Description

What This Product Solves

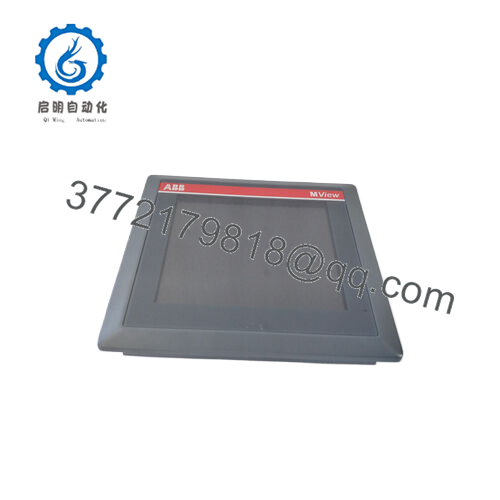

In industrial automation, clear and efficient operator interaction with control systems is crucial for flawless process management and rapid response to operational conditions. The ABB 1TGE120028R0010 is a Human Machine Interface (HMI) touch panel designed to meet this essential need. By providing operators a highly intuitive and responsive interface, this product solves key challenges related to process visibility, real-time data monitoring, and streamlined control actions. In settings where accurate interpretation of system status and quick intervention can determine the difference between smooth operation and costly downtime, the ABB 1TGE120028R0010 ensures that data from sensors, PLCs, and DCS platforms are displayed clearly and interactively. Its role becomes especially vital in industrial automation environments focused on process control, where seamless communication between humans and machines is a daily requirement for system stability and operational efficiency.

How the Product Works & Fits into a System

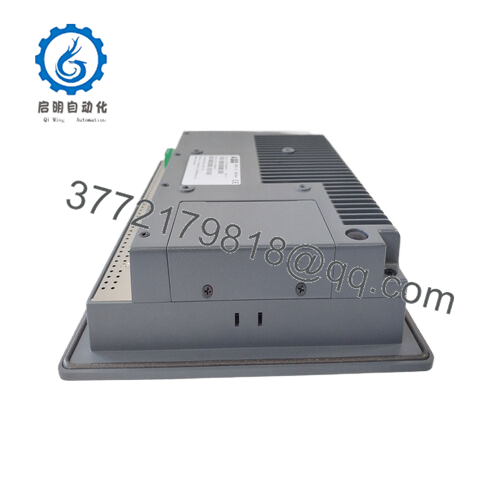

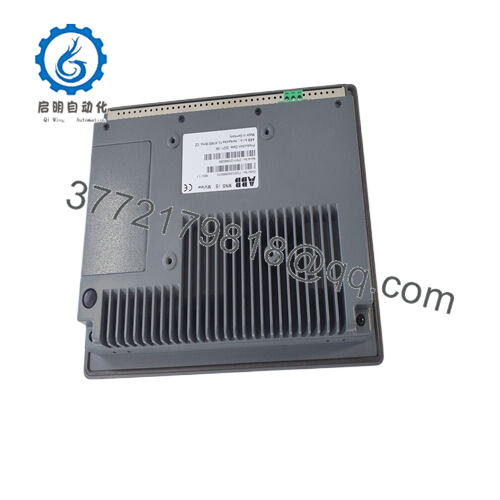

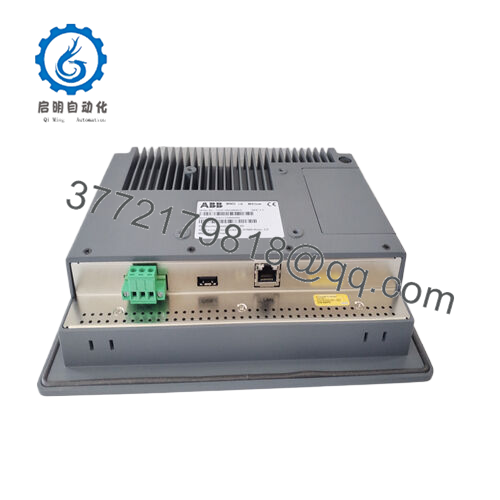

The ABB 1TGE120028R0010 functions as a modular communication interface within wider ABB industrial systems, specifically as a touch panel for Human Machine Interface applications. Positioned at the forefront of the automation control architecture, it facilitates operator interaction with control processes by providing visual feedback, alarm management, and real-time system updates via its 8.4-inch display. This HMI integrates seamlessly with ABB’s MView platform and communicates efficiently with controllers, PLCs, and SCADA systems using standard communication protocols to relay process status and accept commands. Its modular design allows it to be part of a scalable control system that supports upgrades and expansions without major redesign. Diagnostics and status LEDs aid in quick status identification, reinforcing reliability and ease of maintenance in complex automation setups.

Technical Highlights Summary

| Specification | Details |

|---|---|

| Model Number | ABB 1TGE120028R0010 |

| Brand | ABB |

| Type | Human Machine Interface (HMI) |

| Display Size | 8.4 inches |

| Weight | Approx. 4 kg |

| Dimensions | 220 mm x 210 mm x 120 mm |

| Interface/Bus | Ethernet, MLink Protocol |

| Operating Temp Range | -20°C to 60°C |

| Compliance | CE, UL |

| Typical Power Draw | Not specified |

Real-World Benefits

Selecting the ABB 1TGE120028R0010 provides users with a highly legible, user-friendly touch interface that enhances operator situational awareness and control precision. The responsive display ensures that operators can monitor multiple parameters simultaneously and make informed decisions quickly, which reduces reaction time to alarms or process changes. Engineered for durability, it withstands industrial environments, maintaining long-term performance even under conditions involving temperature fluctuations and electrical noise. Its integration with ABB’s broader control systems reduces engineering overhead by offering compatibility and ease of installation, making it a reliable component in a wide range of industrial automation projects. The ABB 1TGE120028R0010 ensures that control solutions not only function but empower operators for better process outcomes.

1TGE120028R0010

1TGE120028R0010

1TGE120028R0010

Typical Use Cases

The ABB 1TGE120028R0010 is widely deployed across industries such as manufacturing, power generation, and water treatment facilities. In manufacturing plants, it provides critical operator control points for assembly lines and automated machinery, ensuring smooth operations and quick interventions. Power generation plants rely on such HMIs to manage turbine controls and electrical distribution systems with precision. Water treatment plants benefit from its ability to display complex process data clearly, aiding in maintaining continuous treatment cycles and ensuring water quality standards. Its application in environments requiring consistent uptime and rapid data refresh cycles underscores its role in supporting critical system uptime and robust process control.

Compatible or Alternative Products

MView 1TGE120028R0001 – Earlier generation HMI panel with similar interface capabilities

1TNE970000R0100 – Compact HMI panel designed for space-constrained applications

3BSE023750R1 – Communication interface module for expanded network integration

3BSE058758R1 – High-resolution HMI panel for enhanced display quality

3BSE022786R1 – Touchscreen operator interface for flexible control solutions

1TMA170000R0100 – Accessory module for extended connectivity options

1TNE970000R0200 – Larger format HMI panel designed for advanced visualization needs

Setup Notes & Maintenance Insights

Before installation of the ABB 1TGE120028R0010, the physical mounting space must be verified to accommodate its 220 mm x 210 mm x 120 mm dimensions. Ensure the system’s communication network supports Ethernet or the MLink protocol for seamless integration. Firmware and software configurations should be updated to the latest version for optimal performance and security enhancements. Maintenance mainly involves routine cleaning of the touch display surface to maintain responsiveness and periodic verification of LED status indicators for operational health checks. Connector inspections and cable integrity checks should be part of regular service schedules to prevent communication disruptions. This module’s modular nature facilitates straightforward firmware updates and diagnostic tests that help keep the automation system running smoothly.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626