Description

What This Product Solves

In the high-vacuum precision of semiconductor etching and deposition processes, delivering stable, high-current DC power to RF generators and electrode stacks is non-negotiable—yet in Applied Materials (AMAT) platforms like the Centura or Producer series, power fluctuations from grid harmonics or load transients can destabilize plasma sheaths, causing etch nonuniformity or film defects that scrap 300mm wafers and derail yield targets in fabs targeting 2nm nodes. These vulnerabilities escalate during chamber conditioning or recipe transitions, where a voltage sag delays ignition, forcing extended ramps that inflate cycle times and expose tools to arcing risks, compounding the challenges of 24/7 operations under SEMI E10 uptime standards and escalating energy costs in cleanroom environments.

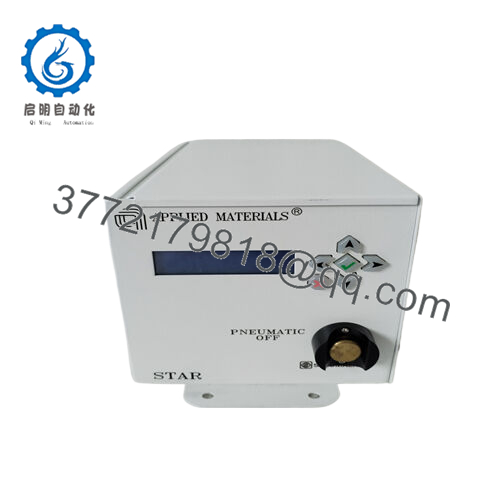

The Applied Materials 0190-15779 tackles this as a DC Power Supply Module, optimized to furnish programmable, low-ripple DC outputs for AMAT’s plasma processing tools, ensuring consistent plasma density without the overshoots that plague off-the-shelf supplies. It’s a vital upgrade in retrofits for Endura PVD clusters or Ultima HDP-CVD systems, where modular integration demands hot-swappable PSUs that interface seamlessly with VME controllers without process interrupts. For engineers addressing high-reliability industrial automation in wafer fab, this module intervenes when legacy supplies falter under 40kW draws or EMI bursts from 13.56 MHz sources, providing the current regulation that upholds I/O signal integrity in match networks and bias electrodes.

Imagine a metal etch step where the PSU must sustain 200V/200A arcs without ripple-induced microtrenching, or a dielectric deposition where precise current steps sync with gas flows to avoid pinholes—the Applied Materials 0190-15779 delivers, with its PMBus programmability and thermal safeguards that lock in stability amid thermal cycling. In these semiconductor process control hotbeds, it reduces the troubleshooting toll of waveform anomalies, piping telemetry to the tool HMI for proactive derates. Fundamentally, this power module reframes DC delivery as a plasma pillar, not a potential pitfall—bolstering the uniformity and throughput that safeguard yields, while facilitating scalable power architectures in your fab’s evolution toward EUV and beyond.

- 0190-15779

How the Product Works & Fits into a System

The Applied Materials 0190-15779 serves as a switch-mode DC powerhouse in AMAT tool ecosystems, converting 480VAC 3-phase inputs to programmable 0-200VDC outputs at up to 200A via IGBT-based rectification and resonant conversion—yielding <1% ripple with active PFC to comply with IEEE 519 harmonics, while modulating current via PMBus commands for ramp rates down to 1ms steps, all drawing from a chassis-mounted enclosure that vents 500 CFM to cap case temps at 50°C. It self-monitors via internal shunts and thermocouples, throttling on overcurrent or fan faults, and interfaces with the Synergy controller over RS485 for recipe-synced profiling.

Nestled in the power distribution layer of your tool stack, it mounts via rack ears in the electrical subframe, feeding isolated outputs to RF generators and pedestal electrodes while sourcing from facility UPS—suited for N+1 redundancy where paralleled units share loads and failover on sense lines, keeping plasma alive during swaps without recipe aborts. Protocol integration leverages PMBus 1.2 for voltage/current telemetry, with Modbus wrappers for fab SCADA, tunable through AMAT’s service console to match process windows like high-rate sputters.

Diagnostics are front-and-center: LCD readout for output stats and fault codes, plus dry contacts for interlocks that halt on undervoltage, streaming logs to the tool historian for arc forensics—no external meters needed. In a full architecture, it flanks AC conditioners upstream and match units downstream, crafting a fortified feed for closed-loop deposition—like in HDP-CVD where it ramps bias to 500W without overshoot, syncing with gas manifolds for void-free fills. For a Producer GT retrofit, the Applied Materials 0190-15779 would energize the showerhead, compensating for cable inductance to sustain uniform glow discharges. This native nesting trims qualification loops, positioning it as the steadfast surge in your plasma pipeline, fusing grid grit with the grace of gated precision for attuned, arc-averse execution.

| Specification | Details |

|---|---|

| Model Number | 0190-15779 |

| Brand | Applied Materials |

| Type | Programmable DC Power Supply Module |

| Input Voltage | 480 VAC 3-Phase |

| Operating Temp Range | 0°C to 50°C |

| Mounting Style | 19″ Rack / Chassis Mount |

| Dimensions | 19 x 7 x 16 in (483 x 178 x 406 mm) |

| Weight | 45 lb (20.4 kg) |

| Interface/Bus | PMBus / RS485 |

| Compliance | CE, UL, SEMI S2/S8, RoHS |

| Supported Protocols | PMBus 1.2, Modbus |

| Typical Power Draw | 40 kW max output |

Real-World Benefits

Embracing the Applied Materials 0190-15779 equips your AMAT tools with a supply sculpted for the fiery flux of plasma processing, where its resonant topology and PMBus agility clamp voltage transients to <0.5%—translating to etch depths varying <1nm across wafers, empowering tighter CD control that lifts yields by 2-3% in logic gates without the etch bias drifts that demand over-polish. This poise isn’t peripheral; it permeates recipes, enabling aggressive ramps that compress chamber turns from 45 to 35 minutes, distilling energy hogs into efficient etches across lot marathons.

Process engineers prize its sentinel suite, as shunt telemetry and fault latching spotlight arc precursors in the HMI queue—conceive a run lead preempting a match trip from current creep, tweaking via command sans cooldown. The rack-ready form eases integration rigors, with bolt-circle swaps that align with Endura frames without fab mods, hastening tool teardowns in uptime-obsessed lines where minutes monetize. Over fab spans pushing 5 years, it anchors performance constancy with a MTBF over 50,000 hours, its IP54 enclosure rebuffing HF vapors in etch bays, so your power pulses persist without the pit of periodic recalibrations.

Wider, the Applied Materials 0190-15779 greases extensibility by exposing analog trims for hybrid recipes, layering in endpoint signals where stable DC fuels spectroscopic models—easing the leap to selective etches without supply silos. These symbiotic savings recast power provisioning from a plasma peril to a plasma propellant, paring total tool tabulations while heightening the uniformity that heralds your semiconductor supremacy.

Typical Use Cases

The Applied Materials 0190-15779 roots in reactive ion etchers like the Centura 5200, rack-mounted in electrical bays to juice RF sources for contact hole cleans, where its 200A surge weathers ignition spikes amid Cl2 plasmas—core to process control environments sculpting vias below 10nm, shoring critical system uptime through recipe swaps or vent cycles in 5nm DRAM fabs. In these halogen-hazed hives, its regulation upholds high reliability, provisioning current fidelity that averts grassing and sidewall bows.

ALD reactors harness it for high-k precursors, energizing pedestal biases under 400°C pulses and ALD cycles, sustaining continuous uptime where fast data cycles from QCM sensors dictate cycle counts for EOT shrinks. Harsh precursor mists and thermal swings assay its vents, yet it proffers unswerving rails for conformal coats.

In sputter deposition clusters, the Applied Materials 0190-15779 drives Endura targets, modulating Ar flows with DC pulses over 40kW bursts—pivotal for used in Cu barrier seeds where power purity forestalls hillocks and electromigration fails. Across RIE, atomic layer deposition, and physical vapor deposition sectors, this module vitalizes applications hankering for robust DC in discharge domains, alchemizing volt surges into vaults of voidless victory.

0190-15780 – Higher-current variant (250A) for high-rate PVD in large-area tools.

0190-11595 – Legacy DC supply for ENI Optima integration in older Centura frames.

0300-76027 – Power distribution sub-assembly for multi-PSU redundancy.

0010-30137 – RF interlock companion for plasma-synced power gating.

0090-76133 – Synergy SBC tie-in for PMBus command orchestration.

0100-09145 – Video interconnect add-on for process monitoring with power logs.

A404KM-RT – Alternative RT module for real-time power profiling.

Before racking the Applied Materials 0190-15779 into your AMAT subframe, harmonize its PMBus address with the Synergy controller via the console—ID clashes can mute telemetry, stranding your ramps in manual mode. Probe the AC lugs for carbon tracking or loose strands from transit; a torque wrench at 10 Nm and insulation test >1MΩ nix phase imbalances that breed harmonics. Ventilation is vital—affix the filter grille and clock 400 CFM blowers in hooded bays, especially near RF decks hitting 45°C—simulate your kW profile to confirm. Pre-bias the outputs with a dummy load at 100A, nailing <0.2% regulation sans overshoot, and bond the chassis ground uniquely to bleed ESD from wafer boats.

In the fab, tending tilts toward telemetry over tinkering. Biweekly HMI sweeps for ripple readouts—<1% variance on 200V spells solidity, but spikes summon a harmonic analyzer for grid ghosts. Quarterly panel pops with grounded gloves and solvent swipes on bus bars banish arc char from humid purges; reclutch at spec to defy vibe vectors from pumps. Annually, assault with stepped loads via the sequencer to certify 99.9% holdup across fault sims, logging for lifecycle lulls. If droops dawn, tap AMAT’s remote PMBus sniffer over secure LAN, but these cadences keep the Applied Materials 0190-15779 as a discharge dynamo, funneling focus to forecasts over fixes.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626