Description

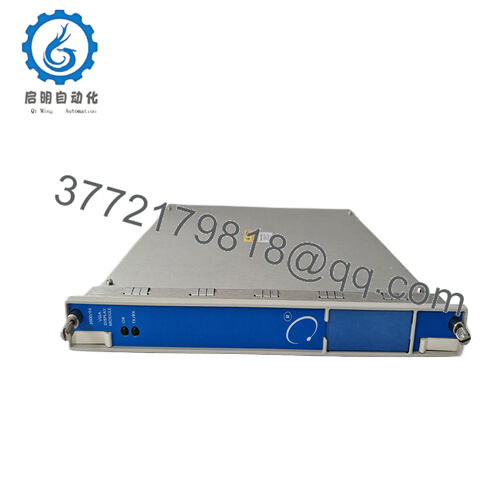

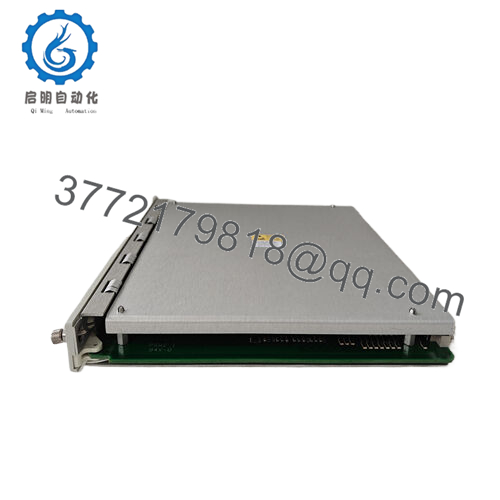

BENTLY 350094M 184826-01 is an advanced BENTLY 3500 monitoring system for shaft centering and vibration analysis module. This module works in conjunction with the 3500 rack and other modules such as vibration monitors and communication gateways, focusing on mechanical alignment and dynamic motion analysis. Unlike the general vibration module, this model has dual function optimization: it can measure axis alignment parameters and analyze vibration characteristics to locate the root cause of alignment deviation.

350094M 184826-01

350094M 184826-01 simplifies the alignment process, eliminating manual calculations and guessing. Its software driver interface provides step-by-step alignment guidance, real-time graphical display of alignment errors (such as horizontal/vertical offset, angle deviation), reduces installation time for new devices by up to 50%, and lowers the risk of human error in complex alignment tasks.

350094M 184826-01

Main features and advantages:

Precision measurement capability

Dual axis alignment: Measure radial (offset) and axial (angle) deviations with sub millimeter accuracy using laser transceivers or optical sensors.

Vibration analysis: Supports FFT (Fast Fourier Transform) and time-domain vibration analysis to identify frequency domain issues related to alignment deviation (such as resonance and bearing defects).

Real time graphical display: real-time XY curve of shaft movement, vibration amplitude trend chart and polar coordinate chart of dynamic alignment adjustment.

Industrial grade hardware design

Durable and sturdy: It can operate within a temperature range of -40 ° C to 85 ° C, withstand 5g vibration, and is suitable for harsh environments such as engine testing rooms or offshore platforms.

Modular compatibility: seamlessly embedded in the 3500 rack (slots 9-14), sharing power and data buses with other modules to achieve a unified monitoring solution.

On site upgradable: Supports firmware updates through USB or Ethernet, adding new sensor protocols or analysis functions.

Workflow optimization

Alignment Guide: Step by step software guidance simplifies complex alignment tasks, making it easy for even operators with limited technical experience to operate.

Data recording: Store centering reports and vibration trends, support historical analysis, and achieve predictive maintenance planning.

Multi protocol communication: Integrate with PLC (such as Allen Bradley, Siemens) through Modbus TCP or Ethernet/IP, and connect the data to the entire plant control system.

Long term reliability

Redundant power input: Dual 24 VDC input ensures continuous operation during transient power fluctuations.

MTBF rating: Over 150000 hours, verified by BENTLY’s rigorous industrial durability testing.

350094M 184826-01

Technical specifications:

Model 350094M 184826-01

Brand BENTLY

Type axis alignment and vibration analysis module

Power supply 18-32 VDC (dual input)

Working temperature -40 ° C to 85 ° C

Installation method: 3500 rack (standard 3U height)

Dimensions: 146 mm (width) x 261 mm (height) x 330 mm (depth)

Weight 2.8 kg

Support sensor laser alignment tool, proximity sensor, accelerometer

Communication protocols Ethernet/IP, Modbus TCP, RS-485

Certified UL, CE, CSA, API 670 (vibration monitoring)

Analysis tools FFT, time-domain waveform, orbit diagram, alignment deviation report

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

350094M 184826-01

Application areas:

In aerospace assembly lines, this module ensures micrometer level alignment accuracy between the turbine shaft and gearbox, avoiding early wear or catastrophic failures during flight testing. In energy facilities, it can monitor the vibration of reciprocating compressors and detect the risk of high-pressure system leakage or mechanical failure caused by alignment deviation.

The core value of this module lies in its ability to address the critical challenge of maintaining mechanical alignment in harsh, high vibration environments. By integrating with laser alignment tools and proximity sensors, it can provide real-time feedback on axis offset, angle deviation, and dynamic vibration modes, making it an essential tool for engineers to debug new equipment, perform routine maintenance, or troubleshoot mechanical faults.

350094M 184826-01

Related products:

BENTLY 350040M proximity sensor monitor – provides vibration displacement data and correlation analysis with alignment indicators.

BENTLY 350022M Speed/Trip Monitor – Synchronizes centering data with speed for dynamic analysis.

BENTLY 350015 Communication Gateway – Export alignment reports to enterprise systems via OPC UA.

BENTLY 350032 TSI Modular Rack – Physical enclosure, supports integrated installation with other 3500 modules.

BENTLY 177120-01 Laser Alignment Tool – directly interfaces with 350094M to provide real-time alignment feedback.

Installation and maintenance:

Preparation before installation

Rack configuration: Ensure that the 3500 rack has available slots (recommended slot 10 for dedicated centering tasks) and is properly grounded to reduce EMI interference.

Sensor calibration: Use the BENTLY 2080 Plus calibration kit to pre calibrate the laser alignment tool or proximity sensor.

Cable wiring: Separate the sensor cable (low voltage) from the power cable to avoid interference with precision measurements.

Maintenance suggestions

Quarterly inspection: Verify sensor connections and module firmware versions (ensure compatibility with the 3500 system operating system).

Annual calibration: Use traceable standards to recalibrate sensors and maintain measurement accuracy.

Data backup: Regularly archive alignment reports and vibration trends to a secure server for compliance and historical analysis.

BENTLY Other product models

BENTLY 84661-50

BENLTY 3500/92-04-01-01

BENLTY 3500/70-01-00(176449-09+140471-01)

BENLTY 176449-03

BENTLY 330881-28-08-120-00-02

BENTLY 330881-28-08-060-00-02

BENTLY 990-04-ХХ-01-05 165335-01

BENLTY 3500/91M 190782-01

BENLTY 3500/61 163179-02

Bently Nevada 3500/50-04-002

BENLTY 3500/25M-02-02

BENLTY 3500/42M-04

BENLTY 3500/33-01-01

BENLTY 3500/92-04-01

BENLTY 3500/45 176449-04

BENLTY 2300/20-00

BENLTY 2300/20-00

BENLTY 2300/20-00

BENLTY 3500/22-01-01-R0

BENLTY 3500/92-04-01-R0

BENLTY 330851-02-000-060-10-00-00

BENLTY 3500/65 172103-01 small card

BENLTY 3500/22M 288055-01 Large Card

BENLTY 3500/40M 176449-01 Large Card

BENLTY 3500/65 145988-02 Large Card

Bently 3500/54 133396-01

Bently 3500/54 286566-01

BENLTY 3500/22-01-01-00

BENLTY 3500/22-01-01-00

BENLTY 3500/92-04-01-R0

BENLTY 3500/15-05-05-R0 front and rear card set

BENLTY 3500/62 136483-01

BENLTY 330103-00-03-05-02-05

BENLTY 3500/22 288055-01

BENLTY 3500/22 288055-01 large truck

BENTLY 3500/62 136483-01 small card

BENLTY 161216-01

BENLTY 3500/44M 140734-03 Large Card Version 03B

Bently 3500/65 145988-02

BENLTY 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

BENLTY 330877-080-37-00

Bently Nevada 3500/15-05-05-R0

BENLTY 2300/20-00

BENLTY 3500/15127610-01 large card

Bently Nevada 3500/15-05-05-R0

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/42 176449-02

BENTLY 3500/42M 176449-02 large card

Bently Nevada 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

BENLTY 74712-06-05-04-00

BENLTY 3500/92-01-01-00

BENLTY 3500/15 set

BENLTY 3500/92

BENLTY 3500/92-01-01-00

BENLTY 3500/42-01-02-R0

BENLTY 3500/32-02-R0

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626