Description

350091-02-00 190782-01 is a dual channel vibration and process monitoring module, belonging to the [brand] 3500 series – which is the industry benchmark for mechanical health management. As an interface between on-site sensors (such as accelerometers, proximity probes) and control systems, this module provides real-time analysis capabilities to optimize equipment reliability and process efficiency.

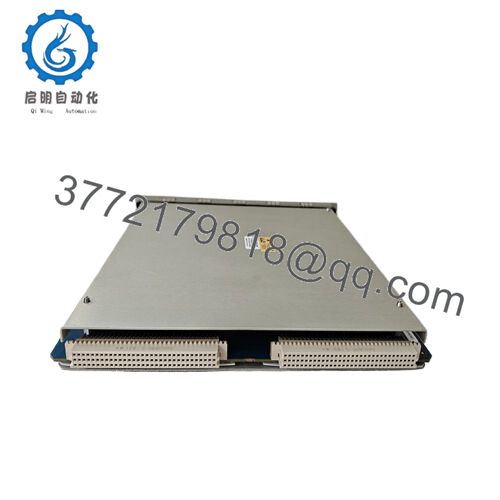

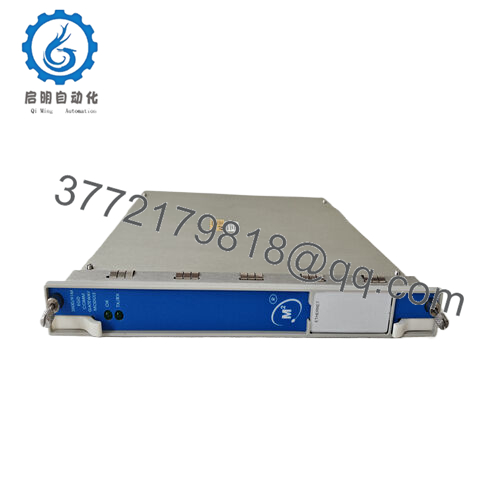

350091-02-00 190782-01

This module adopts an expandable design and supports configurable input types (IEPE, thermocouple,…) LVDT), And it can be seamlessly integrated into distributed control architecture. Its modular design allows engineers to mix vibration and process measurement in one unit, reducing hardware complexity and wiring costs. For system integrators, their native support for EtherNet/IP, Profibus DP, and Modbus TCP protocols ensures plug and play compatibility with traditional PLCs and modern cloud platforms such as AWS IoT or Microsoft Azure.

The uniqueness of 350091-02-00 190782-01lies in its predictive intelligence. The advanced FFT algorithm can analyze the vibration spectrum in real-time, identify fault modes (such as misalignment and cavitation) with 95% accuracy, and proactively solve problems before they escalate. This forward-looking approach can minimize unplanned downtime, reduce maintenance costs by up to 30%, and extend equipment lifespan.

350091-02-00 190782-01

Main features and advantages:

Ultra precision data collection

24 bit ADC and synchronous sampling (up to 10 kHz/channel) ensure extremely low noise and distortion, which is crucial for detecting subtle anomalies in rotating machinery.

The dual channel design supports simultaneous monitoring of vibration and temperature, making it suitable for multi parameter analysis of complex systems.

Industrial grade durability

The IP67 casing is dustproof, waterproof, and capable of high-pressure flushing, and has an impact resistance (50g peak) that can withstand heavy mechanical environments.

The wide temperature range (-40 ° C to+85 ° C) and EMI/EMC compatibility (IEC 61000-6-2) ensure reliability under extreme conditions.

Flexible connectivity and integration

Multi protocol support (EtherNet/IP, Profibus DP, Modbus TCP) can be seamlessly integrated into PLCs, HMIs, and cloud platforms.

Redundant power input (18-32 V DC) and hot swappable design ensure zero downtime during maintenance or system upgrades.

Long term reliability

The built-in self diagnostic function can monitor the health status of hardware and mark issues such as loose connections or sensor drift.

10-year lifecycle support can reduce the risk of obsolescence, and firmware updates can enhance functionality and security over time.

350091-02-00 190782-01

Technical specifications:

Model 350091-02-00 190782-01

Brand BENTLY

Type: Dual channel vibration and process monitoring module

Input channel 2 x configurable (IEPE/TC/LVDT)

Sampling rate up to 10 kHz/channel

Communication protocols EtherNet/IP, Profibus DP, Modbus TCP

Power supply 18-32 V DC (dual redundant input)

Dimensions: 100mm (width) x 150mm (height) x 60mm (depth)

Installation method: DIN rail or panel installation

Certified CE, UL, ATEX (Zone 2) IECEx

Environmental protection level IP67, IEC 61000-6-2 (EMC)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

Application areas:

In petrochemical plants, this module can monitor the operating status of high-speed compressors and pumps, and detect signs of imbalance or bearing degradation in advance through advanced vibration analysis technology. Its compatibility with traditional and modern control systems (such as DCS, SCADA, IIoT platforms) enables it to both upgrade old infrastructure and support cutting-edge digital transformation plans.

In steam turbine power plants, this module can achieve micrometer level accuracy in measuring shaft displacement, thermal expansion, and axial position, helping engineers proactively adjust maintenance plans and avoid catastrophic failures. The automotive assembly line utilizes its multi-channel function to monitor robot welding, conveying systems, and quality control sensors, ensuring production consistency and reducing defect rates.

Related products:

350091-04-00-4 channel version, suitable for multi machine monitoring

350092-02-00- High temperature model (+125 ° C maximum), suitable for furnaces

350040M – Proximity Probe Interface Module (Complementary Sensor Pairing)

350022M – Single channel vibration monitoring module, suitable for basic applications

350033- TSI (Total Station Interface) module, suitable for process integration

Installation and maintenance:

Installation instructions and maintenance best practices

Before installation:

Installed in a grounded and climate controlled cabinet, with a distance of no more than 3 meters from the monitoring asset, to reduce signal delay.

Use shielded twisted pair cables to connect sensors and separate power and control wiring to reduce EMI.

Verify the stability of the power supply and equip it with surge protection, especially in areas with significant voltage fluctuations.

maintain:

Quarterly: Check if the connections are corroded or loose; Adjust the installation torque of the DIN rail to 2.5 N · m.

Every six months: Run self diagnostic tests through the module’s web interface to check ADC accuracy and communication latency.

Annually: Calibrate according to traceable standards (such as the National Institute of Standards and Technology in the United States) to ensure compliance.

Firmware: updated quarterly to obtain new features (such as AI driven fault detection); Test in a non production environment first.

BENTLY Other product models

BENTLY 84661-50

BENLTY 3500/92-04-01-01

BENLTY 3500/70-01-00(176449-09+140471-01)

BENLTY 176449-03

BENTLY 330881-28-08-120-00-02

BENTLY 330881-28-08-060-00-02

BENTLY 990-04-ХХ-01-05 165335-01

BENLTY 3500/91M 190782-01

BENLTY 3500/61 163179-02

Bently Nevada 3500/50-04-002

BENLTY 3500/25M-02-02

BENLTY 3500/42M-04

BENLTY 3500/33-01-01

BENLTY 3500/92-04-01

BENLTY 3500/45 176449-04

BENLTY 2300/20-00

BENLTY 2300/20-00

BENLTY 2300/20-00

BENLTY 3500/22-01-01-R0

BENLTY 3500/92-04-01-R0

BENLTY 330851-02-000-060-10-00-00

BENLTY 3500/65 172103-01 small card

BENLTY 3500/22M 288055-01 Large Card

BENLTY 3500/40M 176449-01 Large Card

BENLTY 3500/65 145988-02 Large Card

Bently 3500/54 133396-01

Bently 3500/54 286566-01

BENLTY 3500/22-01-01-00

BENLTY 3500/22-01-01-00

BENLTY 3500/92-04-01-R0

BENLTY 3500/15-05-05-R0 front and rear card set

BENLTY 3500/62 136483-01

BENLTY 330103-00-03-05-02-05

BENLTY 3500/22 288055-01

BENLTY 3500/22 288055-01 large truck

BENTLY 3500/62 136483-01 small card

BENLTY 161216-01

BENLTY 3500/44M 140734-03 Large Card Version 03B

Bently 3500/65 145988-02

BENLTY 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

BENLTY 330877-080-37-00

Bently Nevada 3500/15-05-05-R0

BENLTY 2300/20-00

BENLTY 3500/15127610-01 large card

Bently Nevada 3500/15-05-05-R0

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/42 176449-02

BENTLY 3500/42M 176449-02 large card

Bently Nevada 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

BENLTY 74712-06-05-04-00

BENLTY 3500/92-01-01-00

BENLTY 3500/15 set

BENLTY 3500/92

BENLTY 3500/92-01-01-00

BENLTY 3500/42-01-02-R0

BENLTY 3500/32-02-R0

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626