Description

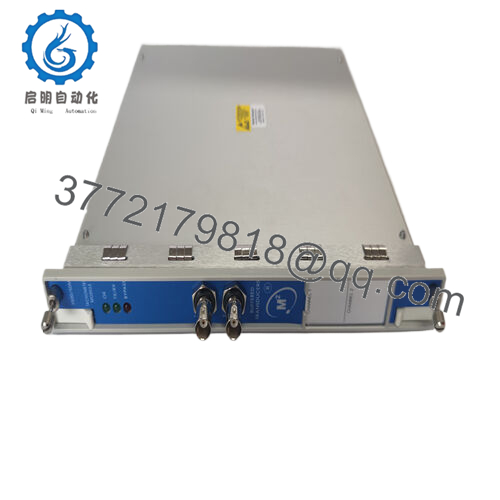

The 3500/50M tachometer module is designed to seamlessly integrate into industrial automation architecture. It can be connected to various control platforms, serving as a key link between rotating machinery and the entire control system.

3500/50M

This module is compatible with the backplane system, which is crucial for distributing power and data between different components in industrial environments. In terms of input/output architecture, the 3500/50M is capable of receiving input signals from speed sensors such as proximity probes or magnetic pickups. Then, it processes these signals and provides accurate speed data to the control system. In addition, it also supports multiple communication protocols, making it easy to connect with other devices in the automation network. This ensures that speed information can be effectively shared and used throughout the entire industrial ecosystem.

3500/50M

Technical specifications:

Model 3500/50M

Brand Bently Nevada

Type tachometer module

Input voltage to obtain power from the system

Working temperature range -20 ° C to 60 ° C

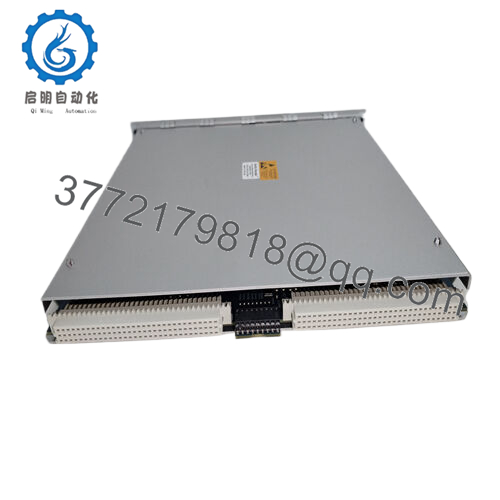

Installation method: Rack mounted installation

Size 9.50 inches x 0.96 inches x 9.52 inches

Weight 0.82 kilograms

Interface/bus provides multiple communication interfaces for connecting control systems

Compliance with relevant industry standards (CE safety and EMC compliance standards)

Support industry standard communication protocols for seamless integration

Typical power consumption of 8.0 watts

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3500/50M

Main features and advantages:

The Bentley Nevada 3500/50M tachometer module is designed for seamless integration into industrial automation architecture. It can be connected to various control platforms, serving as a key link between rotating machinery and the entire control system. This module is compatible with the backplane system, which is crucial for distributing power and data between different components in industrial environments. In terms of input/output architecture, the3500/50M is capable of receiving input signals from speed sensors such as proximity probes or magnetic pickups. Then, it processes these signals and provides accurate speed data to the control system. In addition, it also supports multiple communication protocols, making it easy to connect with other devices in the automation network. This ensures that speed information can be effectively shared and used throughout the entire industrial ecosystem.

This module is designed specifically for harsh industrial environments to ensure long-term performance. The high-quality materials used make it sturdy and durable, capable of withstanding common vibrations, temperature fluctuations, and electrical noise in industrial environments. This durability not only reduces maintenance requirements, but also lowers the risk of unexpected failures, thereby helping to maintain the normal operation time of critical systems. Its advanced signal processing capability ensures consistent performance. By providing accurate and reliable speed data in real-time, it enables operators to make informed decisions quickly. This reduces engineering costs as there is no need for complex and time-consuming manual speed checks. The simple setup program of this module also facilitates easy integration and enables rapid deployment in new or existing industrial systems.

3500/50M

Application areas:

In the power generation industry, it is used to monitor the speed of turbines. Accurate speed control is crucial here to ensure efficient power generation and prevent overspeed or underspeed (which may result in equipment damage and power outages).

In manufacturing, it is used to monitor the speed of motors that drive production machinery.

Accurately monitoring the speed of the spinning machine in textile factories is crucial for maintaining the quality of the produced yarn. 3500/50M also holds significant value in the oil and gas industry.

In the pump station, it helps to monitor the pump speed and ensure stable flow of oil or natural gas in the pipeline. These applications typically require continuous operation, and the reliability of the 3500/50M makes it an ideal choice.

3500/50M

Related products:

Bentley Nevada 3500/50-04-01: This is an industrial programmable logic controller (PLC) module with its own set of functions. It has different focuses in terms of functionality, with specific processor speeds, memory configurations, and input/output channels, suitable for applications that value these features more.

Bentley 3500/50 286566-02: This is an advanced industrial monitoring module designed specifically for vibration monitoring. In applications that require simultaneous speed and vibration monitoring to comprehensively evaluate the health status of mechanical equipment, it can be used in conjunction with the 3500/50M.

Bentley Nevada 3500/51M: This is a model that may have enhanced speed monitoring capabilities or different communication options, making it an upgrade option for users who require more advanced features than the 3500/50M.

Bentley Nevada 3500/45: This module may have different input capability ranges or be designed specifically for different categories of mechanical equipment, providing an alternative solution for applications that do not require specific functions of the 3500/50M.

Bentley Nevada 3500/60: It may be a module with broader monitoring capabilities, integrating other types of measurements in addition to speed measurement, suitable for more complex industrial environments.

Installation and maintenance:

Before installing the Bentley Nevada3500/50M , it is essential to check the compatibility of the communication interface with the existing control system. Ensure that there is sufficient space and power supply for the backboard or installation location. In addition, it is necessary to confirm that the firmware of the module is the latest version to avoid compatibility issues with the control software.

During continuous maintenance, regularly check the status indicator lights on the module. These indicator lights can provide early warning of potential issues. Regularly check the connectors to ensure there are no loose connections, as loose connections may affect the accuracy of speed data. It is recommended to conduct calibration checks at least once a year to ensure that the module continues to provide accurate speed measurements.

BENTLY Other product models

Bently 3500/22M 138607/01 Large Card 01AB Version

BENTLY 3500/22M 138607-01

BENTLY 3500/22M 138607-01AE

BENTLY 3500/22M 138607-01 large card

Bently 3500/22M 146031-01 small card

Bently 3500/22M 288055-01 Large Card

Bently 3500/22M cable

Bently Nevada 3500/33 149986-01

BENTLY 3500/22M 138607-01V

BENTLY 3500/33 149986-01

BENTLY 3500/33 149992-01

BENTLY 3500/33 149992-01 Small Card

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/70M 176449-09

Bently 3500/44M 140734-03 Large Card Version 03S

BENTLY 3500/44M 176449-03

BENLTY 3500/60-05-CN

BENLTY 3500/62 163179-03

Bently 3500/64M 176449-05

BENTLY 3500/72M

BENTLY NEVADA 3500/92 136188-02 Small Card

BENTLY 3500/72M 140734-08

BENTLY 3500/91 161204-01

BENTLY 60M500-00-00

BENTLY 3500/65-01-01(145988-02+172103-01)

Bently TK-3E 177313-02-02

Bently 1900/65A-00-01-01-01-01

BENTLY 3500/40M-01-00

BENTLY 3500/92-04-01-00 (136180-01+136188-02)

BENTLY 86517-01-01-01-02 159840-01

BENTLY 176449-02

BENTLY 3500/22M 288055-01

BENTLY 288055-01

BENTLY 3500/15-02-02-01

BENTLY 3500/92-04-01-00 (136180-01+136188-02)

BENTLEY 3500/65 145988-02 Large Card

BENTLEY 330876-03-50-00-00

Bently 330876-03-90-00-05

Bently 3500/72M 176449-08 large card

Bently 3500/70M 176449-09 large truck

BENTLEY 3500/22M 138607-01 Large Card Old Model

BENTLY 1900/65A-01-01-03-00-01

Bently 149992-01

Bently 3500/45 176449-04 large truck

Bently 3500/42-09-05 128229-01

BENLTY 176449-04

Bently 128229-01 small card

BENLTY 24765-01-01

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626