Description

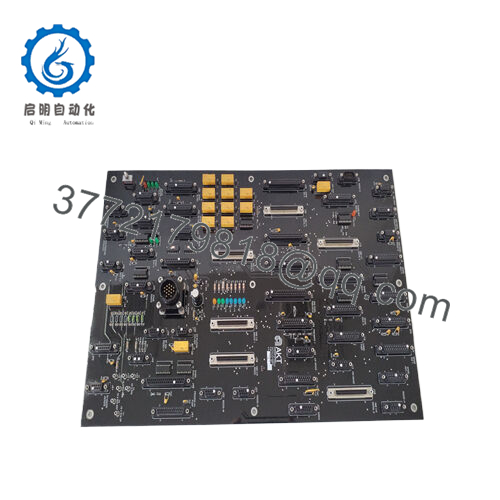

The 0100-71443 is a module associated with Applied Materials semiconductor equipment, typically found in advanced manufacturing environments. Although detailed public specifications are limited, it is most likely part of the control or process management system within Applied Materials’ suite of wafer processing tools. Applied Materials modules like the 0100-71443 are designed to enable precise control and automation of semiconductor fabrication steps including deposition, etching, or inspection processes. This module fits into a modular control system architecture, working alongside other specialized boards and modules to deliver fine control over chemical or physical processing conditions essential for high-yield semiconductor production.

The 0100-71443 module is integrated into semiconductor manufacturing systems used in markets such as IoT, communications, automotive, power electronics, and sensors. It supports automated handling and processing in vacuum cluster platforms or batch ALD (Atomic Layer Deposition) systems. By enabling efficient and repeatable wafer batch processing, this module helps manufacturers meet stringent process quality and throughput targets. Applied Materials emphasizes modularity and ease of maintenance, ensuring that parts like the 0100-71443 are compatible with broader tool configurations and can be rapidly serviced or replaced to minimize downtime.

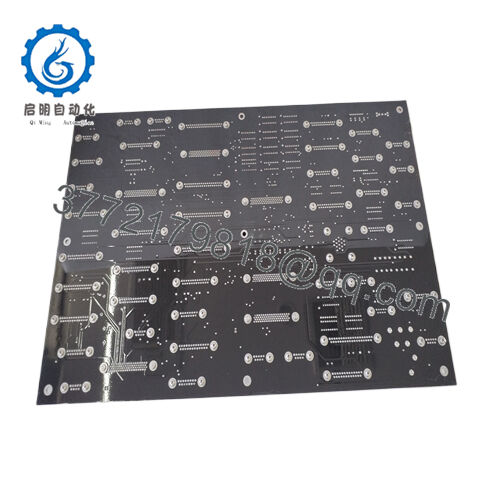

While exact dimensions and electrical data for the 0100-71443 are not explicitly available, it is designed to operate within the environmental and electrical standards typical of semiconductor fab cleanroom equipment modules—robust against contamination, temperature variations, and electrical noise. This ensures long-term stability and reliability crucial in high-volume manufacturing operations.

For installation, the 0100-71443 must be situated in the corresponding Applied Materials tool rack or cabinet, with attention paid to appropriate electrical connections, grounding, and environmental conditions. Maintenance best practices include regular system diagnostics to verify module functionality, preventive cleaning within controlled environments, and firmware updates when applicable to align with tool performance upgrades.

The module fits into various semiconductor fabs producing MEMS, sensors, power electronics, and communication components by driving critical process controls in the cluster or ALD systems. It is engineered to withstand cleanroom requirements, vibration, and electrical noise conditions commonly encountered in high-volume manufacturing environments.

- 0100-71443

For installation, the 0100-71443 requires compatible Applied Materials tool racks or cabinets with proper electrical connections and grounding. Maintenance includes routine diagnostics, cleaning in controlled environments, and firmware updates to sustain performance.

Standard warranty and global support come from Applied Materials, with documentation, spare parts availability, and remote diagnostics helping maintain uptime and equipment reliability within semiconductor fabs.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626