Description

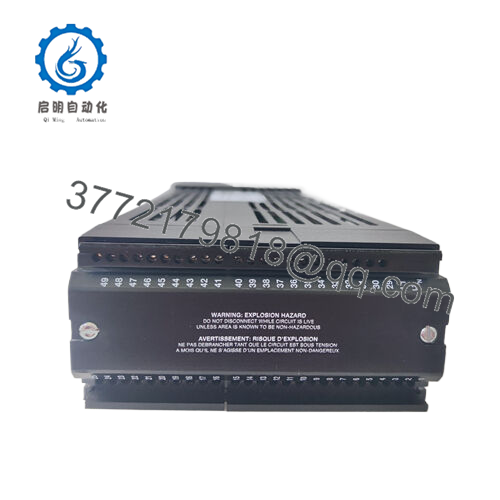

1800RZ21100A Product Introduction:

The 1800RZ21100A is a highly versatile I/O module that integrates effortlessly into existing automation architectures. It is designed to interface with popular control platforms, leveraging the backplane system to communicate efficiently with other modules within the system. With support for industry-standard protocols like Modbus TCP and Profibus, it can connect with a diverse range of devices, from sensors that detect temperature, pressure, and flow to actuators that control machinery and valves. This enables the creation of a unified and responsive control network.

This module comes equipped with built-in diagnostic capabilities, allowing engineers to quickly identify and rectify any issues. It constantly monitors its own performance and provides real-time status updates that can be accessed remotely, facilitating proactive maintenance. Redundancy features are also incorporated, ensuring that in the event of a component failure, the system can continue to operate without significant disruption. Positioned at the core of the I/O architecture, the 1800RZ21100A acts as a reliable intermediary, accurately translating sensor inputs into actionable commands for the control system and sending output signals with precision. Its modular design makes it easy to add or remove from the system, adapting to changing production requirements or system expansions.

Technical specifications:

Model Number:1800RZ21100A

Brand:ABB

Type:I/O Module

Supported Protocols:Modbus TCP, Profibus

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

Main features and advantages:

Opting for the 1800RZ21100A I/O module offers a plethora of tangible benefits for industrial operations. Engineered with a focus on high reliability, it significantly minimizes unplanned downtime, which is a critical factor in industries where every minute of production loss can translate into substantial financial losses. Its advanced signal processing capabilities guarantee consistent performance, reducing output variability that could otherwise impact product quality.

Maintenance efficiency is another area where this module excels. The built-in diagnostics not only speed up issue detection but also simplify the troubleshooting process, reducing the time engineers spend on manual inspections. This, in turn, leads to lower maintenance costs and reduced engineering overhead. Integration is a breeze, thanks to its broad protocol support and modular design, enabling faster deployment of new automation projects or upgrades to existing systems. By investing in the 1800RZ21100A, companies can expect smoother operations, enhanced productivity, and a lower total cost of ownership over the module’s lifespan.

Before installing the 1800RZ21100A I/O module, it is crucial to verify bus compatibility with your existing control system. Ensure that the interface/bus type matches and that the system’s firmware is up to date to prevent any communication issues. Additionally, allocate sufficient cooling space around the module, as proper ventilation is essential for maintaining optimal operating temperatures, especially in high-temperature industrial environments.

For ongoing maintenance, regularly check the LED status indicators on the module. These lights provide quick visual cues about the module’s operational status, including power availability, communication activity, and error detection. Periodically inspect the connectors for any signs of wear or damage, as loose or corroded connections can lead to signal degradation. A yearly functional test is also recommended to confirm that the module continues to perform within specified parameters, ensuring its long-term reliability.

Other models of ABB series:

RED670 1MRK002246-BC

RED670 1MRK002810-AC

RED670 LCD screen

REF 543

REF541

REF541DB115BAAA

REF541KM115AAAA

REF541REF541KM118AAAA

REF615 HBFFAEAGNEA1ANA11G

REF615 HBFDACAFNEA1ANN11G

REF615 HBFCABABC1ANN11G

REF615 HBFDACADABC1ANN2XG

REF615A_1G

REF615C_D

REF615E_1G HBFCACABAAC1ANN11G

REF615E_1G HBFEAEAGNEA1ANA11G

REF615E_D

REF615E_E HBFFAEAGABC1BNA2XE

REF615E_G HBFHAEAGANB1BAN1XG

REF615E_G HBFHAEAGANB1BAN1XG

REF615 English version

REF620

REF620E-1GNBFNAANNNDA1BNNN11G

REG216EA62

REG216Vc62a

REG670 1MRK002826-AC

REJ601 BD446NN1XG

REJ603B2NN1NB44NNJ

REL316

REL511 1MRK003492-AL

REM 545

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626