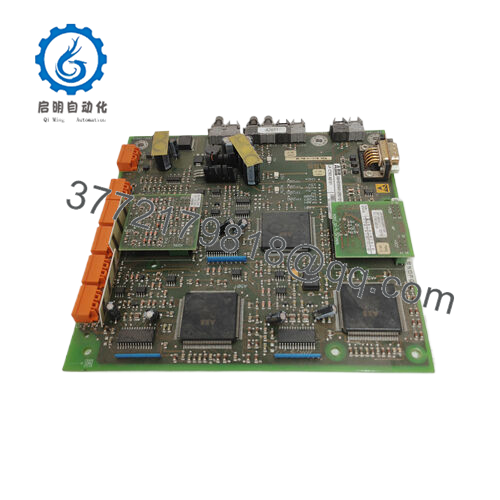

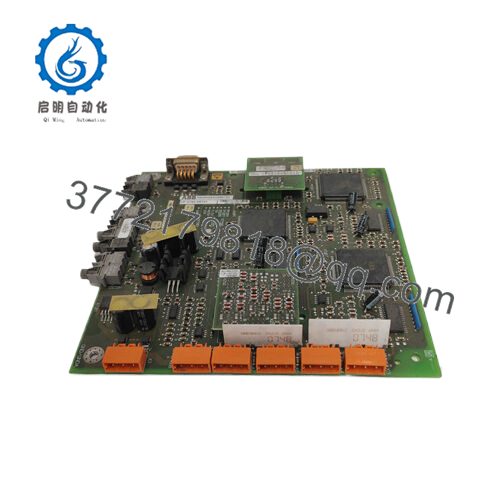

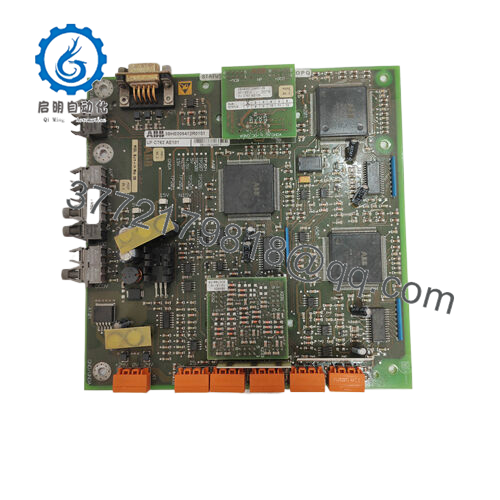

3BHE006412R0101 UFC762AE101 Product Introduction:

Description:

3BHE006412R0101 UFC762AE101 is a high-performance industrial automation control module produced by ABB, belonging to ABB’s control system series. This module is designed specifically for industrial automation scenarios, integrating data processing, signal control, and communication functions to achieve precise control, real-time monitoring, and system integration of electromechanical equipment.

3BHE006412R0101 UFC762AE101

Technical specifications:

Brand: ABB

Model: 3BHE006412R0101 UFC762AE101

Type: High performance industrial automation control module

Input signal: Supports various input methods such as analog (0-10V, 4-20mA), digital (ON/OFF), pulse signal, etc.

Output signal: Supports various output modes such as analog (0-5V, 4-20mA), digital (relay/SSR drive), pulse output, etc.

Control accuracy: ± 0.1% FS (some sources display ± 0.2% F.S ± 1 word), ensuring high-precision control.

Power supply voltage: Supports AC 100-240V (50/60Hz) or DC 24V ± 2V, suitable for different power supply environments.

Working temperature: -10 ° C to+55 ° C, suitable for a wide range of industrial environmental temperatures.

Power consumption: ≤ 2W (some models), energy-saving and efficient.

Dimensions: 144mm × 144mm × 102mm (some models are 100 × 112 × 45mm), compact design for easy installation.

Installation method: Supports DIN 35 rail installation or wall mounted installation, flexibly adapting to different installation needs.

Protection level: IP20 (some models support higher protection), effectively resisting dust and moisture.

Material: Combination of metal and plastic, lightweight design, weighing approximately 0.62 pounds to 1.5kg.

3BHE006412R0101 UFC762AE101

contact us:

Mobile:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

Main features and advantages:

3BHE006412R0101 UFC762AE101 can accurately adjust the speed of the servo motor to meet different working conditions. Supports high-precision positioning and is suitable for motion control scenarios that require precise trajectories. Real time adjustment of output torque ensures the stability and safety of equipment operation. Supports simultaneous control of multiple servo motors, suitable for high-precision motion control of multi axis linkage, such as robots, CNC machine tools, and other equipment. Equipped with an encoder interface, it can connect to the encoder of the servo motor to achieve position feedback and closed-loop control, improving control accuracy and dynamic response capability. Supports multiple communication protocols such as Ethernet, Modbus, CAN bus, etc., facilitating data exchange and communication with other devices and control systems, and achieving system integration. Adopting industrial grade design, it has high anti-interference ability and stability, and can adapt to various harsh industrial environments.

Designed for durability and stable operation, suitable for long-term work and harsh conditions in industrial environments. Equipped with a 32-bit processor that supports high-speed data processing, ensuring real-time control response. Built in Ethernet, USB, and multiple serial ports (RS232/RS485), supporting device networking and remote monitoring. Adapt to harsh industrial environments (wide temperature range, anti vibration), with self diagnosis and fault protection functions. Supports position, speed, and torque control, suitable for servo systems. Real time analysis of sensor signals, execution of control algorithms, and output of instructions. Can connect devices such as PLC, servo motors, sensors, etc. to achieve automated process management.

3BHE006412R0101 UFC762AE101

Application areas:

The ABB UFC762AE101 3BHE006412R0101 CPU module is widely used in various industrial automation fields due to its high performance, high reliability, and flexible communication capabilities, such as:

Process industry: In the petrochemical, natural gas, pharmaceutical, food and beverage process industries, ABB UFC762AE101 3BHE006412R0101 can be used to control various process flows, such as precise control of temperature, pressure, flow rate, as well as complex sequential control and batch management.

In the power industry, ABB 3BHE006412R0101 UFC762AE101 can be used for boiler control, turbine control, auxiliary equipment control, and substation automation in power plants and transmission and distribution systems, ensuring the safe and stable operation of the power system.

Manufacturing: In discrete manufacturing industries such as automobile manufacturing, metal smelting, and papermaking, ABB 3BHE006412R0101 UFC762AE101 can be used to control production lines, robots, conveyor systems, etc., achieving automation and optimization of production processes.

Water treatment industry: In water and sewage treatment plants, ABB 3BHE006412R0101 UFC762AE101 can be used to control water pumps, valves, dosing systems, etc., achieving automated management of the water treatment process.

3BHE006412R0101 UFC762AE101

Installation and maintenance:

Installation preparation:

Ensure that the installation environment temperature is between -10 ° C and+55 ° C to avoid the impact of extreme temperatures on module performance. The relative humidity should be controlled between 5% and 95% (without condensation) to prevent moisture from entering and causing short circuits or corrosion. The site and control room should be properly isolated and regularly cleaned to prevent dust from having adverse effects on component operation and heat dissipation. Try to avoid interference from strong electromagnetic fields on the system, avoid operating stations, displays, etc. during movement, and avoid pulling or damaging equipment connection cables and communication cables. Ensure stable power supply voltage within the range of AC 100-240V (50/60Hz) or DC 24V ± 2V as required by the module.

PLCs should be kept away from strong interference sources such as welding machines, high-power silicon rectifiers, and large power equipment, and should not be installed in the same switchgear as high-voltage electrical appliances. The transmission of analog signals should use shielded wires, and the shielding layer should be grounded at one or both ends. The grounding resistance should be less than 1/10 of the shielding layer resistance to reduce electromagnetic interference.

Maintenance suggestion:

During installation, debugging, and maintenance operations, relevant safety operating procedures and ABB user manuals should be strictly followed. Before performing any maintenance operations that may affect the operation of the module, the power should be cut off and appropriate safety measures should be taken. Regularly check the hardware status of the module, including surface cleanliness, no oil stains on the printed board inserts, and no abnormalities after slight tapping. Regularly conduct software loading and unloading tests to ensure the normal operation of communication ports and manual control stations, as well as the normal operation of various analog and switch input and output channels. Utilize the self diagnostic function of the module to detect system faults in real-time and generate alarms, and take timely maintenance measures.

3BHE006412R0101 UFC762AE101

Other ABB brand products:

ABB 745745

ABB 746376

ABB 07AC91

ABB 07KR31 FPR36000227R1202-O

ABB 07KT92

ABB 07KT92 GJR5250500R0202

ABB 07KT93 GJR5251300R0101

ABB 07KT94 GJR5252100R3261

ABB 07kt94g GJR5252100R0261

ABB 07KT94-S H3 GJR5252100R2201

ABB 07KT98 GJR5253100r0272

ABB 07KT98 GJR5253100R0272

ABB 07KT98 GJR5253100R0272

ABB 07MK92 GJR5253300R1161

ABB 086318-002

ABB 1MRB150005R1/P

ABB 1MRK000005-380 REG670

ABB 1MRK000508-BD

ABB 1MRK000508-CDr09

ABB 1MRK002122-ABR02

ABB 1MRK002238-CA

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626