Description

200-510-076-114 is a high-performance signal processing module designed to regulate and optimize electrical signals in industrial automation systems. It can filter out unwanted noise and interference, ensuring that only clean and accurate signals are transmitted to the connected devices. This module can be seamlessly integrated with existing control platforms and backplane systems, improving the overall signal integrity of the automation system. With its advanced signal processing algorithms, it can adapt to different signal types and frequencies, making it a universal choice for various applications.

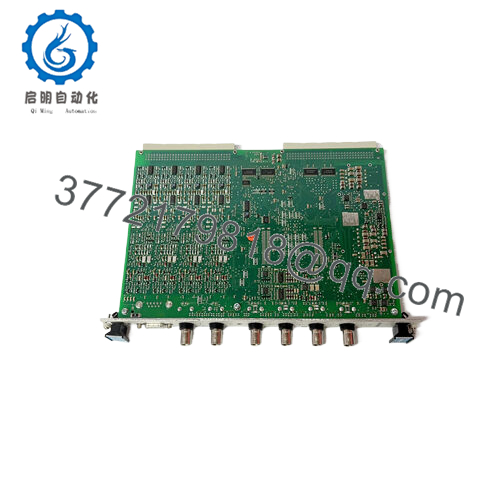

200-510-076-114

Technical specifications:

200-510-076-114

VIBRO-METER

Signal processing module

24 VDC ±15%

-25 ° C to 70 ° C DIN rail installation

110mm x 65mm x 35mm 300g

Analog, digital

CE、RoHS

7W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

200-510-076-114

Main features and advantages:

The advanced signal processing capability of200-510-076-114ensures consistency and accuracy in data transmission, reducing the possibility of errors caused by signal interference. This helps to improve process control, enhance product quality, and reduce production losses. Its sturdy design and wide operating temperature range also make it suitable for harsh industrial environments, reducing the need for frequent replacement.

200-510-076-114provides precise and reliable control over industrial processes, optimizing efficiency and productivity. Its enhanced processing capabilities allow for faster response times and more complex control strategies, enabling manufacturers to meet demanding production schedules. Compatibility with multiple protocols simplifies system integration, reducing the engineering time and cost required for deploying new devices or upgrading existing systems.

The predictive maintenance capability of VM600 has immeasurable value in preventing unexpected equipment failures. By detecting issues early on, it enables maintenance teams to schedule repairs at convenient times, avoiding costly downtime and unplanned downtime. This not only extends the service life of industrial equipment, but also reduces long-term maintenance costs. The detailed diagnostic information provided by VM600 also helps identify the root cause of problems and achieve continuous process improvement.

MPC4 simplifies communication in industrial automation networks, eliminates the need for multiple protocol converters, and reduces system complexity. Its reliable data transmission ensures seamless operation of connected devices and improves overall system performance. The ability to support multiple protocols makes automation systems forward-looking and easier to integrate emerging technologies. This has led to a more flexible and scalable automation infrastructure, enabling enterprises to adapt to constantly changing market demands.

200-510-076-114

Application areas:

In the automotive manufacturing industry,200-510-076-114ecan be used to adjust the signals of sensors on assembly lines to ensure accurate data collection for quality control. 200-510-111-034 controls the operation of robot welding and painting equipment, optimizing the production process to improve efficiency and accuracy. VM600 monitors the health status of large motors and gearboxes to prevent malfunctions and ensure continuous production. MPC4 enables communication between different equipment in the factory workshop, promoting the integration of new automation technologies and the implementation of Industry 4.0 plans.

In the chemical processing industry, 200-510-076-114e ensures the integrity of sensor signals for measuring temperature, pressure, and chemical composition, achieving precise process control. 200-510-111-034 regulates the flow of raw materials and controls the reaction process to ensure product quality and safety. VM600 monitors the condition of pumps, valves, and reactors to provide early warning of potential faults. MPC4 integrates different control systems and equipment, achieving seamless operation of the entire chemical plant and improving overall process efficiency.

In the field of power generation, 200-510-076-114e processes signals from sensors on turbines and generators, achieving accurate monitoring of power output and equipment performance. 200-510-111-034 controls the operation of power generation equipment to optimize energy production and grid stability. VM600 monitors transformers, switchgear, and other electrical equipment to ensure reliable power distribution. MPC4 enables communication between different components of the power grid, promotes the integration of renewable energy, and improves the overall efficiency of power generation and distribution systems.

200-510-076-114

Related products:

200-510-076-115: 200-510-076-114 has additional signal processing channels and enhanced noise reduction capabilities.

200-510-111-035:200-510-111-034 has faster processing speed and increased memory capacity.

VM610: VM600 has extended monitoring capabilities, including support for more sensor types and advanced analysis capabilities.

MPC5: The next generation multi protocol controller that supports emerging industrial protocols and enhanced network security features.

Installation and maintenance:

Before installing 200-510-076-114, 200-510-111-034, VM600, and MPC4, it is essential to thoroughly review the system requirements and ensure compatibility with existing equipment. For 200-510-076-114, check the input and output signal specifications to ensure proper connection with sensors and other devices. When installing 200-510-111-034, verify the power supply and communication interface, and carefully program the control algorithm according to the application requirements.

For VM600, choose the installation location that provides the best access to the monitored device location and ensure the correct calibration of the sensors before debugging. When installing MPC4, configure the communication protocol correctly to ensure seamless data exchange with other devices in the network. It is recommended to update the firmware of all devices to the latest version provided by the manufacturer to benefit from the latest features and security enhancements.

During ongoing maintenance, regularly check the status indicator lights of each device to monitor its operational status. Regularly clean the exterior of the equipment, especially in dusty or dirty environments, to prevent dust accumulation and overheating. For VM600, regular sensor calibration and data analysis are conducted to ensure accurate monitoring. Check the communication connections of all devices for signs of looseness or damage, and promptly replace any faulty components. By following these maintenance practices, the long-term reliability and optimal performance of these industrial automation products can be ensured.

Vibro meter Other product models:

Vibration Monitor AMS3120-A3120/022-000

Vibro-meter VM600 MPC4 200-510-100-034

Vibro-meter 200-566-000-112

VIBRO-METER 200-566-000-112

Vibro-meter 200-582-500-021

VIBRO-METER VM600 RPS6U 200-582-500-013

Vibro-meter VM600 CPUM 200-595-100-014

Vibro-meter VM600 CPUM 200-595-100-014

VIBRO-METER SIM-275A 200-582-500-013

VIBRO-METER VM600 RPS6U 200-582-500-013

VIBRO-METER VM600 CPUM 200-595-100-014

Vibro-Meter VM600MPC4 200-510-017-017

VIBRO-METER MPC4 200-510-078-115

VIBRO-METER MPC4 200-510-077-313

VIBRO-METER RPS6U 200-582-200-021

VIBRO-METER XIO16T 620-002-000-113

Vibro-Meter GSI-127-A2-B2

Vibro-meter GSI127 244-127-000-017-A2-B02

VIBRO-METER VM600 IOCN 200-566-000-113

VIBRO-METER 244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0

VIBRO-METER 244-704-000-042-A2-B01-C100-D20-E0.5-F10000-C0-H0-I0

Vibro-Meter VM600 IOCN 200-566-000-113

VIBRO-METER IOC4T-200-560-000-1Hh

VIBRO METER VM600 MPC4 200-510-SSS-1Hh

Vibro-meter 200-510-071-113

Vibro-meter VM600 MPC4

VIBRO-METE IOC8T

VIBRO-METER CMC16 200-530-022-014

Vibro-meter SIM-330A 200-582-500-021

VIBRO-METER VM600 CPU M

VIBRO-METER VM600 MPC4 200-510-071-113

vibro-meter 244-704-000-042

VIBRO-METER SIM-275A 200-582-500-013

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626