Description

What This Product Solves

In the intricate, high-volume world of semiconductor manufacturing and industrial process control, distributing precise gas mixtures and precursor flows to CVD chambers demands unerring control over valves, mass flow controllers, and pressure regulators—yet in Applied Materials (AMAT) AKT 55K platforms, legacy distribution boards often succumb to thermal drift or signal crosstalk from humid precursor lines, leading to uneven deposition thicknesses or void defects that compromise transistor performance and scrap entire lots in fabs pushing for 5nm yields. These inconsistencies surge during recipe changes or multi-wafer runs, where a lagged valve command can skew stoichiometry, forcing extended quals that balloon cycle times and expose tools to corrosive buildup, heightening the stakes in cleanrooms governed by SEMI F5 purity standards and relentless throughput pressures.

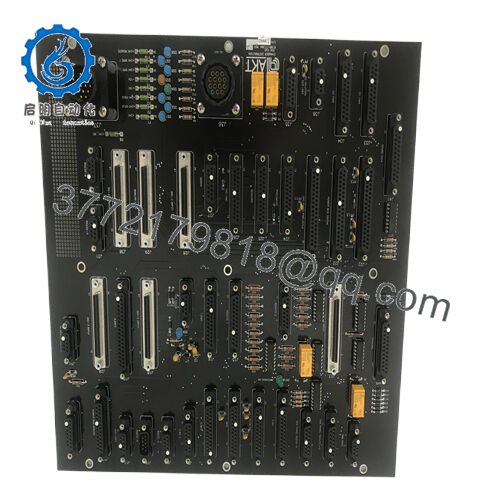

The Applied Materials 0100-71304 counters this as a Chamber Distribution Board for the AKT 55K CVD system, engineered to orchestrate real-time flow sequencing and feedback integration for uniform vapor delivery, ensuring consistent film quality without the fluctuations that undermine process windows. It’s a cornerstone in upgrades for AKT PECVD or LPCVD modules, where modular integration calls for drop-in boards that tie into Synergy controllers without manifold reconfigs. For engineers tackling high-reliability challenges in industrial automation for thin-film deposition, this board steps in when generic PLC interfaces can’t handle the analog precision of MFC loops or the digital handshakes for purge cycles, providing the signal conditioning that preserves I/O integrity amid 200°C line temps and trace moisture.

Picture a silicon nitride deposition where the board must ramp NF3 flows in 10sccm steps while polling backpressure to avert particle nucleation, or a TEOS oxide layer where valve hysteresis risks pinholes—the Applied Materials 0100-71304 prevails, with its embedded ADCs and relay drivers that lock in responses without jitter. In these semiconductor process control forges, it minimizes the engineering slog of custom calibrations, feeding diagnostics to the HMI for drift alerts. Ultimately, this distribution board transforms gas handling from a variability vortex to a velocity vector—cultivating the uniformity and efficiency that bolsters yields, while easing the roadmap to scalable deposition in your fab’s relentless pursuit of atomic-scale mastery.

- 0100-71304

How the Product Works & Fits into a System

The Applied Materials 0100-71304 acts as the flow maestro in AKT 55K CVD architectures, interfacing 16 analog channels from MFCs and transducers via 12-bit DACs/ADCs to modulate valve actuators and sample pressures up to 100 Torr—executing PID loops at 100 Hz for setpoint tracking, while driving digital outputs for solenoid purges and interlocks over RS485 links, all sourced from a 24VDC rail with onboard regulators that buffer against line noise for <0.5% flow repeatability. It processes Synergy commands to sequence multi-gas recipes, compensating for thermal expansion in lines with lookup tables, and flags excursions via fault relays that halt on overrange, ensuring SEMI-compliant safeties propagate without lag.

Tucked into the gas delivery stratum of your tool stack, it mounts via DIN clips in the manifold enclosure, connecting upstream to the SBC via ribbon cables and downstream to field devices through Molex headers for 50m extensions on shielded Cat5—primed for redundant paths where dual boards cross-check flows, failing to a safe vent state on discrepancy to prevent overpressure bursts. Protocol support spans AMAT’s CVD dialect with Modbus RTU for MES overlays, tunable via the tool console to align with process phases like preheat or deposition dwell.

Its diagnostics are panel-ready: multi-segment LEDs for channel status and error banks, plus a serial debug header that dumps flow traces to a PC, enabling bench tunes without chamber access—no protocol analyzer needed. In a layered setup, it bridges precursor sources upstream and chamber inlets downstream, forging a fluid framework for stratified films—like in low-k dielectric runs where it balances Ar/O2 ratios to minimize RC delays. For an AKT 55K retrofit, the Applied Materials 0100-71304 would harmonize showerhead distributions, offsetting orifice clogs with real-time trims to sustain blanket conformality. This fluid fusion curtails flow mapping, positioning it as the discerning distributor in your deposition domain, melding meter mandates with manifold mastery for attuned, anomaly-free execution.

| Specification | Details |

|---|---|

| Model Number | 0100-71304 |

| Brand | Applied Materials |

| Type | Chamber Distribution Board (AKT 55K CVD) |

| Input Voltage | 24 VDC |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | DIN Rail / Manifold Enclosure |

| Dimensions | 14.7 x 5.15 x 11.4 cm |

| Weight | 0.6 kg |

| Interface/Bus | RS485 Serial / Analog I/O |

| Compliance | SEMI F5, CE, RoHS |

| Supported Protocols | AMAT CVD, Modbus RTU |

| Typical Power Draw | 8.5 W |

Real-World Benefits

Selecting the Applied Materials 0100-71304 endows your AKT systems with a distribution board refined for the unyielding uniformity of CVD cascades, where its 12-bit resolution and 100 Hz polling unearth flow variances down to 1 sccm—yielding film thicknesses holding <0.5% sigma across wafers, which tightens dielectric constants and lifts parametric yields by 1-2% without the recipe walks that conservative calibrations impose. This exactitude isn’t episodic; it endures through runs, enabling stacked depositions where gas blends adapt to substrate warpage, distilling defect densities into defect-free domains across marathon lots.

Process leads laud its prognostic prowess, as ADC thresholds and relay audits surface MFC drifts in the tool chronicle—envision a yield analyst preempting a stoichiometry skew from valve stickiness, recalibrating mid-batch sans purge penalty. The board’s enclosure compatibility streamlines integration rigors, with header-for-header swaps that dovetail with 55K manifolds sans gas line bleeds, accelerating tool turnarounds in throughput-throttled fabs where hours harvest revenue. Spanning fab tenures of 5+ years, it enshrines performance poise with a MTBF over 100,000 hours, its vapor-sealed traces defying silane traces in forelines, so your distribution duties deepen without the decay of drift-prone diodes.

Further, the Applied Materials 0100-71304 fosters flexibility by virtualizing channels in the Synergy map, so precursor additions unfold as firmware flashes rather than frame refits—priming for gate-all-around where flow models mesh with metrology feeds. These layered leverages recast distribution from a deposition drag to a deposition dynamo, paring total chamber costs while elevating the fidelity that fuels your semiconductor forefront.

Typical Use Cases

The Applied Materials 0100-71304 anchors in low-pressure CVD tools like the AKT 55K, clipping into manifold bays to sequence SiH4/Ar flows for poly gates, where its 100 Hz trims hold amid 10 Torr vacuums and dopant pulses—bedrock for process control environments blanketing channels below 20nm, shoring critical system uptime through recipe ramps or vent sequences in logic fabs. In these silane-suffused sanctums, its regulation reinforces high reliability, provisioning setpoint surety that averts whiskers and resistance spikes.

High-density plasma reactors enlist it for oxide fills, modulating O2/TEOS ratios under 500W sheaths and bias swings, sustaining continuous uptime where fast data cycles from QCMs dictate gap-fill grades. Harsh oxygen plasmas and thermal gradients grill its guards, yet it proffers unswerving streams for seamless STI trenches.

In solar cell deposition lines, the Applied Materials 0100-71304 pilots AKT amorphous silicon layers, balancing H2 dilution with plasma powers over 1m² panels—pivotal for used in PERC cells where flow fidelity forestalls shunts and efficiency erodes. Across LPCVD, HDP-CVD, and thin-film PV sectors, this board vitalizes applications yearning for gas governance in glow realms, transmuting sccm surges into scaffolds of stratified supremacy.

0100-71305 – Enhanced rev with 16-bit ADCs for sub-sccm precision in ALD hybrids.

0100-77037 – Interlock companion for safety-gated flow distributions.

0190-15779 – DC supply tie-in for MFC-powered chamber sequencing.

0090-76133 – Synergy SBC add-on for recipe-orchestrated distributions.

0010-30137 – Valve driver PCB for discrete flow actuation extensions.

0100-09145 – RS232 monitor board for flow-logged video overlays.

0300-76027 – Gas manifold sub-assembly for redundant distribution paths.

Before docking the Applied Materials 0100-71304 into your AKT enclosure, sync its firmware hash with the Synergy kernel via the console—version variances can mute channel maps, stranding your flows in default limbo. Scrutinize the Molex headers for pin burrs or residue from shelf life; a precision pick and ohm-out below 0.1Ω thwarts setpoint skews that echo MFC fails. Airflow merits a bay spacer to bleed the 8.5W in sealed hoods, especially near heater coils cresting 55°C—model your sccm totals to validate. Pre-pipe the analogs with a calibrator at 50 Torr, nailing <0.2% linearity sans crosstalk, and shield the RS485 singly at the board to shunt EMI from RF neighbors.

Afield, care cues clairvoyance over constant checks. Biweekly console logs for trim errors—nominal <0.5% deviation signals symmetry, but outliers omen a line leak with a bubble tester. Quarterly header unhooks with anti-stat swabs and ethanol etches on contacts exile corrosion crowns from humid precursors; re-mate at 0.4 Nm to stem thermal walkouts. Annually, deluge with ramp scripts via the debugger to affirm 99.98% repeatability across gas blends, vaulting variances for vintage verifies. If lags loom, invoke AMAT’s remote flow tracer over Ethernet, but these pulses pose the Applied Materials 0100-71304 as a stream sentinel, steering scrutiny to sooths over scrubs.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626