Description

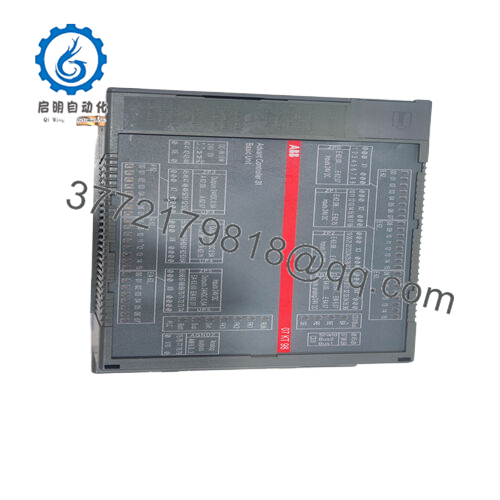

ABB 07KT98C GJR5253100R028 Product Introduction:

ABB 07KT98C GJR5253100R028 is a central processing unit that serves as the core of the Advant Controller 31 system. It acts as the ‘brain’ of industrial automation settings, receiving large amounts of data from sensors, analyzers, and other input devices. These data can include analog signals from temperature sensors, pressure gauges, and flow meters, as well as digital signals from switches and relays.

After receiving the data, 07KT98C GJR5253100R028 will use its high-speed processor to process it. Its clock speed is 100 MHz, capable of executing complex control algorithms in a very short amount of time. This unit has 2 MB of program memory and 1 MB of data memory, capable of storing and running large control programs, and processing large amounts of real-time data.

After processing, the unit will send control signals to actuators such as motors, valves, and pumps, adjusting their operation based on input data and programmed control logic. It interfaces with other components in the system through multiple communication ports. Ethernet ports can achieve high-speed data transmission, making it easy to connect to the entire plant network or integrate with higher-level control systems. In addition, it also has RS-232 and RS-485 ports, which can be used to connect traditional devices or devices that require serial communication.

07KT98C GJR5253100R028 also supports a wide range of analog and digital input/output (I/O) functions. It has 8 analog input channels and can handle various signal types, including 0-5V, -5-+5V, 0-10V, -10-+10V, 0-20mA, 4-20mA, and PT100 (2-wire or 3-wire) temperature sensors. These analog inputs can also be used as digital inputs when needed. In terms of output, it has 4 analog output channels that can generate signals within the range of -10-+10V and 0-20mA. The flexibility of this I/O function makes it suitable for various industrial applications.

Technical specifications:

Model 07KT98C GJR5253100R028

Brand ABB

Type Central Processing Unit (CPU)

Input voltage 24V DC

Operating temperature range: -40 ° C to 70 ° C; Storage: -40 ° C to 85 ° C

The installation method is designed to facilitate integration into industrial control panels

Size [If there is an accurate size, please provide]

Weight [If there is a specific weight, please indicate]

Interface/Bus Ethernet RS – 232、RS – 485

Certification CE, UL (assuming compliance with these standards)

Supports Ethernet based protocols for high-speed communication and standard serial communication protocols for traditional devices

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

Main features and advantages:

ABB 07KT98C GJR5253100R028 is designed for long-term reliability and high-performance operation. Its sturdy structure enables it to withstand harsh industrial environments, including extreme temperatures, high humidity, and electrical interference. This means it can be deployed in challenging locations such as mines, refineries, and outdoor substations without affecting its performance.

The high-speed processing capability of this unit enables it to process real-time data with extremely high accuracy and speed. This is crucial for applications that require instant decision-making, such as high-speed manufacturing processes or power grid control systems. By processing data quickly and accurately, it helps optimize industrial processes, thereby improving production efficiency, reducing waste, and lowering energy consumption.

07KT98C GJR5253100R028 also simplifies system integration. It is compatible with a wide range of communication protocols and I/O devices, which means it can be easily integrated into existing industrial automation systems. This reduces the engineering costs associated with upgrading or expanding control systems. Whether you want to add new sensors, actuators, or other components to the system, 07KT98C GJR5253100R028 can be successfully integrated.

In terms of maintenance, the built-in diagnostic and self-monitoring functions of the unit enable easy detection and troubleshooting. It can continuously monitor its own performance and quickly alert the operator when any signs of malfunction appear. This proactive maintenance approach helps minimize unplanned downtime and extend the lifespan of the unit.

Application areas:

ABB 07KT98C GJR5253100R028 is widely used in multiple industries. In manufacturing, it is used for machine control systems. For example, in a textile factory, it can control the speed, tension, and pattern settings of the loom to ensure high-quality fabric production. In food and beverage factories, it can monitor and control the bottling line processes such as filling, capping, and labeling to maintain product quality and production efficiency.

In the field of energy, it plays an important role in power generation and distribution. In thermal power plants, it can control the operation of boilers, turbines, and generators to ensure stable power output. In a wind farm, it can adjust the pitch angle and yaw angle of wind turbines based on wind speed and direction data to maximize energy capture. It is also used in smart grid systems to manage power flow, balance supply and demand, and improve grid reliability.

The chemical industry has also benefited greatly from 07KT98C GJR5253100R028. It can be used to control chemical reactions in reactors, monitor the flow of raw materials, and ensure the safe and efficient operation of chemical processes. In petrochemical plants, it can regulate the temperature and pressure of the distillation tower, prevent dangerous situations from occurring, and ensure consistency in product quality.

Related products:

ABB 07KT98C GJR5253100R3260: This is a variant of the 07KT98C series designed specifically for applications that require enhanced Ethernet communication capabilities. It may provide different data transmission rates or additional network related features.

ABB AC500 PLC Platform: This is a more advanced and comprehensive programmable logic controller platform. It provides higher levels of processing power, a wider range of I/O options, and enhanced software development capabilities. It is suitable for large and complex industrial automation projects, in which 07KT98C GJR5253100R028 may not meet scalability requirements.

ABB 07KT97 GJR5253000R4270: This is an older product from ABB. Although it may have similar basic functionality to 07KT98C GJR5253100R028, it may lack some advanced features and performance improvements of the new model. However, for traditional system upgrades, if the existing infrastructure is more compatible with the old unit, it can be a cost-effective option.

Installation and maintenance suggestions:

Before installing ABB 07KT98C GJR5253100R028, it is necessary to ensure that the power supply in the target system can provide a stable 24V DC voltage. Any fluctuation in the power supply may affect the performance of the unit and even lead to damage. In addition, check the communication interface to ensure compatibility with other system devices. Verify that the Ethernet, RS-232, and RS-485 ports are configured correctly and that the cables are in good condition.

In terms of physical installation, ensure that the installation location has sufficient space and is away from excessive vibration or heat sources. The unit should be installed in a well ventilated area to prevent overheating. Meanwhile, it is essential to strictly follow the installation guidelines provided by ABB, as improper installation may lead to connection issues and unreliable operation.

For ongoing maintenance, regularly inspect the unit for any physical signs of damage, such as cracks, loose connections, or signs of overheating. Monitor the operating temperature of the monitoring unit, as temperatures outside the specified range may cause performance degradation. Use the built-in diagnostic tool to check for any error messages or abnormal behavior. Regularly backup the programs and data stored in the unit to prevent data loss in the event of hardware failure.

Other ABB product models:

ABB Ds200TCQAG1B

ABB DSAI130

ABB DSAI130A 3BSE018292R1

ABB DSAI130D 3BSE003127R1

ABB DSAI155A 3BSE014162R1

ABB DSAO120

ABB DSAO120A 3BSE018293R1

ABB DSDO115A

ABB DSDP140B

ABB DSDP140B 57160001-PU

ABB G2000A5.7ST

ABB GCC960C102 3BHE033067R0102

ABB GDB021BE HIEE410455P104

ABB GDB021BE01 HIEE300766R0001

ABB GDC801B 3BHE051592R0101

ABB GDC801B102 3BHE051592R0102

ABB GFD233A 3BHE022294R0101

ABB GJR5253100R0270 07KT98

ABB GLBS200516R

ABB GMKP2800-32IBY

ABB GNT0104500R0002

ABB GRBTU 3BSE013175R1

ABB GVC750BE101 3BHE009681R0101 GVC750BE101 3BHE013088R001 5SHY3545L0010

ABB HAI805

ABB HBFFAEAGNBA1BAA11G

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626