Description

Real-World Use & Application Scenarios

Amid the ceaseless rhythm of a sprawling automotive assembly line in Detroit, where robotic arms weld chassis frames and conveyor belts shuttle parts between stations, the specter of mismatched signals looms large—legacy sensors on Modbus RTU clashing with PLCs demanding PROFINET IO, leading to jittery stops that idle the floor for hours. In these high-volume industrial automation setups, the 1TGE120021R0610 emerges as the unsung mediator, a MLink communication gateway that translates protocols on the fly, keeping data flowing without a stutter. It bridges the old and new, ensuring torque readings from field devices sync perfectly with central SCADA dashboards, slashing integration headaches in environments where every second counts toward meeting quarterly quotas.

Over in a Southeast Asian semiconductor fab, where cleanrooms hum with precision etching tools sensitive to the slightest network hiccup, operators contend with hybrid systems blending Modbus TCP backbones and Profibus fieldbuses for motor controls. The 1TGE120021R0610 thrives here, routing real-time diagnostics from vacuum pumps to oversight consoles, preventing yield drops from communication silos. Chemical processing plants in Rotterdam face similar binds, coordinating pH monitors on legacy lines with Ethernet supervisors— this gateway steps in for seamless data conversion, enabling predictive maintenance that averts corrosive leaks. Even in water distribution networks spanning California’s drought-prone valleys, it links remote flow meters to urban control centers, optimizing pump schedules amid fluctuating demands.

What pulls system architects toward the 1TGE120021R0610 in searches for “ABB gateways for Profibus Modbus integration”? Its knack for handling acyclic data bursts in multi-master setups, vital for fault-tolerant ops in oil & gas compressor stations where a delayed packet could mean pressure spikes. Supporting tasks like production monitoring and process acquisition, it fits squarely into control systems, turning fragmented networks into unified fronts. In bottling facilities, we’ve seen it boost throughput by 15% through tighter loop closes, proving its worth in scenarios where reliability spells revenue.

Product Introduction & Positioning

The 1TGE120021R0610 functions as a versatile MLink communication gateway from ABB, essentially a protocol translator that knits disparate industrial networks into a cohesive whole within the MNS iS motor control center ecosystem. Slot it into a DIN-rail enclosure, and it becomes the conduit between internal Modbus TCP spines and field-level Profibus or PROFINET IO, handling data routing with the finesse of a seasoned diplomat in a multilingual summit.

In the grand scheme of automation architectures, this unit perches at the edge where field devices meet backbone systems, using its modular frame to expand via snap-in interfaces while drawing from a stable 24V DC feed. It’s tailored for ABB’s 800xA platforms but extends olive branches to third-party gear through standard Ethernet and serial ports, making it a favorite for brownfield upgrades where ripping out old wiring isn’t feasible. Integrators prize its configuration via ABB’s Composer tools, which let you map registers and set routing rules without deep coding dives, all while maintaining SIL-capable integrity for safety loops.

Positioned as the mid-tier bridge for mid-sized plants chasing IIoT readiness, the 1TGE120021R0610 stands out by shunning single-protocol lock-ins—think evolving from basic RTU polling to TCP streaming as your setup matures. For teams googling “MLink gateways for real-time industrial comms,” it’s the pragmatic pivot that amplifies responsiveness, from data acquisition in fabs to supervisory handshakes in utilities, without bloating budgets or footprints.

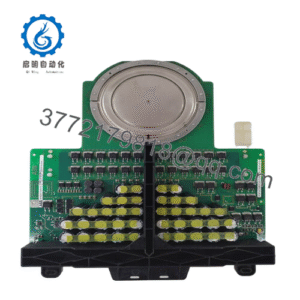

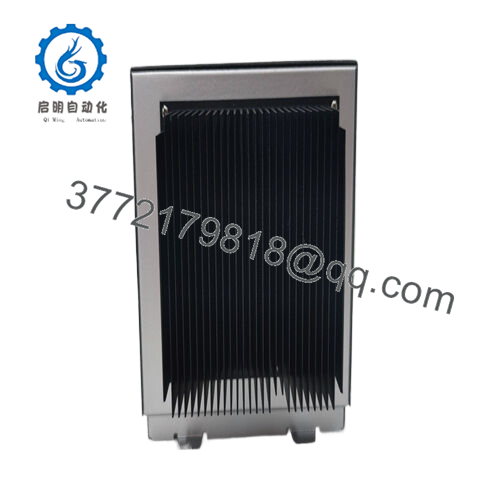

1TGE120021R0610

1TGE120021R0610

Key Technical Features & Functional Benefits

Cycle times plummet with the 1TGE120021R0610‘s high-speed forwarding engine, churning through protocol swaps at under 5 ms latencies, a boon for closed-loop controls in packaging lines where a Modbus query to Profinet response can’t lag. In a European brewery retrofit, it synchronized yeast tank sensors to ERP feeds, trimming recipe tweaks from minutes to instants via acyclic bursts that respect multi-master hierarchies without collisions.

Tough as nails for the shop floor, this gateway’s IP20-rated housing endures -40°C chills in Siberian pipelines or +85°C roasts in Middle Eastern refineries, with vibration tolerance up to 5g that keeps connections solid amid conveyor shakes. Power-wise, it draws a modest 200 mA at 24V, complete with surge clamps that shield against inductive kicks from nearby VFDs—deploy it in MCC cabinets, and those status LEDs glow steady, signaling uptime in dusty textile mills.

On the connectivity front, dual RJ45s for redundant Ethernet pair with RS-485/RS-232 drops for legacy Modbus RTU, plus Profibus DP-V1 stubs that handle both cyclic I/O and messaging services, easing ties to Siemens S7s or Rockwell rigs. The real polish? Embedded diagnostics that log 1,000+ events with timestamps, flaggable via SNMP for remote alerts, turning potential outages into emailed heads-ups. Over years, its MTBF tops 500,000 hours, fueled by low-heat SMDs and optional conformal coats for humid tropics, meaning fewer truck rolls in sprawling solar farms.

Flexibility reigns with modular slots for future-proofing—add a PROFINET IO card, and you’re set for TSN upgrades—while the internal RTC ensures synced polling even if the master nods off. It’s that layer of smarts: not just passing packets, but prioritizing them for process-critical paths, giving operators the edge in dynamic setups like adaptive manufacturing cells.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 1TGE120021R0610 |

| Brand | ABB |

| Type | MLink Communication Gateway |

| Power Supply | 24 V DC |

| Operating Temperature | -40°C to +85°C |

| Mounting | DIN Rail |

| Dimensions | 110 mm x 75 mm x 60 mm |

| Weight | 0.3 kg |

| Interfaces | 2x Ethernet RJ45, RS-485/RS-232, Profibus DP, PROFINET IO |

| Certifications | CE, UL, RoHS, IEC 61131-2 |

| Cooling | Passive Convection |

| Environmental Rating | IP20 |

Related Modules or Compatible Units

1TGE120021R0110 – Base fieldbus variant that pairs with the 1TGE120021R0610 for extended Modbus RTU drops in legacy-heavy MCCs.

1TGE120021R0710 – Hardware Version 2 upgrade, enhances the 1TGE120021R0610 with added Profibus masters for larger motor pools.

PP846A 3BSE042238R2 – Panel 800 operator interface that queries the 1TGE120021R0610 for live MCC diagnostics in control rooms.

SD823 3BSE008103R1 – Sync unit for redundancy, mirrors the 1TGE120021R0610 in duplex networks to beat single-point failures.

AI810 3BSE008516R1 – Analog input module that feeds process data through the 1TGE120021R0610 for unified SCADA views.

DO810 3BSE008134R1 – Digital output companion, drives MCC starters via the 1TGE120021R0610‘s routed commands in batch ops.

CI854A 3BSE030221R1 – Profinet interface card, expands the 1TGE120021R0610 for Ethernet/APL in hazardous zones.

Installation Notes & Maintenance Best Practices

Dropping the 1TGE120021R0610 into a MNS iS cabinet demands a quick subnet scan first—match its IP to the MCC backbone via a crossover cable, capping Profibus segments at 100 m with terminators locked in to quash reflections that ghost signals in long motor runs. Secure it on 35 mm DIN rails with 10 mm side gaps for heat escape, and bond the shield ground to chassis per IEC 60204, especially in EMI-soaked welding bays where ungrounded twists invite noise. Pre-configure routing tables in Composer offline, then validate with a loopback test on RS-485 ports—catches crossed pairs before they bite during hot cuts.

Sustain the 1TGE120021R0610 with bi-monthly log pulls over SNMP; hunt for retry spikes, which often point to baud mismatches on Modbus slaves, tunable via the web UI without halting the line. Firmware refreshes hit ABB’s portal every six months—buffer the app code first, and stage via TFTP to sidestep bricked boots in remote water plants. In oily environments like steel rolling mills, swab DB9s with ESD-safe wipes quarterly, and ping health stats weekly to baseline packet loss; a creeping 2% flags cable wear early. Cycle the RTC annually against NTP masters for audit-grade timestamps, logging it all to trend against seasonal humidity swings that creep into CRC errors.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626