Description

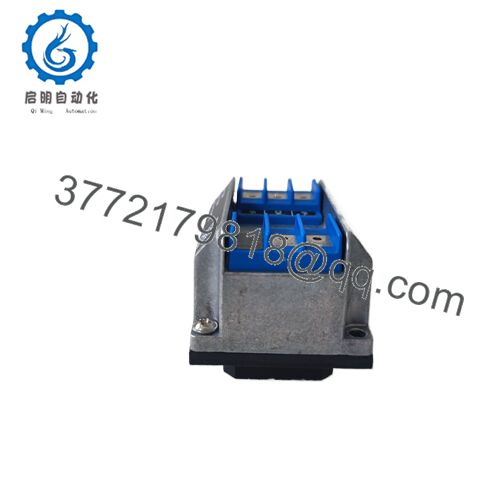

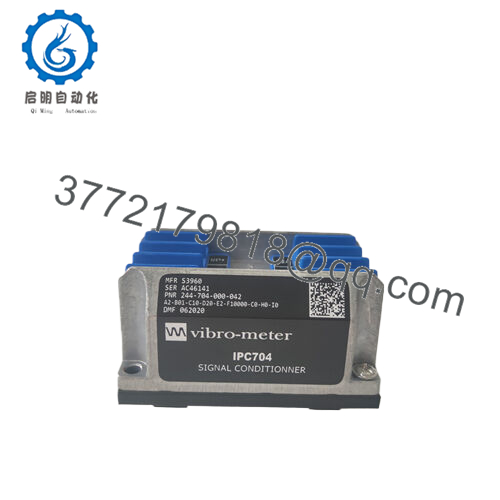

244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0 is a high-performance data acquisition and transmission module designed to become the core hub for data management in industrial automation systems. It can interface with various sensors, including analog temperature and pressure sensors as well as digital proximity sensors, to collect raw data and convert it into standardized formats for seamless transmission.

244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0

This module can be easily integrated into existing control platforms and backplane systems, utilizing popular industrial communication protocols such as Modbus TCP, EtherNet/IP, and Profibus DP. It can process multiple data streams at the same time to ensure that the information from different sensors is accurately and efficiently routed to the corresponding destination, whether it is the central control system, data analysis platform or other connecting devices.

244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0

Technical specifications:

Model 244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0

Brand Vibro meter

Type Data Collection and Transmission Module

Input voltage 24 VDC ± 15%

Working temperature range -40 ° C to 85 ° C

Installation method: DIN rail installation

Size 130mm x 75mm x 45mm

Weight 400g

Interface/Bus Ethernet RS-485、 Analog input, digital input/output

Certified CE, UL, RoHS

Supported protocols Modbus TCP, EtherNet/IP, Profibus DP, OPC UA

Typical power consumption 8W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0

Main features and advantages:

Its large capacity data processing capability ensures that even in complex manufacturing environments with numerous sensors, data can be collected and transmitted without bottlenecks or delays. This helps improve process control as operators can access real-time and accurate data, enabling them to make informed decisions quickly.

This module supports multiple protocols, simplifies system integration, reduces the need for multiple dedicated converters, and lowers engineering costs. Its robust design, wide operating temperature range, and tolerance to environmental factors make it suitable for deployment in the most demanding industrial environments, reducing the frequency of equipment replacement and maintenance.

In addition, the built-in diagnostic function of 244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0 enhances the reliability of the automation system. By early detection and alerting operators of potential issues, it enables proactive maintenance, preventing costly downtime and unplanned shutdowns. Overall, this module helps enterprises improve productivity, reduce operating costs, and maintain a competitive advantage in the field of industrial automation.

244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0

Application areas:

In the automotive manufacturing industry, it can be used to collect data from sensors on assembly lines, such as torque sensors on robotic arms, position sensors on conveyor belts, and quality control sensors. Then transmit these data to the central control system for real-time monitoring and adjustment of the production process, ensuring high precision and quality of vehicle assembly.

In the oil and gas industry, this module can interface with sensors in drilling platforms, pipelines, and refineries to collect data on parameters such as pressure, flow rate, and temperature. It can reliably transmit this data to remote monitoring stations, enabling operators to effectively manage the production process and detect potential leaks or equipment failures in a timely manner.

In the food and beverage industry, hygiene and process consistency are crucial, and 244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0 can collect data from sensors that monitor temperature, humidity, and ingredient levels during the production process. This ensures that the manufacturing process meets strict quality standards and regulatory requirements, maintaining the integrity and safety of the product.

244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0

Related products:

244-704-000-043-A2-B01-C10-D20-E2-F10000-C0-H0-I0: Enhanced version, faster data processing speed, more input channels, meeting more complex data collection needs.

244-704-000-042-A3-B01-C10-D20-E2-F10000-C0-H0-I0: Better protocol compatibility and support for emerging industrial communication standards.

Installation and maintenance:

Before installing 244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0, it is essential to verify the compatibility of the module with existing sensors, control systems, and communication infrastructure. Check the input voltage requirements and ensure that the power supply in the automation system is stable and within the specified range. In addition, check the communication protocol of the connected devices and configure the modules accordingly to ensure seamless data exchange.

For ongoing maintenance, regularly monitor the status indicator lights of the module and check for any signs of abnormal operation. Regularly clean the exterior of the equipment to prevent dust and debris from accumulating, especially in dusty industrial environments. Perform routine data integrity checks to ensure the accuracy and correctness of the collected and transmitted data. If any issues are detected, please refer to the detailed troubleshooting guide provided by the manufacturer. It is also recommended to keep the firmware of the module updated to benefit from the latest features, performance improvements, and security patches.

Vibro meter Other product models:

Vibration Monitor AMS3120-A3120/022-000

Vibro-meter VM600 MPC4 200-510-100-034

Vibro-meter 200-566-000-112

VIBRO-METER 200-566-000-112

Vibro-meter 200-582-500-021

VIBRO-METER VM600 RPS6U 200-582-500-013

Vibro-meter VM600 CPUM 200-595-100-014

Vibro-meter VM600 CPUM 200-595-100-014

VIBRO-METER SIM-275A 200-582-500-013

VIBRO-METER VM600 RPS6U 200-582-500-013

VIBRO-METER VM600 CPUM 200-595-100-014

Vibro-Meter VM600MPC4 200-510-017-017

VIBRO-METER MPC4 200-510-078-115

VIBRO-METER MPC4 200-510-077-313

VIBRO-METER RPS6U 200-582-200-021

VIBRO-METER XIO16T 620-002-000-113

Vibro-Meter GSI-127-A2-B2

Vibro-meter GSI127 244-127-000-017-A2-B02

VIBRO-METER VM600 IOCN 200-566-000-113

VIBRO-METER 244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0

VIBRO-METER 244-704-000-042-A2-B01-C100-D20-E0.5-F10000-C0-H0-I0

Vibro-Meter VM600 IOCN 200-566-000-113

VIBRO-METER IOC4T-200-560-000-1Hh

VIBRO METER VM600 MPC4 200-510-SSS-1Hh

Vibro-meter 200-510-071-113

Vibro-meter VM600 MPC4

VIBRO-METE IOC8T

VIBRO-METER CMC16 200-530-022-014

Vibro-meter SIM-330A 200-582-500-021

VIBRO-METER VM600 CPU M

VIBRO-METER VM600 MPC4 200-510-071-113

vibro-meter 244-704-000-042

VIBRO-METER SIM-275A 200-582-500-013

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626